Nexen RPG25A-GE486T 966740 User Manual

Page 16

FORM NO. L-21235-G-0413

16

DISENGAGING THE ROLLER PINION

1. De-couple the load from the RPS system.

2. Disconnect the power source, ensuring that no torque

is applied to the roller pinion.

3. Remove pinion preload by loosening the preload

mechanism sliding bolts slightly and then turning the

preload application screw(s) to remove the pinion

preload. You should be able to slightly separate the

pinion from the rack teeth now.

There are two pinion mounting styles; shaft mount,

and flange mount. Proceed to the following section

that applies to you.

Shaft Mount Pinion Removal

1. Progressively loosen non-adjacent coupling fasteners

in the same order they were tightened until all are

removed from the coupling (Refer to Figure 12).

2. Insert the coupling fasteners into the threaded holes

in the coupling flange and alternately tighten them as

illustrated in Figure 9 to release the locking action of

the coupling.

3. Lift the servo/reducer/preload mechanism assembly

from the rack or slide the servomotor/reducer out of

the pinion bore.

4. Inspect the shaft, and all coupling components and

replace any that show excessive wear if the pinion will

be reinstalled. Contact Nexen for replacements.

Flange Mount Pinion Removal

1. Remove mounting bolts in an alternating cross pattern.

2. Carefully inspect the mounting bolts and pinion and

flange surfaces for any signs of damage and repair or

replace as necessary if reinstalling.

