Fuel gas supply, Electrical supply, Verify burner components – Beckett CG4 User Manual

Page 9: Verify burner selection, Explosion, fire, and gas leak hazard

9

CG4 Burner Manual

Section: INSPECT/PREPARE INSTALLATION SITE

Fuel Gas Supply

Explosion, Fire,

Asphyxiation Hazard

Leaking gas could result in asphyxiation,

explosion, or fire hazard.

Prior to burner installation all gas supply piping must be

inspected, tested and purged in accordance with the

requirements of the National Fuel Gas Code ANSI Z

223.1 (NFPA 54).

The burner valve must not be exposed to pressure

exceeding 1/2 PSI under any circumstances.

Insure that the supply gas pipe size is capable of

providing at least 4.5” W.C. pressure to the burner gas

train inlet at the burner’s full capacity rating. Refer to

Tables 2 and 3.

Explosion, Fire, and Gas

Leak Hazard

A Drip Leg is required in Gas Supply

Piping. Foreign matter could lodge in gas

valve cutoff seals, resulting in gas leak-

through, explosion or fire.

Insure that a full-size drip leg or dirt pocket has been

installed in the piping directly ahead of the main shutoff

valve to capture foreign matter.

Electrical Supply

Check the nameplate on the burner to verify that the

power connections available are correct for the burner.

Refer to

Figure 2 on Page 5. All power must be

supplied through a disconnect switch fused at 20A

maximum and comply with the latest edition of National

Electric Code NFPA 70 (Canada CSA C22.1) and all

other local or applicable codes.

Verify Burner Components

Your CG4 burner is shipped in two boxes. Verify that

you received all the necessary components.

The larger box contains:

○ The burner chassis

○ The literature package, which includes the burner

manual

○ The gas valve

○ A small parts bag, containing a reducing tee, a pipe

plug, a union and a baffle (P/N 5880)

The smaller box contains:

○ The air tube

○ The burner head and its (2) mounting screws

○ A blank air band (only packaged with tubes using the

F3G head)

○ A box containing the manifold assembly, the natural

gas orifices, an O-ring, a packet of O-ring lubricant

and 10 mounting screws.

Verify Burner Selection

If the burner is supplied as an original equipment part

of a boiler or furnace appliance the information in this

section may be disregarded. Instead, use the appliance

manufacturer’s specifications.

Verify that the proper burner chassis and air tube

assembly have been selected.

○ Determine the appliance’s design firing rate from the

appliance rating plate. The appliance rating plate will

probably have an input rating and an output rating.

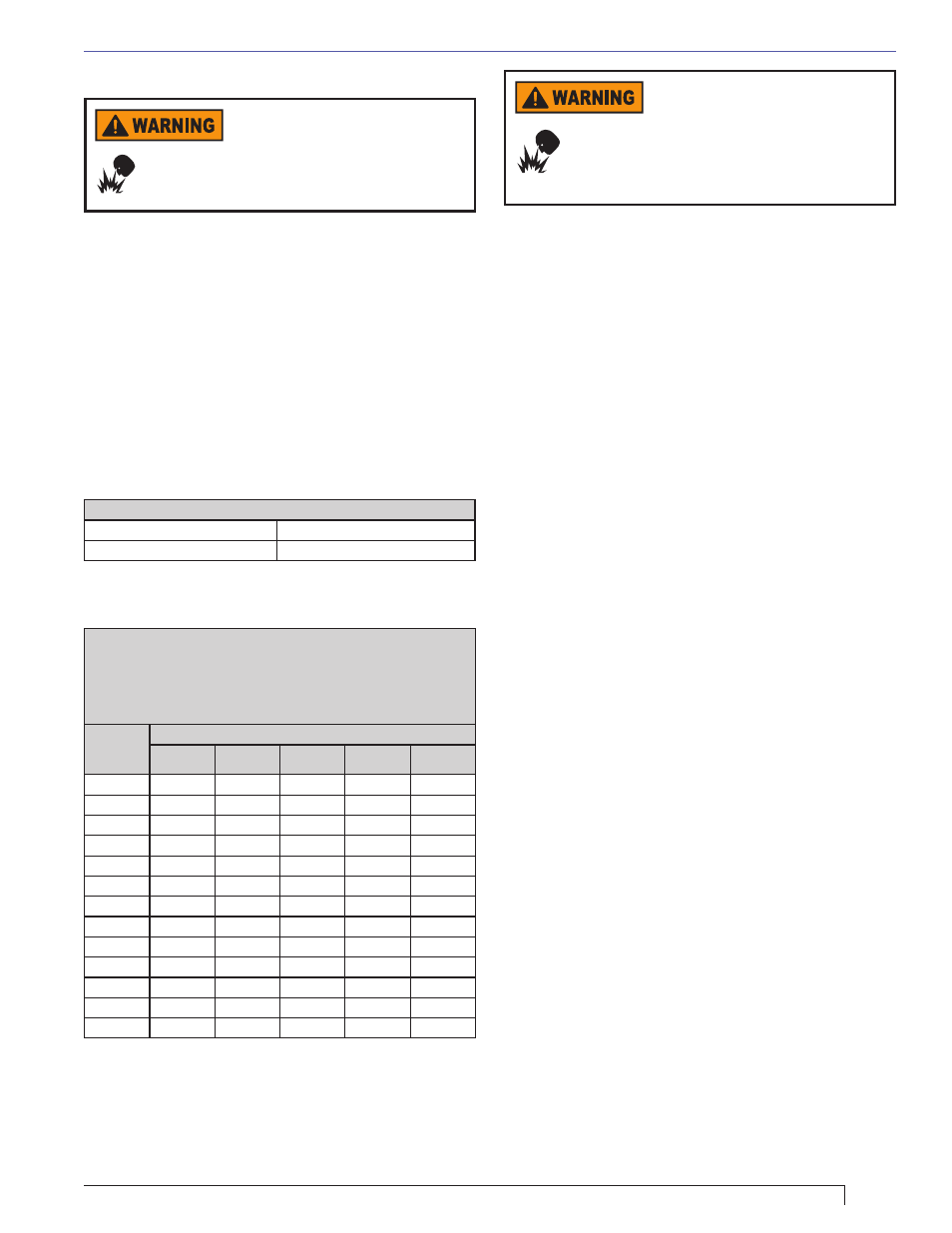

Table 3 – Gas supply piping capacity, CFH

Schedule 40 metallic pipe with 0.50 psi or less inlet pressure

and 0.30” W.C. pressure drop

Maximum capacity in cubic feet of gas per hour (CFH). Natural

gas with 0.60 specific gravity.

Pipe

Length

(ft.)

Pipe size (inches) IPS

1/2”

3/4”

1”

1-1/4”

1-1/2”

10

132

278

520

1050

1600

20

92

190

350

730

1100

30

73

152

285

590

890

40

63

130

245

500

760

50

56

115

215

440

670

60

50

105

195

400

610

70

46

96

180

370

560

80

43

90

170

350

530

90

40

84

160

320

490

100

38

79

150

305

460

110

34

72

130

275

410

120

31

64

120

250

380

150

28

59

110

225

350

Table 2

Gas Supply Pressure Requirements (Natural or Propane)

Maximum

14” WC (1/2 PSI)

Minimum

4.5” WC

If the gas supply pressure is not correct, it must be

corrected before starting the CG4 installation. Contact

your gas utility or qualified contractor.