Verify the firing rate – Beckett CG4 User Manual

Page 20

20

Section: START THE BURNER

Call for Heat. Verify that burner fires up and the

gas valve closes. After control locks out, flame

shall go off.

6. Turn power off and reattach sensor wire. Turn

power back on. Control should reset. Initiate Call

for Heat.

7. After you have observed main flame for a brief time,

press the reset button on the control for 1 second

to shut down and re-start the burner. Monitor the

flame and safety shutoff valves to assure that

shutdown is controlled by the valves and that they

operate properly. With this test passed, you may

safely initiate automatic start-ups on subsequent

cycles.

8. While the burner is firing, examine the vent system

for evidence of leaks, obstructions, and for correct

function of the barometric draft control. Leak test

all gas piping from the burner to the utility supply

piping. If leaks are found, correct them immediately.

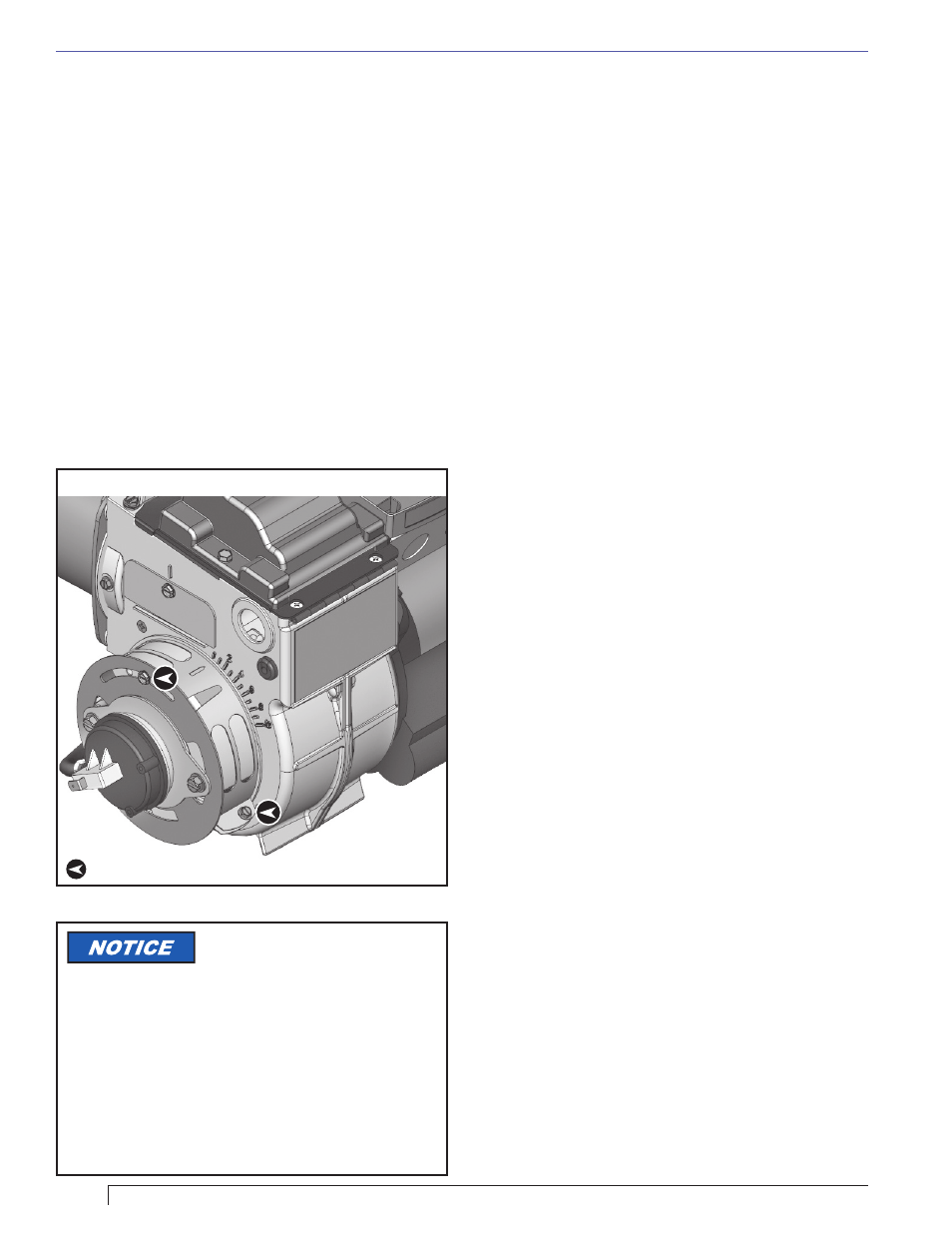

Figure 14 – Shutter and Band

= Tighten locking screws securely after adjustments have been made

The shutter and band both

control the amount of flow area

available for air inlet to the burner. The greater their

combined flow area, the higher the firing rate. The

primary differences between the two are their ease of

adjustment and their total airflow area. The shutter

turns more easily and has a smaller net flow area. As a

result we have found the shutter to be better suited for

low rate adjustments, and the band better suited for high

rate adjustments. We recommend that at low rates the

band be left completely closed until the shutter has been

fully opened, and that for higher rates the shutter is left

completely open as the band is opened.

Verify the Firing Rate

The primary method for verifying the burner’s firing

rate, for either natural gas or propane, is to assure that

the correct fuel orifice is properly installed and that the

gas valve outlet pressure is accurately set to 3.5” water

column.

1. Turn off electrical power to the burner and close the

main shutoff cock supplying gas to the burner.

2. Remove the plug from the outlet pressure tap on

the outlet end of the gas valve (

Figure 15) and

install a hose barb fitting and manometer.

3. Turn on system power and gas supply and initiate a

call for heat to light the burner.

4. The manometer should show 3.5” water column

pressure. If it does, turn off the burner and skip

ahead to step 6. If it doesn’t, let the burner continue

to run and adjust the gas valve pressure regulator

in the following steps.

5. Remove the regulator cover screw (see

Figure

15) from the regulator adjustment tower and turn

the regulator adjust screw clockwise to increase

pressure or counterclockwise to decrease pressure.

Set the regulator to produce a 3.5” water column

reading in the manometer. Check the appliance

breech or draft setting and adjust if necessary as it

can affect the setting. Replace the regulator cover

screw.

6. Turn off the burner and turn off all electrical power

to the system.

7. Remove the manometer hose and barb fitting from

the gas valve outlet pressure tap.

8. Replace the outlet pressure tap plug and tighten

(clockwise 40 – 60 in-lbs.).

9. Turn on system power and start the burner.

10. Check for leaks at the gas valve outlet pressure tap

plug using a leak detection solution or soapsuds.

Bubbles forming indicate a leak. SHUT OFF GAS

AND FIX ALL LEAKS IMMEDIATELY.

If the burner is firing natural gas it may be possible to

verify the firing rate by “clocking” the gas meter:

1. Locate the gas meter and examine its display

to be sure that you can determine a 1 cubic foot

usage of gas and that the meter is temperature

compensated.

2. Contact the gas utility to find the

heating value

of the gas. It can vary from about 950 BTU/Ft

3

to

about 1,100 BTU/Ft

3

.

3. Examine the gas piping to know of any other gas

appliances connected to it. Turn them off so that

only this burner is using gas from the meter.