Combustion air supply, Buildings with adequate air infiltration, Buildings with less than adequate air infiltration – Beckett CG4 User Manual

Page 8: Clearances to burner and appliance

8

Section: INSPECT/PREPARE INSTALLATION SITE

Combustion Air Supply

Some local codes and

gas utilities require the

installation of a CO detector, this is

strongly recommended in all

applications.

Carbon Monoxide

Hazard

Do not block combustion air inlet. Failure to

provide adequate air supply could seriously affect

the burner performance and result in damage to

the equipment and emission of poisonous carbon

monoxide gas.

Buildings with Adequate Air Infiltration

In many cases, a burner operating in an unconfined

space of a conventional frame, brick or stone building

will receive adequate air supply from leakage in the

building itself. But if the burner is located in a confined

space such as a furnace or boiler room, that space

must have one permanent opening toward the top of the

space and one near the bottom of the space.

Each opening must have a free area of not less than one

sq. in. per 1,000 BTU per hour of the highest input rating

listed for the appliance (refer to NFPA 54 & 58).

Remember to take the total input of all air-using

appliances into consideration when figuring the

openings. The openings must connect with the inside of

the building, which should have adequate infiltration from

the outside.

As an example:

If a gas burner was firing at 175,000 BTU/Hr and a water

heater was firing at 70,000 BTU/Hr, in an enclosed room

in a building each opening in the enclosure should be

245 sq. in. (245,000/1,000 x 1 sq. in. = 245 sq. in.) A

245 sq. in. opening would typically be 10” x 25” or 16” x

16”.

Buildings with Less Than Adequate Air

Infiltration

If the burner is located in a tightly constructed building

where there is inadequate outside air infiltration, outside

combustion air must be supplied by some other means.

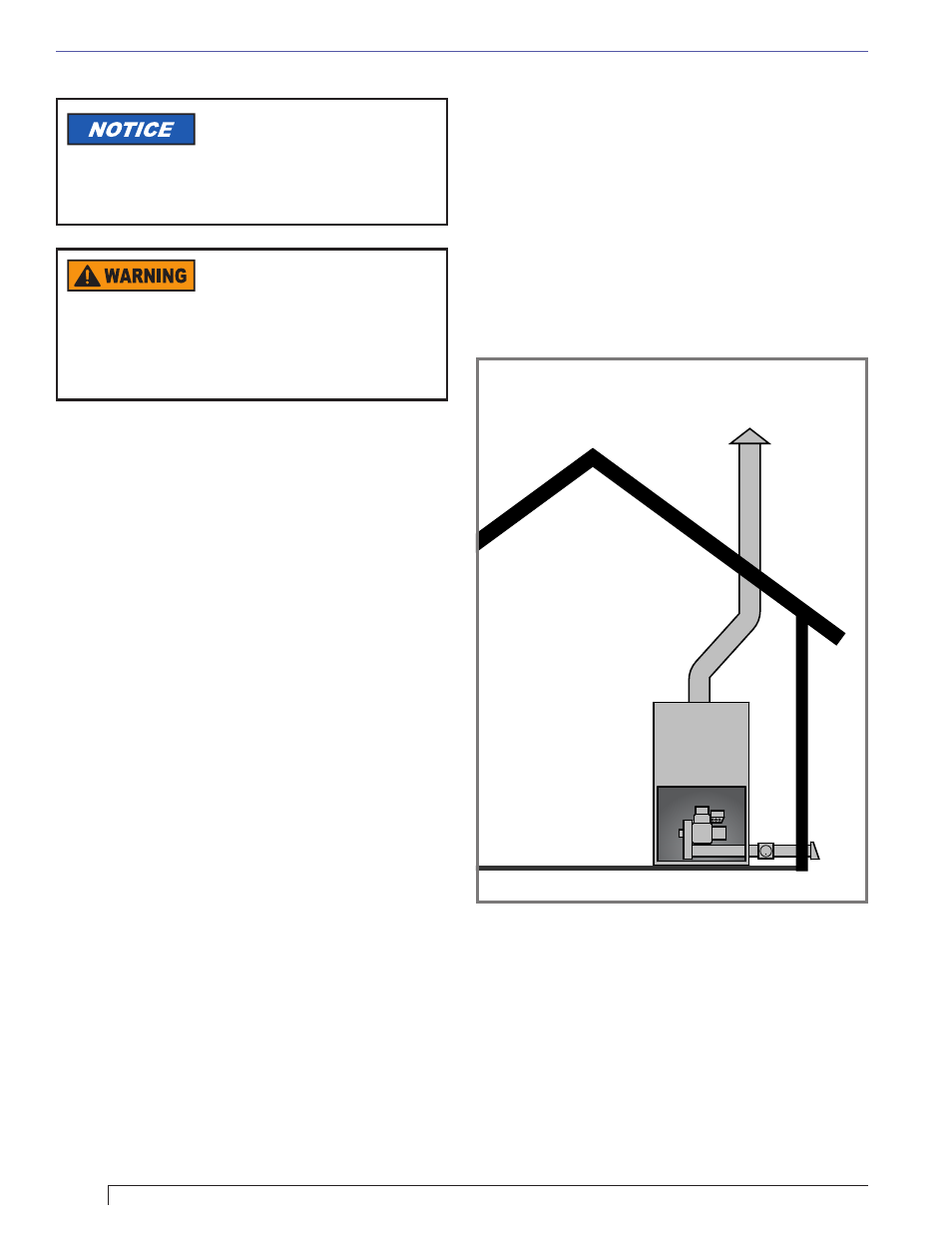

Figure 5 – Outdoor Air Ducted to Burner

One method to accomplish this is through a permanent

opening(s) in an exterior wall. The opening, or openings,

must have a total free area of not less than one sq. in.

per 5,000 BTU per hour. All appliances must be taken

into consideration. Refer to NFPA 54 & 58.

Another method is to supply outside air directly to the

burner through round, smooth duct work (See

Figure

5). Some manufacturers offer accessories which allow

outside combustion air duct work to be coupled to the

burner. These kits must meet the engineered system

requirements of NFPA54. For safety reasons it is

important that you comply strictly with their installation

instructions.

Clearances to Burner and Appliance

○ Provide space around burner and appliance for easy

service and maintenance.

○ Check minimum clearances against those shown

by the appliance manufacturer and by applicable

building codes.

○ The recommended clearance around the burner

itself is 12” minimum for service access.