6 optimizing the distillation conditions, Optimizing the distillation conditions, 6 .6 optimizing the distillation conditions – BUCHI Rotavapo R-215 User Manual

Page 47

6 Operation

47

R-210/215 Operation Manual, Version F

ATTENTION

Risk of overflowing.

• When you are operating with a 5 l heating bath, make sure that the controller is configured in a

way that the flask is not automatically submerged into the heating bath to avoid an overflowing of

the heating bath due to displacement. Introduce the flask manually instead.

• After the set vacuum has been reached, wait for about 1–2 minutes to see whether distillation

begins.

• If the distillation does not start, optimize the parameters (decrease the pressure gradually or

increase the bath temperature).

• Both possibilities lead to an increased distillation capacity, see also chapter 6.6.

6 .6

Optimizing the distillation conditions

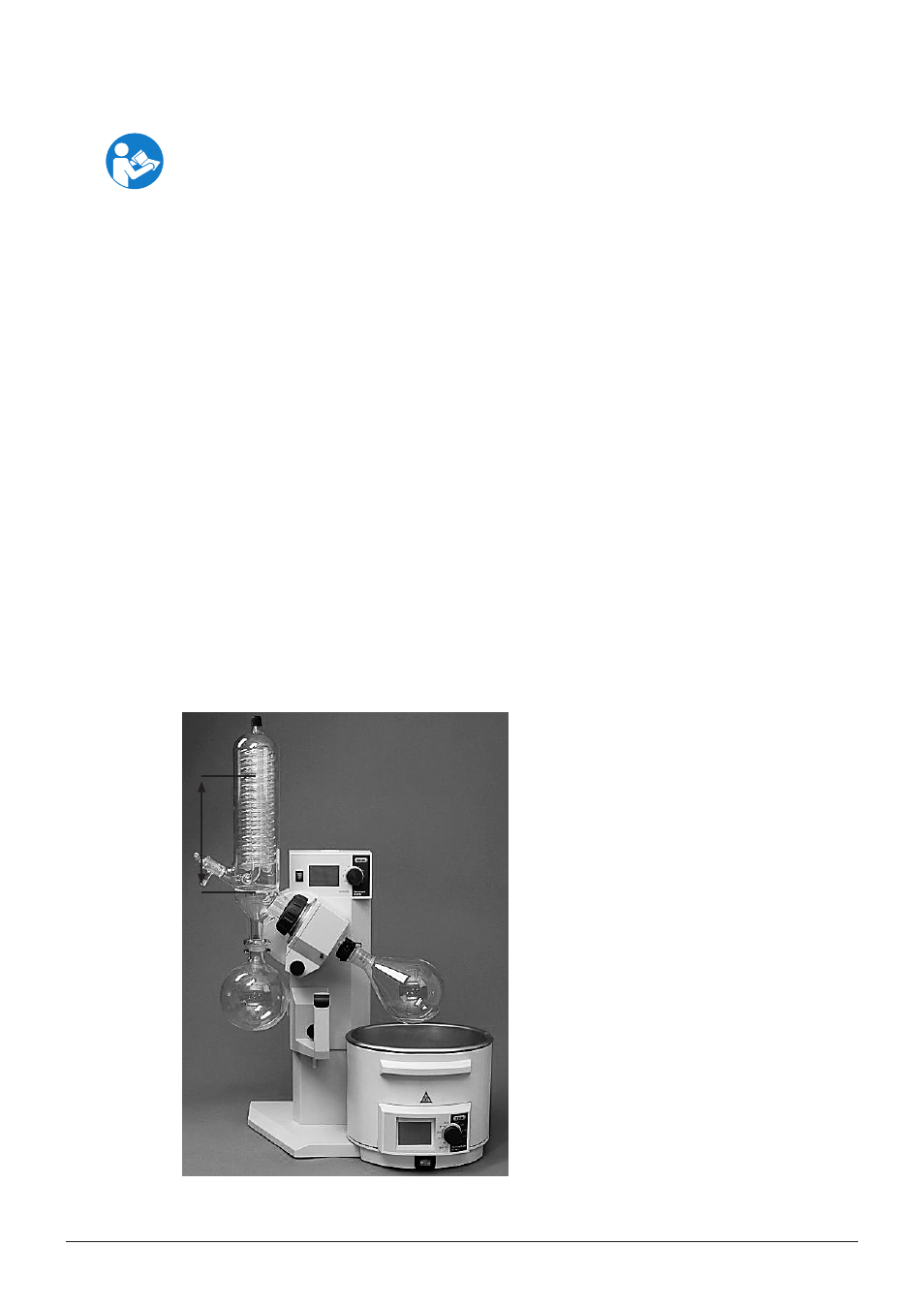

Depending on the solvent being distilled the distillation might have to be re-optimized. In the optimized

case, the condenser should be steamed up to between 2/3 to 3/4, see figure below.

If this is not the case, there are two possibilities to optimize the distillation:

• When the heating bath has reached 60 °C slowly reduce the pressure. Thus, the boiling point of

the solvent is reduced and

Δ T

1

increases resulting in an increase of distillation capacity.

• When the heating bath has reached 60 °C increase the bath temperature. Thus

Δ T

1

increases

resulting in an increase of distillation capacity as well.

NOTE

When the bath temperature is increased, not all of the additional energy is used for distillation but a

major part is discharged into the environment due to the increasing difference between heating bath

and the ambient temperature.

3/4

Fig. 6.6: Optimal condensation area of a condenser