48h e, h j – Carrier 48HJ004---007 User Manual

Page 55

55

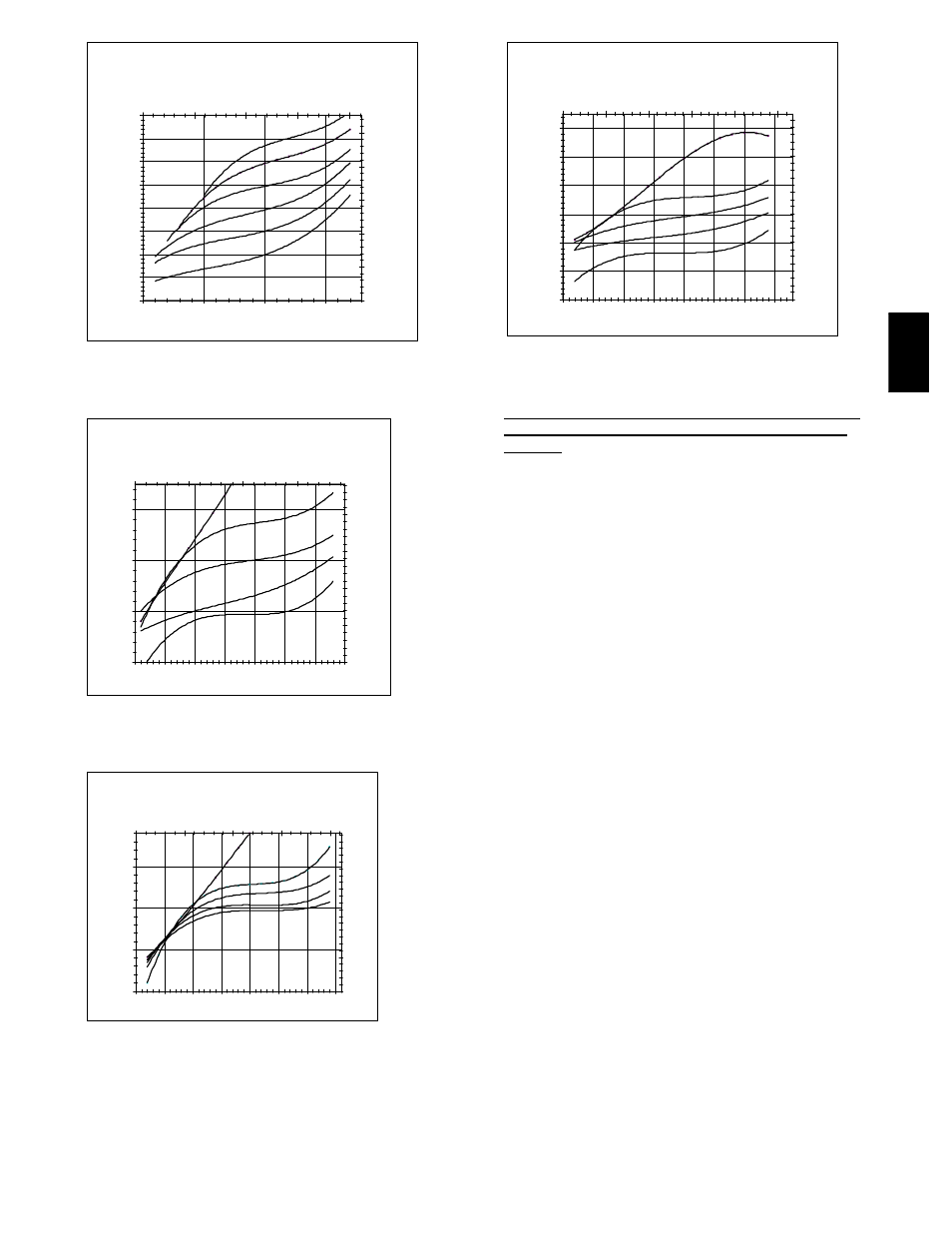

48HE -- 2 TON CHARGING CHART

65.0

70.0

75.0

80.0

85.0

90.0

95.0

100.0

105.0

42

52

62

72

Suction Line Temp (deg F)

S

ucti

on

Li

ne

P

ressu

re

(p

si

g)

