Checkline R55 User Manual

Page 13

Plug & Test

TM

Smart Force & Torque Sensors

User’s Guide

12

10 SERIES R51 TORQUE SENSORS

10.1 Unpacking and Assembly

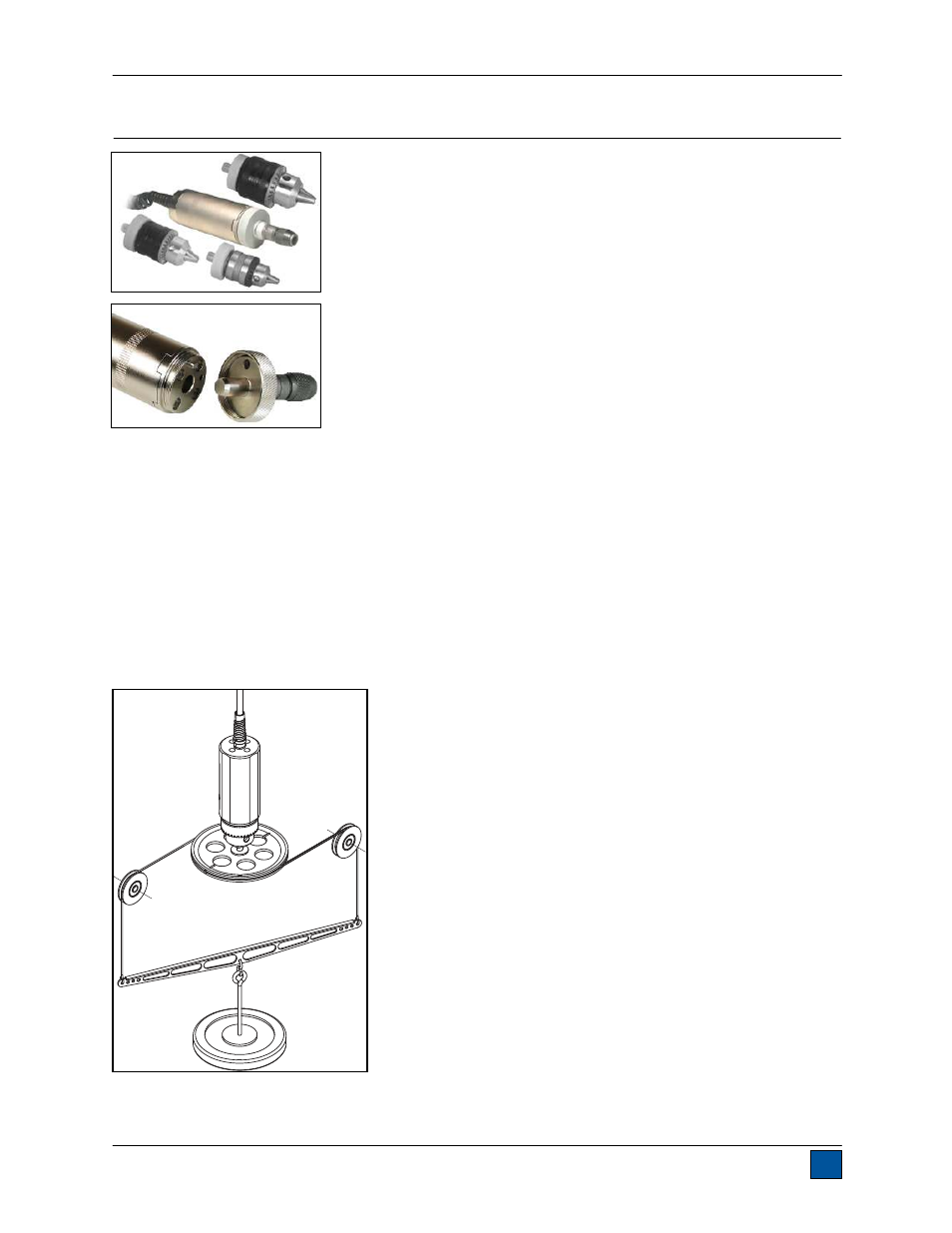

Carefully remove the sensor from the box. Series R51 sensors are

available with three interchangeable chuck attachments and bit holder.

To attach the chuck or bit holder, align the pin located on the end of the

sensor body with the hole located on the attachment (see Fig. 10.1).

Thread the ring onto the sensor body to keep the attachment in place.

10.2 Overview

Designed for clockwise and counter-clockwise torque testing. The sensor

may be handheld or mounted to a test stand, fixture, or other equipment.

Bits or fixtures may be placed in the chuck, although extra care should be

taken when handling low capacity models.

10.3 Specifications

Accuracy:

±0.2% of full scale

Safe overload:

MR50-10Z - MR50-50Z: 300% of full scale

MR50-12 - MR50-100: 150% of full scale

Chuck opening range: MR50-10Z - MR50-50Z: 0.062 - 0.375 in [1.6 - 9.5 mm]

MR50-12 - MR50-100: 0.078 - 0.5 in [2.0 - 12.7 mm]

Operating temperature: 40ºF – 100ºF [5ºC – 38ºC]

Operating humidity:

96% max. (non-condensating)

Weight:

From 1.4 lb [0.6 kg]

10.4 Calibration

Calibration should be performed in a vertical orientation, especially for sensors with capacities of 50 ozFin

[35 Ncm] or less. Horizontal orientation subjects the sensor to side loads resulting from the weight of the

chuck and attachments. Such side loads can be significant enough to skew the readings out of tolerance.

The illustration below depicts a recommended vertical setup:

For further calibration instructions, refer to the indicator’s user’s guide.

Fig. 10.1

The attachment and main sensor

body mate with a pin and threaded

ring.