Beckett CG4 User Manual

Page 10

10

Section: INSPECT/PREPARE INSTALLATION SITE

Table 5 – Firing Rates and Configurations

Firing Rate

BTU/Hr.

Fuel Orifices

Air Tube Components

Chassis

Components

Initial Settings

Natural Gas

Orifice Dia.

Inches

L P Orifice

Dia. Inches

Burner

Head

Nozzle

Static Plate

Baffle

Band

Shutter

Band

80,000

0.219

0.166

F3G

01

32910-001

5880

Blank

2-1/2

Blank

90,000

0.234

0.177

F3G

01

32910-001

5880

Blank

4

Blank

100,000

0.25

0.189

F3G

01

32910-001

5880

Blank

5-1/2

Blank

110,000

0.277

0.206

F3G

01

32910-001

5880

Blank

7-1/2

Blank

120,000

0.316

0.219

F3G

01

32910-001

5880

4-slot

9

0

130,000

0.364

0.234

F3G

01

32910-001

n/a

4-slot

5-1/2

0

140,000

N/A

0.242

F3G

01

32910-001

n/a

4-slot

7-1/2

0

130,000

0.281

0.217

F4G

02

32910-001

5880

4-slot

8

0

145,000

0.316

0.234

F4G

02

32910-001

5880

4-slot

10

0

160,000

0.348

0.246

F4G

02

32910-001

n/a

4-slot

6-1/2

0

175,000

0.406

0.261

F4G

02

32910-001

n/a

4-slot

8-1/2

0

190,000

N/A

0.281

F4G

02

32910-001

n/a

4-slot

10

0

180,000

0.332

0.246

F6G

03

n/a

n/a

4-slot

5-1/2

0

190,000

0.354

0.256

F6G

03

n/a

n/a

4-slot

7

0

205,000

0.377

0.266

F6G

03

n/a

n/a

4-slot

8-1/2

0

220,000

0.422

0.281

F6G

03

n/a

n/a

4-slot

10

0

235,000

0.484

0.295

F6G

03

n/a

n/a

4-slot

10

2

250,000

N/A

0.312

F6G

03

n/a

n/a

4-slot

10

4

- Firing rates are based on 3.5” WC manifold gas pressure and use of the appropriate orifice for the fuel being fired.

- Air tube assemblies are provided with a full selection of the natural gas orifices appropriate to the burner head.

- LP orifices are provided in kits containing all the LP orifices for the burner head size. The installer is responsible

for selecting and installing the appropriate orifice for the application.

- Burner heads and nozzles are identified with the markings shown to assure the use of compatible combinations.

- Burner chassis are built for the highest rate configuration. The installer is responsible to add the baffle and/or

change the band as required for the application.

- Initial settings are intended for use only as a starting point for burner adjustments. They can not make provision

for all installation possibilities. It is important that you adjust your burner to your installation requirements using

properly calibrated flue gas analysis instruments.

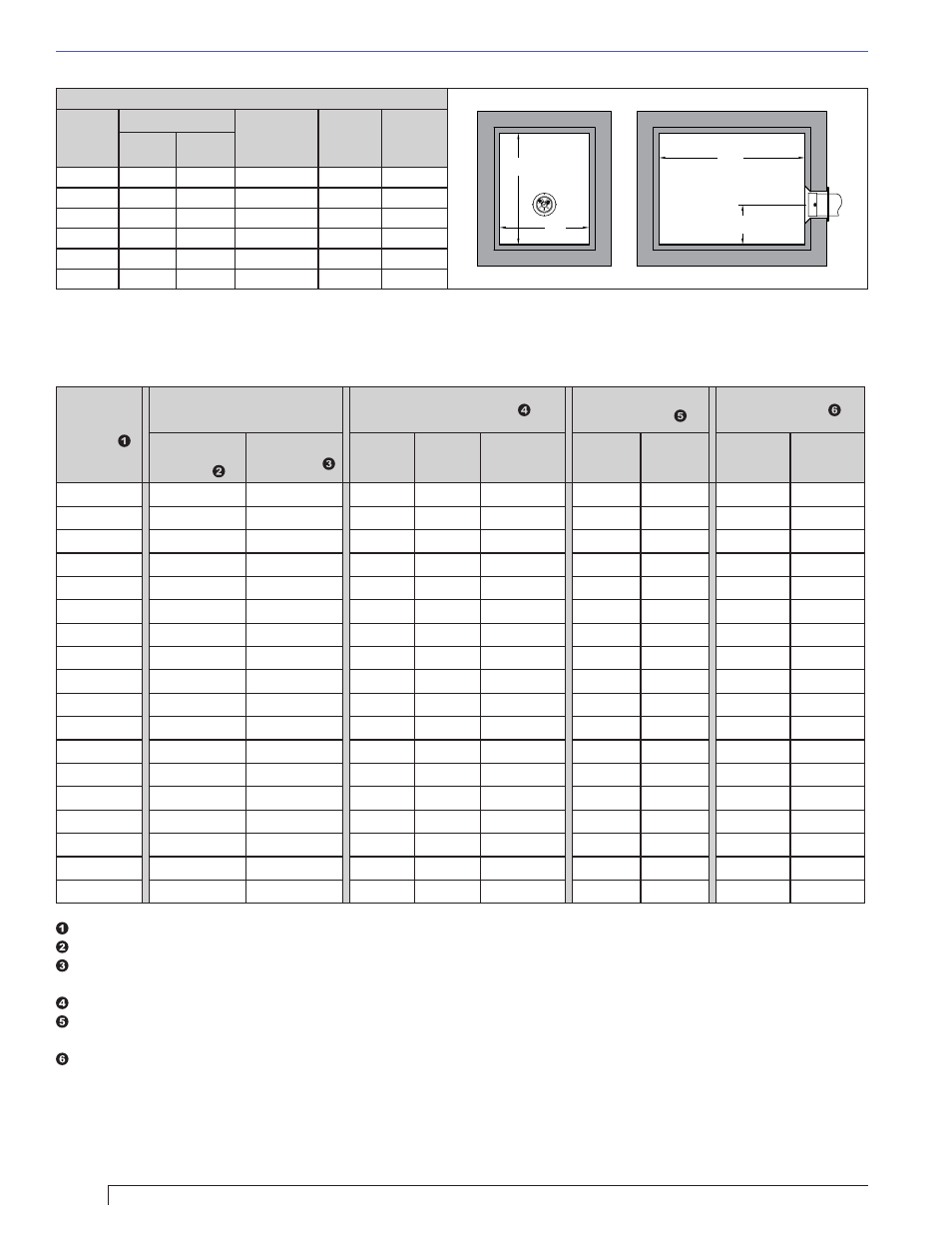

Table 4 – Minimum Combustion Chamber Dims.

Chamber Dimensions (Inches)

H

W

L

A

Firing

Rate

MBH

Rectangular

Horizontal

Cylinder

I. D.

Length

(L)

Floor to

Tube (A)

Width

(W)

Height

(H)

80

8

8

9

13

4

105

9

9

10

13.5

4.5

140

10.5

10.5

12

14

5.3

175

11.5

11.5

13

14.5

5.8

210

13

13

14.5

15

6.5

250

15

15

16

16

7.5