2 pressure gradients (v-855) – BUCHI Multivapo P-12 User Manual

Page 52

6 Operation

52

Multivapor™ Operation Manual, Version E

6 .5 .2

Pressure gradients (V-855)

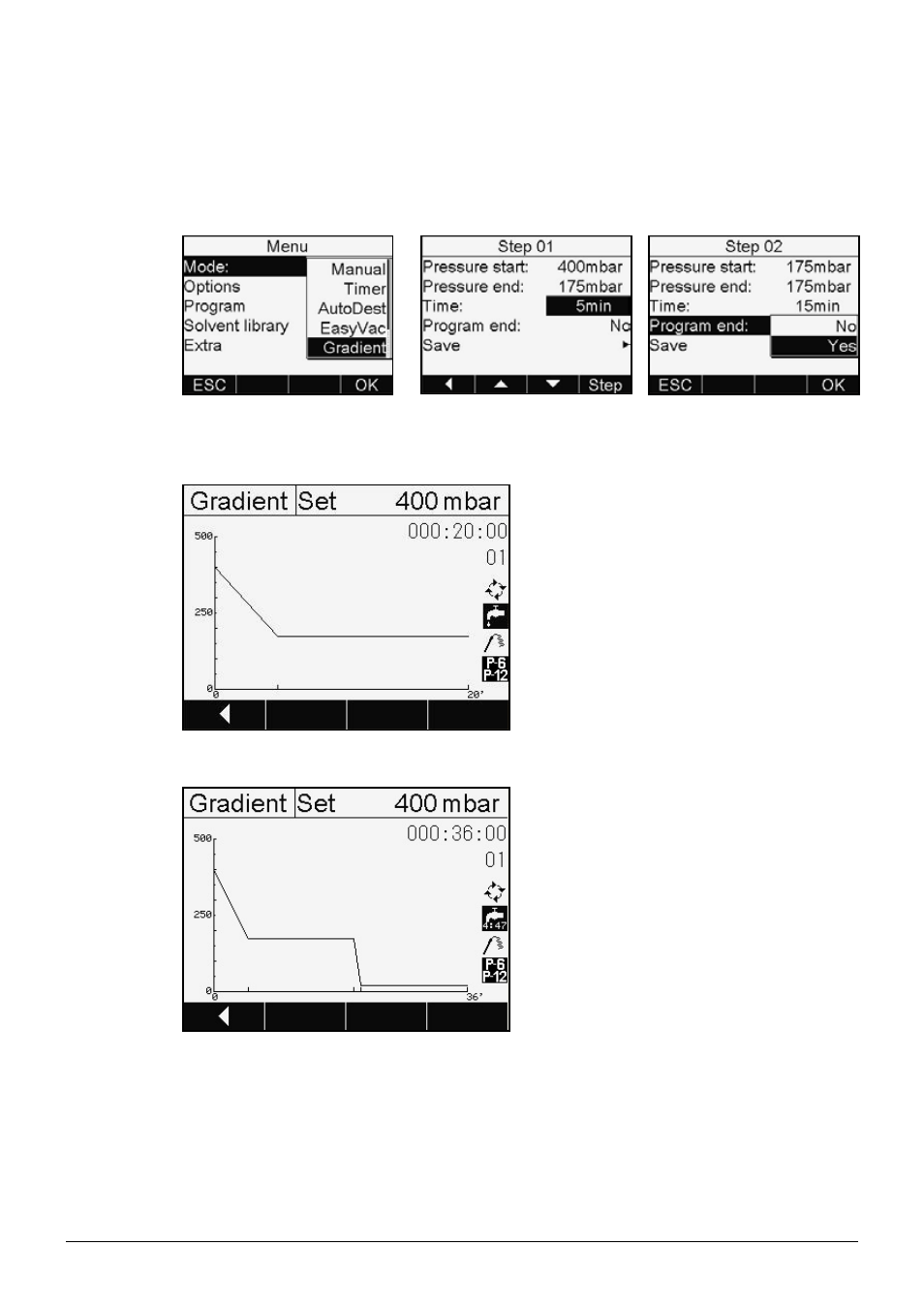

Setting the pressure manually to the boiling point involves the risk of boiling retardation. To minimize

this risk, it is strongly recommended to program a pressure gradient that slowly converges to the opti-

mized ultimate vacuum. This is achieved as follows:

• Select the Gradient mode.

• Program the first step.

• Program additional steps and

terminate the programming

by selecting “Yes”.

The corresponding gradient can be stored for fu-

ture recall and displayed at any time. For further

information please consult the operation manual

of the vacuum controller.

Fig. 6.33: Pressure gradient for distillation of ethanol at 65 °C (instrument setting)

It is often desirable to dry any remaining solid

sample immediately after solvent evaporation.

For routine procedures it is advisable to imple-

ment this step directly into the gradient program.

This reduces the amount of instrument handling

and keeps supervision to a minimum.

Fig. 6.34: Example of a gradient setting with a drying step subsequent to the solvent evaporation

NOTE

A direct drying step without interruption of the distillation process is only possible if the distilled

solvent is kept at low temperature, i.e. below the corresponding boiling point of the ultimate vacuum

setting. This is achieved by using an ice bath or the optional refrigerated receiver in combination with

a recirculating chiller.

Pressure gradients are also an ideal tool for complex mixtures with low-boiling components which