8 troubleshooting, 1 malfunctions and their remedy, Malfunctions and their remedy – BUCHI Multivapo P-12 User Manual

Page 60: 8troubleshooting, 8 .1 malfunctions and their remedy

8 Troubleshooting

60

Multivapor™ Operation Manual, Version E

8

Troubleshooting

The following chapter describes how to resume operation of the instrument in the event of any minor

problem. It will list some possible occurrences, their probable cause and suggests how to remedy the

problem. The troubleshooting table below lists possible malfunctions and errors of the instrument and

describes operator enabled courses of action to correct some of those problems by him or herself.

The appropriate course of action is listed in the column “Corrective measure”.

The elimination of more complicated malfunctions or errors is usually performed by a BUCHI technical

engineer who has access to the official service manuals. In this case, please refer to your local BUCHI

customer service agent.

8 .1

Malfunctions and their remedy

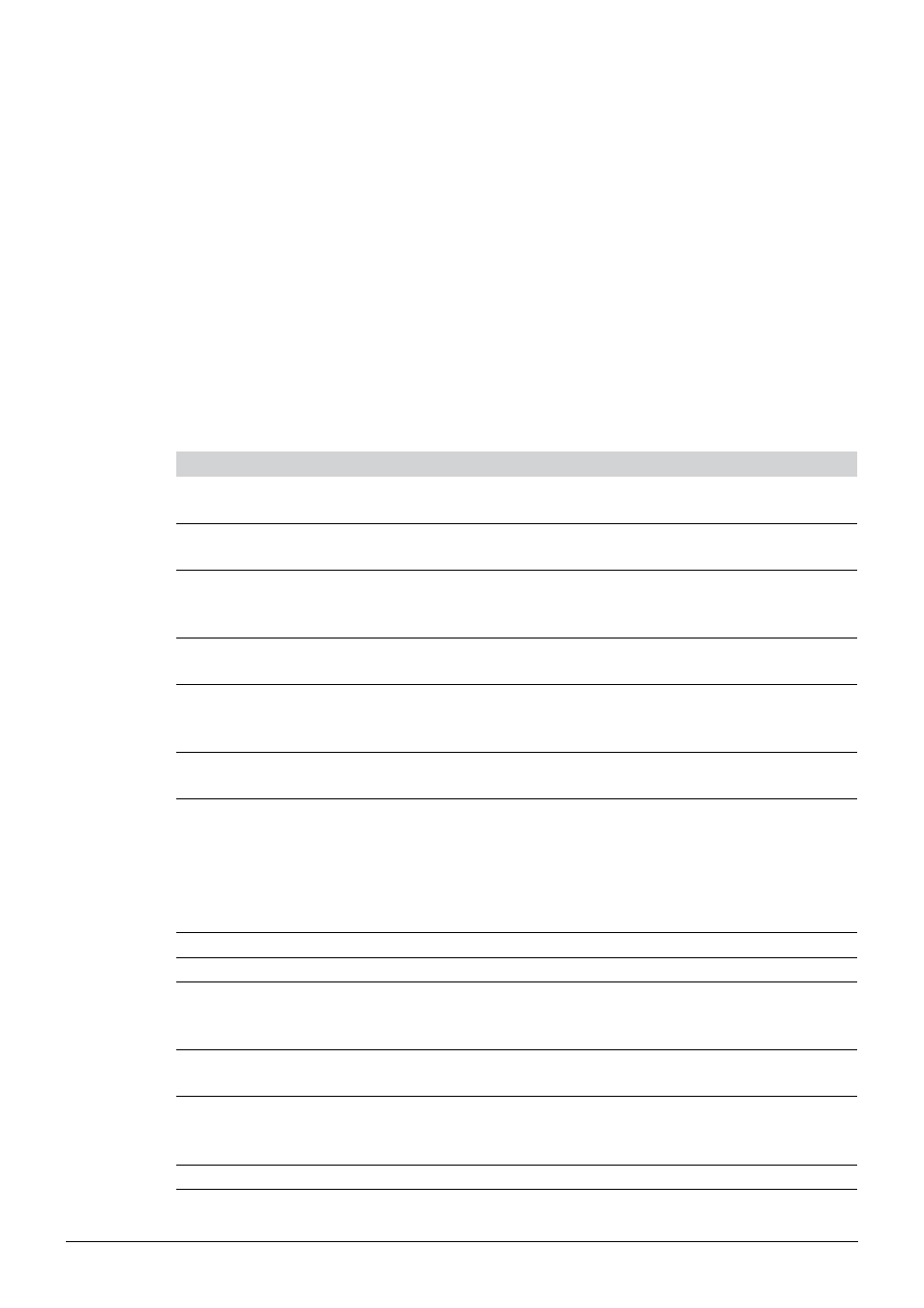

Table 8-1: General malfunctions and their remedy

Malfunction

Possible cause

Remedy

Instrument does not work

Main switch off

Switch on main switch

Instrument is not connected to mains

supply

Check mains connection

Fuse defective

Replace the fuse. If this malfunction

occurs again, contact the BUCHI

customer service.

Instrument does not heat

Over-temperature protection was

burned

Heating plate must be replaced.

Contact the BUCHI customer service.

Fuse defective

Replace the fuse. If this malfunction

occurs again, contact the BUCHI

customer service.

Temperature is not adjustable

Instrument is set to the preset

temperature mode

Follow the instructions in chapter

6.1.1

Rotation is not smooth

Uneven and/or unstable surface or 6

position rack on a P-12 instrument

Adjust the height of the feet and/

or change location. Do not use a 6

position rack with a P-12 instrument

(see label on the front panel) with

rotations higher than 8. Place the

rack on a P-6 platform.

System leaks

See chapter 5.7.1

See chapter 5.7.1

Vacuum is not reached

System leaks

See chapter 5.7.1

Back evaporation from the distillate

Empty the receiving flask or cool the

distillate (e.g. with an ice bath or the

refrigerated receiver)

Vacuum pump is inefficient

Check the characteristics and

leaking rate of the vacuum pump

Distillation “died out”

Solvent mixtures; initial overheating

of the sample

Decrease the pressure until the

distillation starts again or increase

the temperature