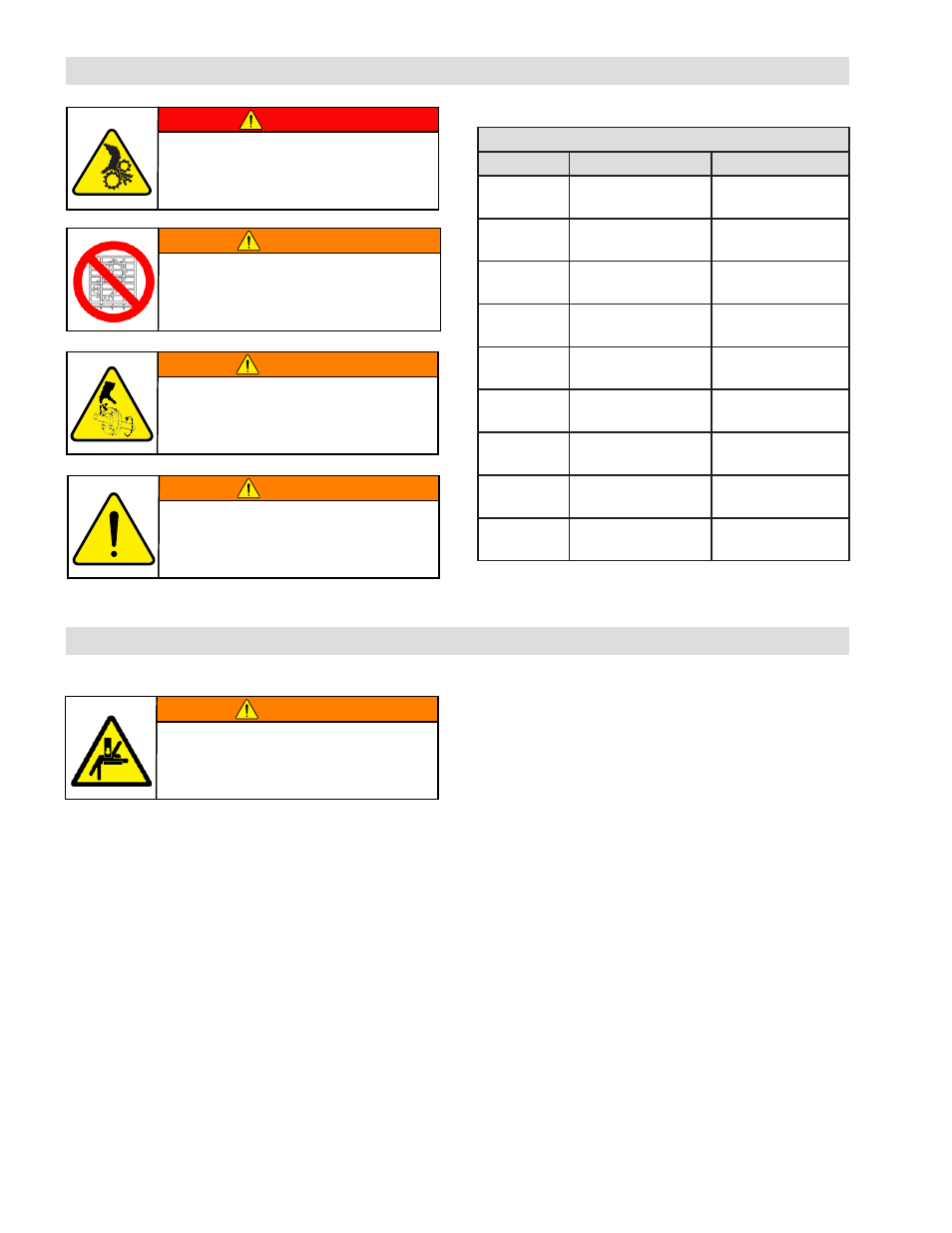

WARNING

Failure to properly support the load

before disengaging the RPS system

could cause serious harm to operators

or equipment.

RPS SYSTEM OPERATION

DANGER

This product has moving parts that

can crush or cut appendages. Provide

adequate spacing or guarding from any

operating product.

WARNING

Use appropriate guarding for rotating

components. Failure to guard could

result in serious bodily injury.

WARNING

Ensure proper guarding of the product is

used. Nexen recommends the machine builder

design guarding in compliance with OSHA 29

CFR 1910 “Occupational Safety and Health

Hazards”.

WARNING

Never exceed maximum operating speeds

listed for your product. (See Table 7).

TABLE 7

RPS Maximum Speeds*

Product

Linear Speed

Pinion RPM

RPS10

4 m/s

[13.1 ft/s]

2400

RPS12

8 m/s

[26.3 ft/s]

4000

RPS16

4 m/s

[13.1 ft/s]

1500

RPS20

5 m/s

[16.4 ft/s]

1500

RPS25

8 m/s

[26.2 ft/s]

1920

RPS32

11 m/s

[36.1 ft/s]

1719

RPS40

6 m/s

[19.7 ft/s]

750

RPS4014

6 m/s

[19.7 ft/s]

643

RPS50

6 m/s

[19.7 ft/s]

600

* Standard RPS speed ratings, specials can vary. Review

Nexen specifications for your specific product number.

- RPG20A-GE180T 966734 RPG20A-GE140T 966706 RPG32A-GE0450T 966685 RPG16A-GE400T 966656 RPG20A-GE150T 966615 RPG16A-GE150T 966557 RPG16A-GE936T 966556 RPG4014A-GE192T 966548 RPG4014A-GE072T 966547 RPS25 966679 RPS25 966678 RPS20 966707 RPG32A-GE0760T 966779 ISO9409-064-SS 960855 ISO9409-090 960850 ISO9409-064 960851 ISO9409-200 960854 ISO9409-140 960853 ISO9409-110 960852 RPS40 966543 RPS32 966533 RPS25 966523 RPS20 966513 RPS12 966508 RPS10 966507 RPS16 966503 RPS20 966618 RPS16 966715 RPS16 966687 RPS32 966677 RPS40 966697 RPS4014 966700 RPS25 966673 RPS20 966753 RPS20 966675 RPS20 966781 RPS16 966650 RPS32 966680 RPS4014 966693 RPS40 966690 RPS25 966670 RPS20 966660 RPS16 966850 RPS32 966853 RPS25 966852 RPS4014 966855 RPS40 966854 RPS20 966851 RPS16 966605 RPS16 966606 RPS16 966651 RPS32 966681 RPS16 966654 RPS32 966608 RPS4014 966695 RPS40 966692 RPS16 966652 RPS32 966682 RPS25 966672 RPS20 966662 RPS12 966769 RPS10 966768 RPS16 966777 RPS32 966609 RPS16 966709 RPS25 966671 RPS4014 966694 RPS40 966691 RPS20 966661 RPS16 966800 RPS32 966806 RPS4014 966811 RPS40 966809 RPS16 966801 RPS32 966807 RPS25 966805 RPS20 966803 RPS25 966804 RPS40 966810 RPS40 966808 RPS20 966802 RPS16 966741 RPS16 966742 RPS25 966755 RPS20 966619 RPS4014 966601 RPS40 966631 RPS4014 966647 RPS32 966642 RPS16 966602 RPS32 966632 RPS25 966622 RPS20 966612 RPS25 966621 RPS4014 966646 RPS40 966641 RPS20 966611