Checkline TI-25M User Manual

Page 5

– 5 –

3.4 Keypad

The TI-25M is supplied with a membrane keypad mounted

on the front of the instrument body. It consists of six (6)

keys, each performing one or more functions as described

below.

The CAL key is used to enter and exit the Tl-25M’s two

Calibration modes. The Acoustic Velocity Calibration mode is

used to adjust the acoustic velocity for the material to be mea-

sured. The Measurement Calibration mode is used to increase or

decrease the displayed thickness reading to calibrate to a known

thickness value.

The INCH/MM key is used to change the measuring units from

inches to mm. Each time the key is pressed the units will change

from one to the other.

The UP arrow key performs the following two functions:

1. When in the Calibration mode, pressing the UP arrow

key will cause the numeric values to increase. By

pressing and holding the key, the numbers will change

more rapidly.

2. When in the Measuring mode, pressing the UP arrow key

will turn the Scan Measuring mode on and off each time

it is pressed. The display will momentarily flash indicating

whether the Scan mode is on or off.

The DOWN arrow key performs the following two functions:

1. When in the Calibration mode, pressing the DOWN

arrow key will cause the numeric values to decrease. By

pressing and holding the key, the numbers will change

more rapidly.

2. When in the Measuring mode, pressing the DOWN

arrow key will change the Display Backlight mode from

OFF to AUTO to ON. The currently selected mode will

momentarily flash on the display.

The PROBE ZERO key is used to “zero” the probe in a similar

way as a micrometer is “zeroed” before use. If the tool is not

zeroed correctly, the measurements will not be accurate.

The ON/OFF key is used to turn the power on as well as turning

the power off. If the Tl-25M is idle for five (5) minutes the gauge

will automatically power off.

CAL

INCH

MM

PROBE

ZERO

ON

OFF

CAL

PROBE

ZERO

INCH

MM

ON

OFF

– 20 –

6. If two materials are press-fitted or laminated together, the gauge

will only measure the thickness of the sample that contacts the

probe.

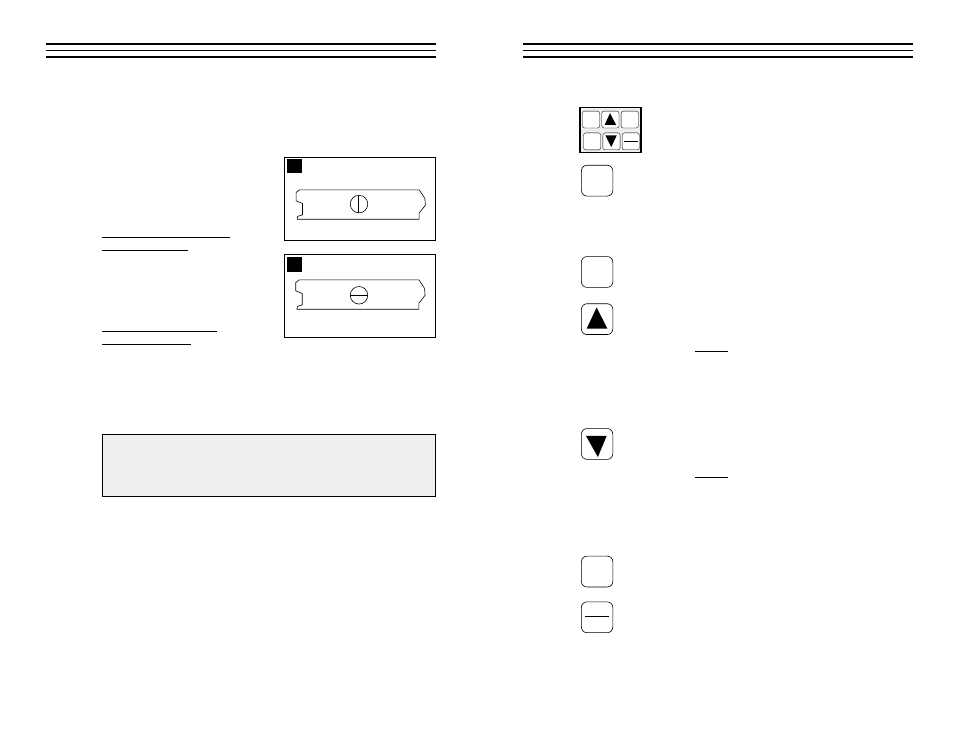

8.2 Measurements Of Pipes Or Cylindrical Parts

When using the TI-25M to

measure the wall thickness of

a pipe, the orientation of the

probe is very important to obtain

accurate readings.

Pipe diameter is greater than

4 inches (100 mm):

Position the probe so the centerline of

the probe wearface is perpendicular to

the long axis of the pipe as shown in

illustration “A.”

Pipe diameter is less than

4 inches (100 mm):

Two measurements should be performed at the same location, one with the

centerline of the probe perpendicular to the long axis and one parallel

(illustration “B”).

The smaller (thinner) of the two measurements should be used as the

actual wall thickness at the measurement location.

Additionally, on applications on pipe diameters less than 3 inches,

we recommend using the optional V-Block fixture which helps

maintain stable probe placement on the rounded measuring surface.

A

B

Parallel

Perpendicular