Nexen RPG25A-GE486T 966740 User Manual

Page 12

FORM NO. L-21235-G-0413

12

Table 3 Pinion Coupling Bolt Information

Model

Bolt Size

Tightening Torque

RPS10

M3

1.9 Nm [16.8 in-lb]

RPS12

M4

4.1 Nm [36.3 in-lb]

RPS16

M4

3.5 Nm [31.0 in-lb]

RPS20

M5

7.0 Nm [62.0 in-lb]

RPS 25, 32, 40

M6

12.0 Nm [106.2 in-lb]

RPS4014

M8

38.0 Nm [336.3 in-lb]

RPS50

M10

54.9 Nm [485.9 in-lb]

Flange Mount Pinion Installation (ISO 9409)

1. Clean the gearhead mounting face and pilot bore

inspecting for contaminates, burs, or surface defects

that would interfere with full contact between the

pinion and flange or cause runout.

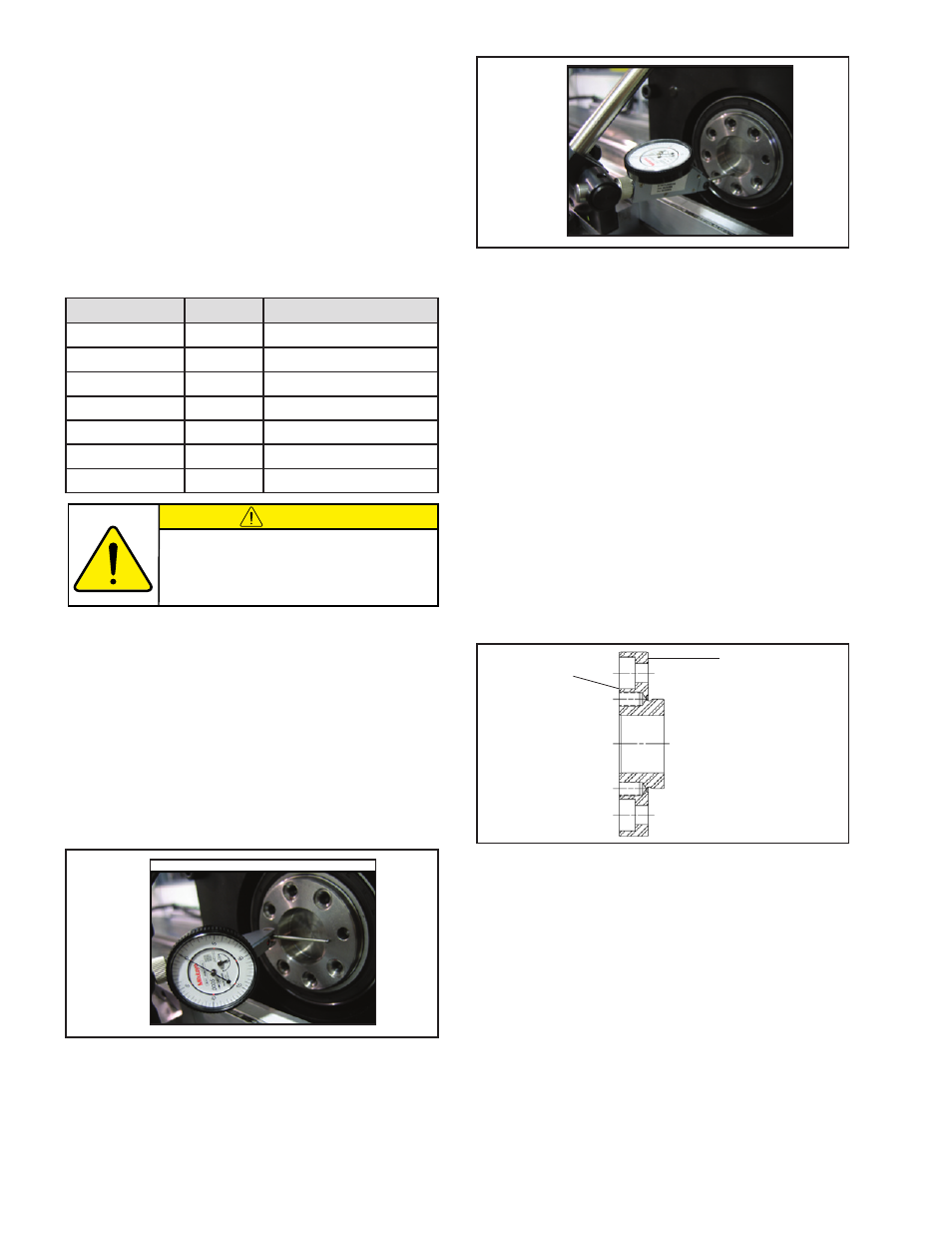

2. Using a dial indicator, check the rotational flatness of

the face as shown in Figure 13. Position the contact

point of the indicator where the pinion will contact

it. Rotate slowly for a minimum of one complete

revolution and note the total amount of runout.

