Mount the burner, Connect gas piping – Beckett CG4 User Manual

Page 16

16

Section: MOUNT THE BURNER

Connect Gas Piping

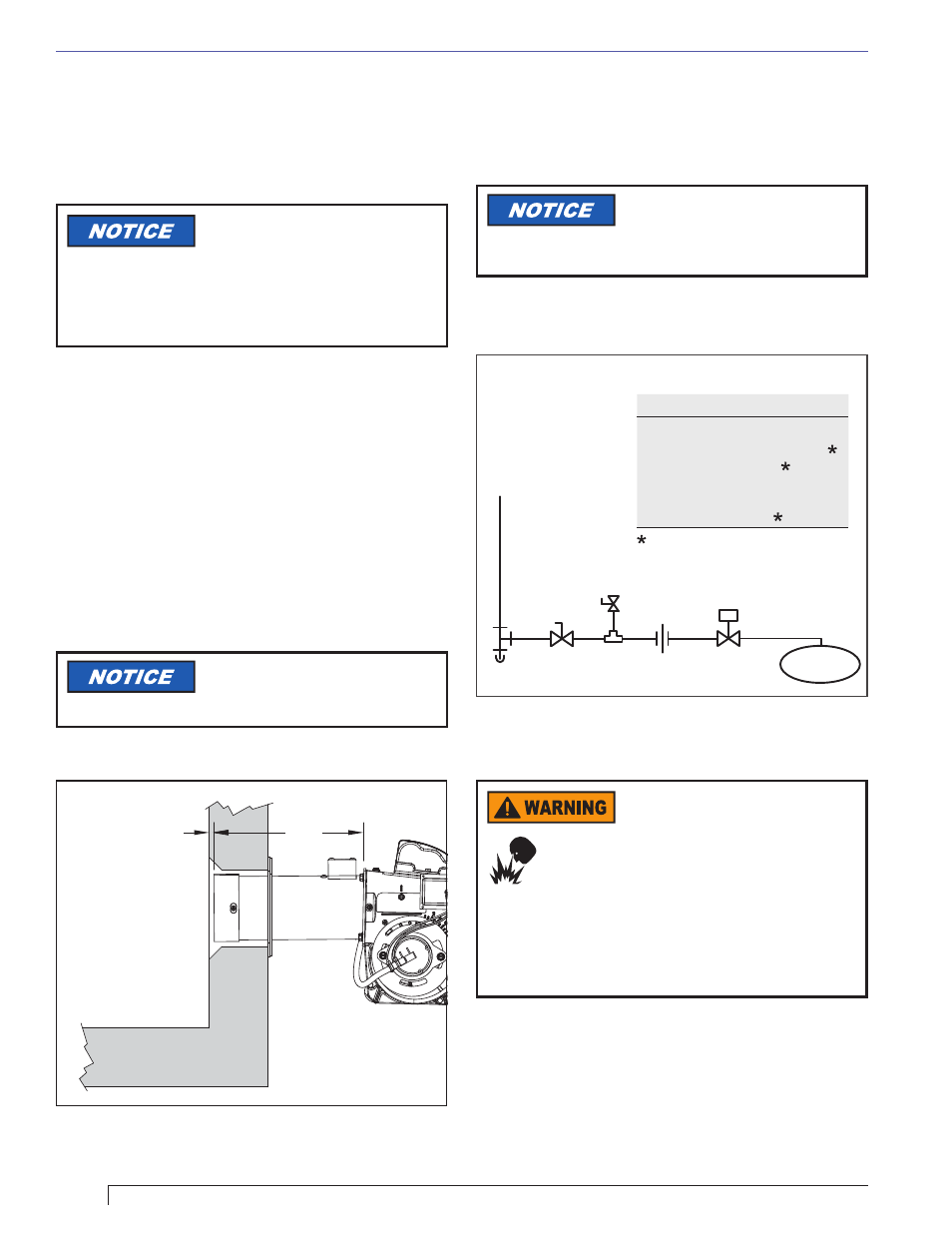

Install the test cock tee, its plug, and the union (provided

with the burner) into the supply piping and connect them

to the burner valve and manifold (

Figure 12).

Gas supply piping must be

structurally supported

independant of the burner. The burner manifold and

gas valve are not designed to support piping loads.

Mount the Burner

Mount the burner to the appliance. The burner specified

for packaged equipment will have a flange welded for the

required insertion. Follow the appliance manufacturer’s

instructions for mounting.

Protect the Air Tube

from Overheating

Overheating could cause damage to the air tube

and other combustion components leading to

equipment malfunction and impaired combustion

performance.

1. Verify the Burner’s Insertion Depth

The end of the air tube should be set back ¼”

from flush with the refractory inside wall to prevent

damage from overheating (See

Figure 11).

The end of the air tube must not extend into the

combustion chamber unprotected unless it has

been factory-tested and specified by the appliance

manufacturer.

2. Bolt the burner to the appliance using the factory-

mounted flange and gasket.

3. Provide support under the burner if required.

Some Local codes require the

burner to have a stand. If this is

required use Beckett Part #5685 Pedestal Kit.

Figure 11

9.5”

1/4”

Figure 12 – Typical Gas Piping Layout

U

MSC

DL

GV

BURNER

TC

KEY

Abbrev.

Item Description

MSC

Main Shutoff Cock

TC

Test Cock

U

Union

GV

Gas Valve

DL

Drip Leg

Provided by Installer

TEE

Explosion and Gas Leak

Hazard

Provide Over-pressure Protection

The National Fuel Gas Code, ANSI Z223.1 (NFPA

54) and ASME CSD-1 require that if gas pressure

entering the building exceeds the rating of any gas

train component an overpressure protection device

must be installed.