Checkline R55 User Manual

Page 3

Plug & Test

TM

Smart Force & Torque Sensors

User’s Guide

2

1 OVERVIEW

1.1 General Overview

Several series of Plug & Test

TM

sensors are available to accommodate numerous force and torque

measurement requirements – from 0.25 to 10,000 lbF (1 N to 50 kN) of force, and from 10 ozFin to 5,000

lbFin (7 Ncm to 550 Nm) of torque. These sensors can be handheld or mounted to a fixture or test stand

for more sophisticated testing requirements.

Plug & Test

TM

sensors are used with Mark-10 7i, 5i, and 3i indicators. They may be disconnected from

one indicator and connected to another without the need for re-calibration or re-configuration. All such

data is saved within a PCB located inside the smart connector.

The model number, serial number, and capacity of the sensor are identified in the rectangular label

located on the Plug & Test

TM

connector. The model and serial numbers are also identified in the

Information screen of the indicator. Refer to the indicator user’s guides for more information.

1.2 Accuracy and Resolution

Indicator accuracy must be combined with sensor accuracy to determine the total accuracy of the system.

Since sensors may be used with the 7i, 5i or 3i indicators, the accuracy of the indicator being used must

be identified and taken into account, as follows:

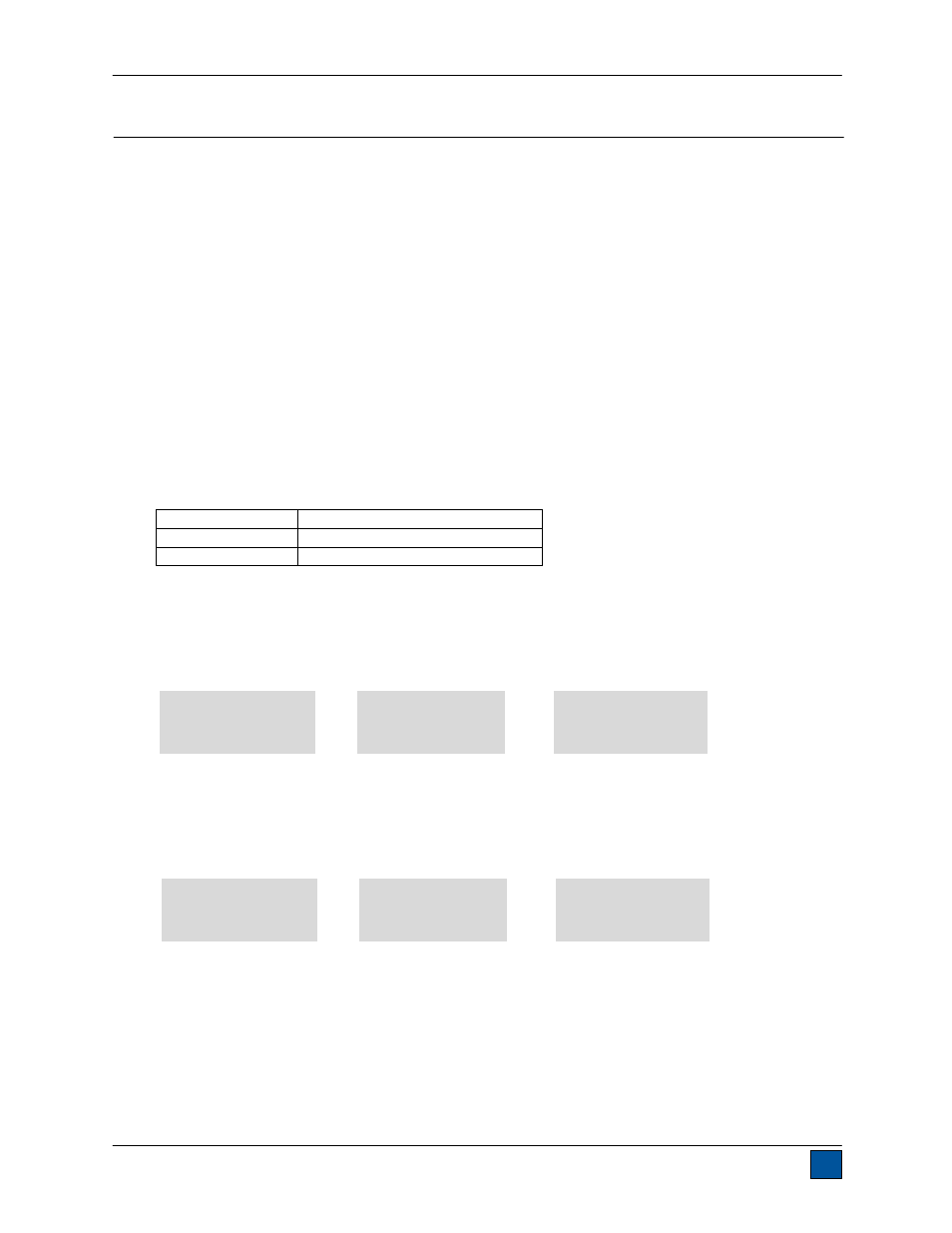

Indicator Model

Accuracy

7i / 5i

±0.1% of full scale

3i

±0.2% of full scale

The total system accuracy can be calculated by adding the sensor accuracy and indicator accuracy.

Refer to the following examples:

Example 1

Model MR01-100 sensor with Model 5i Indicator

MR01-100

±0.15% of full scale

+

5i

±0.1% of full scale

=

Total

±0.25% of full scale

This translates into a fixed error of up to:

0.25% x 100 lbF = 0.25 lbF

Example 2

Model MR50-50Z sensor with Model 3i Indicator

MR50-50Z

±0.35% of full scale

+

3i

±0.2% of full scale

=

Total

±0.55% of full scale

This translates into a fixed error of up to:

0.55% x 50 ozFin = 0.275 ozFin

Because accuracy is defined as a percentage of full scale, the fixed error is possible anywhere on the

scale from 0 to the capacity. As such, this value represents an increasingly large error as percentage of

reading towards the low end of the scale. It is, therefore, recommended that a sensor is selected with

capacity as close as possible to the expected load.