Figure 15

3. Position the contact point of the dial indicator at

bottom dead center of the pilot bore as shown in

Figure 14. Rotate slowly for a minimum of one

complete turn and note the amount of total runout in

one rotation.

10. Once the fasteners are fully torqued verify the pinion

is centered on the rack. If not, measure the positional

error and then remove the pinion as described in the

DISENGAGING THE ROLLER PINION section.

Repeat the pinion installation procedure and offset the

pinion by the recorded error plus the previous off set

value. When the pinion is fully torqued and properly

centered on the rack then verify pinion concentricity

at the center of the pinion rollers as shown in Figure

11. Indicated concentric runout on this surface must

be less than ± 0.030 mm [±0.0010 in].

4. If either of the following conditions are true, the

gearhead itself may contribute to excessive pinion

preload variation, a reduction in pinion life and/

or accuracy. The user should consider having the

gearhead re-worked or replaced.

a. The measured total variance of the mounting face

is greater than 0.013 mm [0.0005 in].

b. The measured total variance of the pilot bore wall

is greater than 0.005 mm [0.0002 in].

Note: In some cases an adapter will be required to

mount the pinion on the reducer. If so proceed with

Step 5, if not skip to Step 13.

5. Clean the adapter flange and pilot where it will contact

the gearhead flange inspecting for contaminates,

burs, or surface defects that would interfere with full

contact between the adapter and gearhead flange.

See Figure 15.

6. Apply a serviceable thread locking compound to the

adapter mounting screws then assemble the adapter

to the gearhead, leaving the mounting screws snug

but do not tighten at this time as shown in Figure 16.

7. Position a dial indicator at bottom dead center of the

pilot bore wall as shown in Figure 16 and zero the

indicator. Rotate the assembly slowly by using the

gearhead input shaft a minimum of one complete

revolution while noting the dial indicator runout and

mark the angular location in which the lowest reading

occurs throughout the rotation.

Figure 13

Figure 14

Pinion Side

Gearhead

Side

CAUTION

Preload must be applied before putting your

system into operation. Refer to APPLYING

PRELOAD to properly set preload for your

RPS system.

- RPG20A-GE180T 966734 RPG20A-GE140T 966706 RPG32A-GE0450T 966685 RPG16A-GE400T 966656 RPG20A-GE150T 966615 RPG16A-GE150T 966557 RPG16A-GE936T 966556 RPG4014A-GE192T 966548 RPG4014A-GE072T 966547 RPS25 966679 RPS25 966678 RPS20 966707 RPG32A-GE0760T 966779 ISO9409-064-SS 960855 ISO9409-090 960850 ISO9409-064 960851 ISO9409-200 960854 ISO9409-140 960853 ISO9409-110 960852 RPS40 966543 RPS32 966533 RPS25 966523 RPS20 966513 RPS12 966508 RPS10 966507 RPS16 966503 RPS20 966618 RPS16 966715 RPS16 966687 RPS32 966677 RPS40 966697 RPS4014 966700 RPS25 966673 RPS20 966753 RPS20 966675 RPS20 966781 RPS16 966650 RPS32 966680 RPS4014 966693 RPS40 966690 RPS25 966670 RPS20 966660 RPS16 966850 RPS32 966853 RPS25 966852 RPS4014 966855 RPS40 966854 RPS20 966851 RPS16 966605 RPS16 966606 RPS16 966651 RPS32 966681 RPS16 966654 RPS32 966608 RPS4014 966695 RPS40 966692 RPS16 966652 RPS32 966682 RPS25 966672 RPS20 966662 RPS12 966769 RPS10 966768 RPS16 966777 RPS32 966609 RPS16 966709 RPS25 966671 RPS4014 966694 RPS40 966691 RPS20 966661 RPS16 966800 RPS32 966806 RPS4014 966811 RPS40 966809 RPS16 966801 RPS32 966807 RPS25 966805 RPS20 966803 RPS25 966804 RPS40 966810 RPS40 966808 RPS20 966802 RPS16 966741 RPS16 966742 RPS25 966755 RPS20 966619 RPS4014 966601 RPS40 966631 RPS4014 966647 RPS32 966642 RPS16 966602 RPS32 966632 RPS25 966622 RPS20 966612 RPS25 966621 RPS4014 966646 RPS40 966641 RPS20 966611