Nexen PRD1500 966903 User Manual

Linear motion control products, Precision ring drive with removable pinion

Precision Ring Drive with Removable Pinion

Precision Ring Drives containing the removable pinion option should follow this document

for servicing of the pinion and setting preload. For all other installation instructions, refer to

Nexen literature 21265.

LINEAR MOTION CONTROL PRODUCTS

Install & Maintenance Supplement

1

PINION REPLACEMENT AND PRELOAD

Installation:

1. Clean the gearhead mounting face and pilot bore

inspecting for contaminates, burs, or surface defects.

2. Check the runout of the gearbox pilot bore and face.

Both items should be less than 0.008 mm.

3. Clean the pinion flange and pilot where it will contact

the gearbox.

4. Apply serviceable thread locking compound to the

pinion mounting screws and install the pinion.

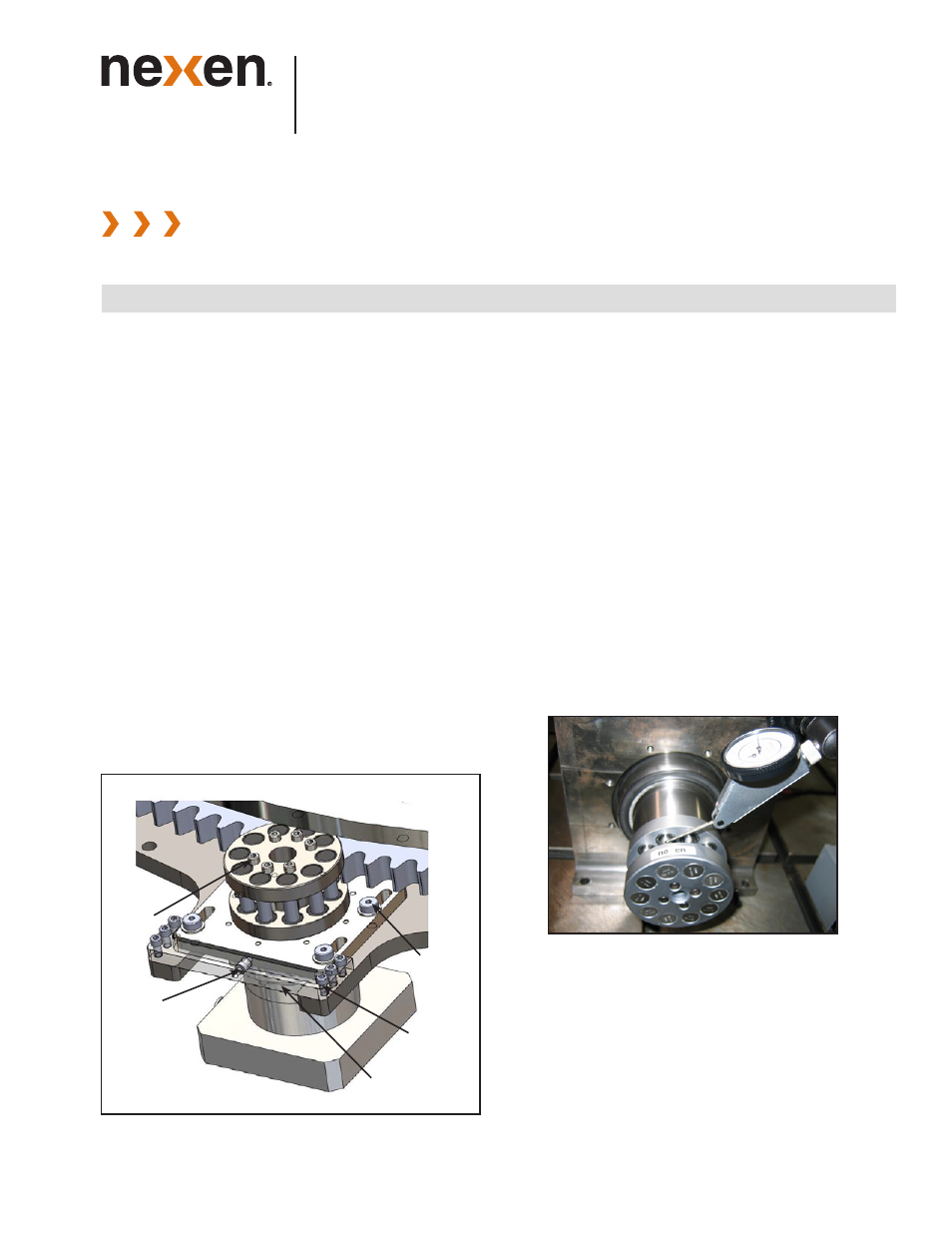

5. Position dial indicator on the center of the pinion rollers

as shown in Figure 2 and zero it. Rotate the pinion a

minimum of one complete revolution noting the runout

on the top of each pin. When the pinion is properly

centered the concentric runout at the center of the

rollers must be less than +/- 0.030 mm.

6. Tighten the mounting screws to 8.5 Nm in a star pattern.

Then repeat the tightening pattern to 17.5 Nm. Check

pinion runout one more time to ensure it did not move

during tightening.

7. Slide pinion/preloader gearbox setup into contact with

the gear, do not force them together, preload will be

set in the upcoming steps.

Figure 2

The PRD is delivered with the proper preload from the

factory. If pinion service is required, the following will guide

you through the process of pinion replacement and preload.

Removal:

1. To replace pinion, loosen, do not remove, the four

preload screws (Item 1) as shown in Figure 1. Leave

the screws just loose enough so the plate will slide.

2. Remove preload by turning the preload bolt (Item 2)

clockwise as shown in Figure 1. The screw is only for

pushing the pinion into gear, turning screw clockwise

will not pull the pinion from the gear, it only removes

the system tension. Turn screw until it bottoms out.

3. Remove the six screws (Item 3) to remove the preload

adjust plate (Item 4).

4. Slide the preload plate/pinion/gearbox assembly out

of tooth mesh.

5. To remove the pinion, remove the six screws (Item 5).

Figure 1

Item 2

Item 1

Item 4

Item 3

Item 5