448.0

498.0

548.0

598.0

648.0

698.0

5.5

10.5

15.5

20.5

25.5

Suction Line Temperature (deg C)

S

ucti

on

Li

ne

P

ressu

re

(kp

a)

F

C

125

52

115

46

105

41

95

35

85

29

75

24

C06148

Fig. 68

--- Cooling Charging Chart,

Standard 48HE003

48HE -- 3 TON CHARGING CHART

65.0

75.0

85.0

95.0

43

48

53

58

63

68

73

78

Suction Line Temp (deg F)

S

uc

tio

n

Lin

e

P

re

ss

ur

e

(p

sig

)

448.2

498.2

548.2

598.2

648.2

6.1

11.1

16.1

21.1

Suction Line Temperature (deg C)

S

uc

tio

n

Lin

e

P

re

ss

ur

e

(k

pa

)

F

C

115

46

105

41

95

35

85

29

75

24

C06149

Fig. 69

--- Cooling Charging Chart,

Standard 48HE004

48HE -- 4 TON CHARGING CHART

67.0

77.0

87.0

97.0

42

47

52

57

62

67

72

77

Suction Line Temp (deg F)

Suction

L

ine

Pressure

(psig)

492.0

542.0

592.0

642.0

692.0

5.6

10.6

15.6

20.6

25.6

Suction Line Temperature (deg C)

Suction

L

ine

Pressure

(kpa)

F

C

115

46

105

41

95

35

85

29

75

24

C06150

Fig. 70

--- Cooling Charging Chart,

Standard 48HE005

48HE -- 5 TON CHARGING CHART

55.0

65.0

75.0

85.0

95.0

105.0

115.0

42

47

52

57

62

67

72

77

Suction Line Temp (deg F)

S

ucti

on

Li

ne

P

ressu

re

(p

si

g)

310.0

410.0

510.0

610.0

710.0

810.0

0.0

5.0

10.0

15.0

20.0

25.0

Suction Line Temperature (deg C)

S

ucti

on

Li

ne

P

ressu

re

(kp

a)

F

C

115

46

105

41

95

35

85

29

75

24

C06151

Fig. 71

--- Cooling Charging Chart,

Standard 48HE006

TO USE COOLING CHARGING CHARTS, UNITS WITH

HUMIDI--MIZER™ ADAPTIVE DEHUMIDIFICATION

SYSTEM

Refer to charts (Fig. 64-67) to determine the proper leaving

condenser pressure and temperature.

Example (Fig. 64):

Leaving Condenser Pressure

250 psig

. . . . . . . . . . . . . . . . .

Leaving Condenser Temperature

105°F

. . . . . . . . . . . . . . .

NOTE: When using the charging charts, it is important that only

the subcooling/reheat dehumidification coil liquid line solenoid

valve be energized. The subcooling/reheat dehumidification coil

liquid line solenoid valve MUST be energized to use the charging

charts and the outdoor motor speed controller jumpered to run the

fan at full speed.

Step 10

—Flue Gas Passageways

To inspect the flue collector box and upper areas of the heat

exchanger:

1. Remove the combustion blower wheel and motor

assembly according to directions in Combustion-Air

Blower section below.

2. Remove the 3 screws holding the blower housing to the

flue cover.

3. Remove the flue cover to inspect the heat exchanger.

4. Clean all surfaces as required using a wire brush.

Step 11

—Combustion--Air Blower

Clean periodically to ensure proper airflow and heating

efficiency. Inspect blower wheel every fall and periodically

during heating season. For the first heating season, inspect blower

wheel bimonthly to determine proper cleaning frequency.

To inspect blower wheel, remove draft hood and screen. Shine a

flashlight into opening to inspect wheel. If cleaning is required,

remove motor and wheel as follows:

1. Slide burner access panel out.

2. Remove the 5 screws that attach induced-draft motor

assembly to the vestibule cover.

3. Slide the motor and blower wheel assembly out of the

blower housing. The blower wheel can be cleaned at this

point. If additional cleaning is required, continue with

Steps 4 and 5.

4. To remove blower from the motor shaft, remove

2 setscrews.

5. To remove motor, remove the 4 screws that hold the

motor to mounting plate. Remove the motor cooling fan

48H

E,

H

J