Check operation and safety controls – Beckett CG4 User Manual

Page 21

21

CG4 Burner Manual

Section: START THE BURNER

4. Start the burner and use a stopwatch to measure

the number of

timed seconds it takes for the

burner to fire 1 cubic foot of gas.

5. Calculate the firing rate in BTU/Hr. using the

following equation:

Firing rate BTU/Hr. = Heating value (BTU/Ft

3

) x

3,600 ÷ Timed seconds

For example, if the heating value is 1,050 BTU/Ft

3

and you timed 1 cubic foot of gas at 42 seconds

then firing rate BTU/Hr = 1050 x 3,600 ÷ 42 which

calculates to 90,000 BTU/Hr.

If the burner is firing LP gas, a meter is usually

not available. Contact your LP supplier for

recommendations.

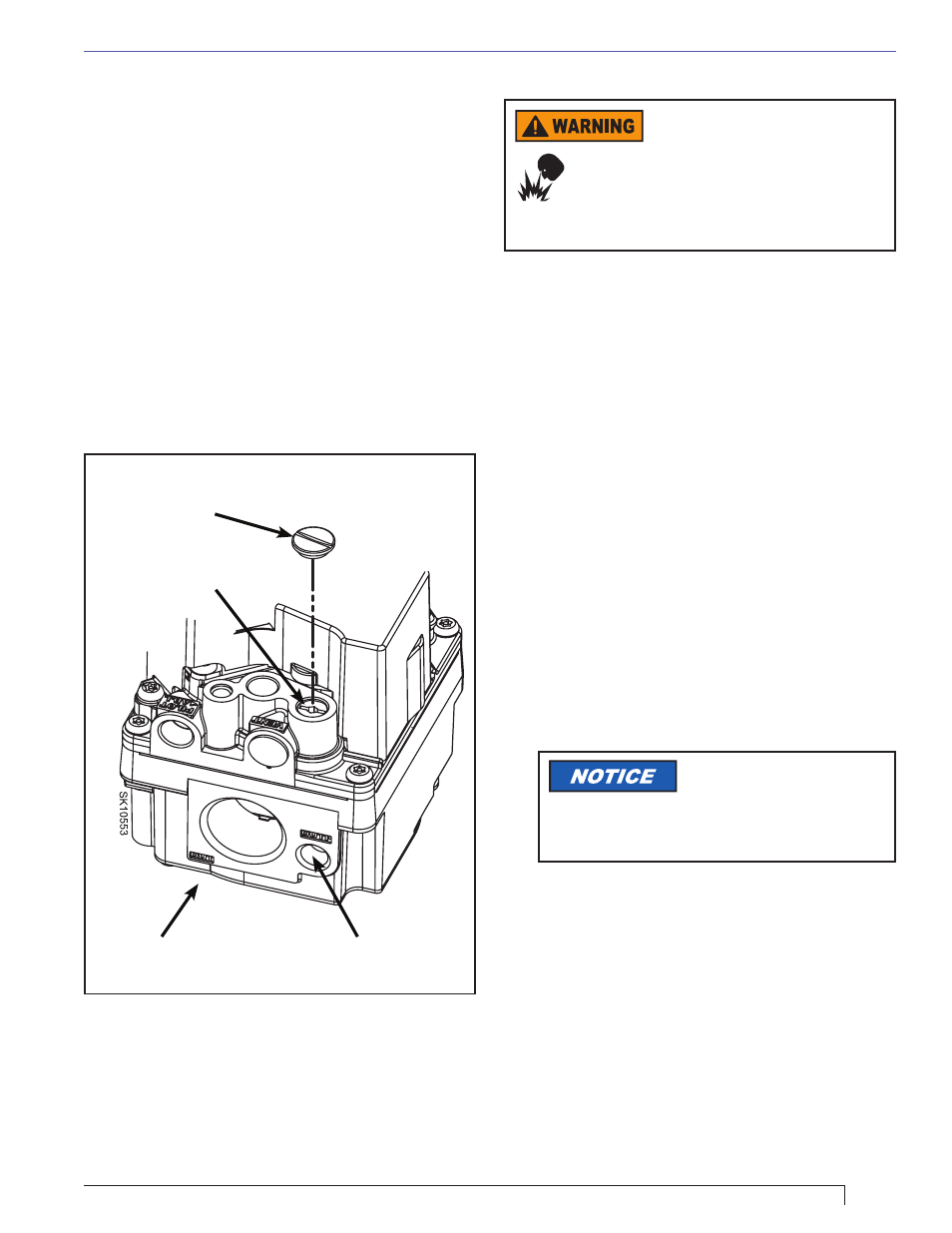

Figure 15 – Gas Valve Pressure Adjustment

Regulator

Cover Screw

Regulator

Adjust Screw

Outlet Pressure Tap

Gas Valve

Check Operation and Safety Controls

Explosion, Fire and

Asphyxiation Hazard

Testing by Qualified Technician Required.

Failure to properly test and verify the

correct function of operation and safety

controls could lead to equipment malfunction and

result in asphyxiation, explosion or fire.

The testing of operating and safety controls requires

technical training and experience with power gas

burners and appliances.

Carefully follow the manufacturer’s instructions supplied

with the appliance and the controls.

Verify the correct function of all operating and safety

controls used in the installation.

If instructions are not available, use the following

recommended procedures and record all results in a

start-up log.

1. High limit/ Pressure Control – To check the High

Limit, raise the temperature or pressure of the

operating control to a higher level and lower the

limit to a setting less than the operating control. Run

the burner until the high limit opens and shuts the

burner off. Adjust the controls back to the desired

settings.

2. Operating control – Run the burner until the

operating control shuts it off. If necessary, make

adjustments to ensure the control cycles the burner

in the desired temperature or pressure range.

Operating controls should

be set to minimize the

number of firing cycles that the burner runs.

High cycling rates increase the possibility of

light-off lock outs.

3. Low water cutoff (LWCO) – With the burner firing,

open the blow down valve on the low water cutoff,

if applicable. As the water level drops, the LWCO

switch contacts open and shut the burner off. When

the water level rises, the LWCO contacts close

and restart the burner. Monitor the LWCO switch

operation in relation to the water level in the sight-

glass for synchronization.