48h e, h j – Carrier 48HJ004---007 User Manual

Page 12

12

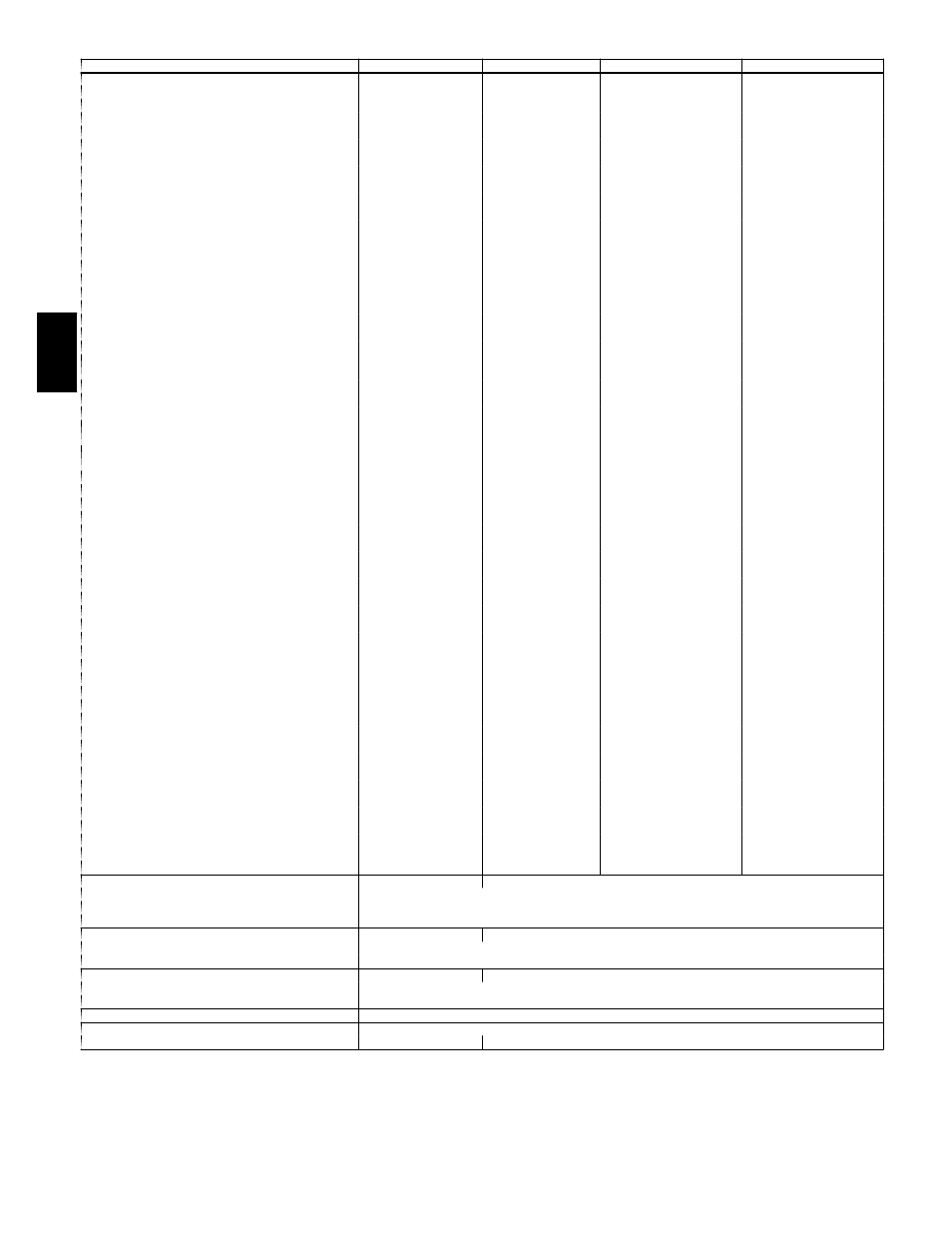

TABLE 2 — PHYSICAL DATA 48HE (cont)

BASE UNIT 48HE

HD/E/F003

HE/F/H/K/M/N004

HD/E/F/G/H/K/L/M/N005

HD/E/F/G/H/K/L/M/N006

FURNACE SECTION

Rollout Switch Cutout Temp (F)†

195

195

195

195

Burner Orifice Diameter (in. ...drill size)**

Natural Gas — Std*

HJE .113...33

HJD .113...33

HJD .113...33

HEE .089...43

HJF .113...33

HJE .113...33

HJE .113...33

—

HJF .129...30

HJF .129...30

—

HJH .113...33

HJG .113...33

HJG .113...33

—

HJK .113...33

HJH .113...33

HJH .113...33

—

—

HJK .129...30

HJK .129...30

HEM .089...43

HJM .102...38

HJL .102...38

HJL .102...38

—

HJN .102...38

HJM .102...38

HJM .102...38

—

—

HJN .116...32

HJN .116...32

Liquid Propane — Alt††

HEE .073...49

HJE .089...43

HJD .089...43

HJD .089...43

HJF .089...43

HJE .089...43

HJE .089...43

—

HJF .104...37

HJF .104...37

—

HJH .089...43

HJG .089...43

HJG .089...43

—

HJK .089...43

HJH .089...43

HJH .089...43

—

—

HJK .102...37

HJK .104...37

—

—

—

—

Thermostat Heat Anticipator Setting (amps)

208/230/460/575 v

First Stage

.14

.14

.14

.14

Second Stage

.14

.14

.14

.14

Gas Input (Btuh)

First Stage/Second Stage

HEE 50,000/---

HEE||

50,000/ 72,000

HED|| 50,000/ 72,000

HED|| 50,000/ 72,000

HEF||

82,000/115,000

HEE|| 82,000/115,000

HEE|| 82,000/115,000

—

HEF|| 120,000/150,000

HEF|| 120,000/150,000

—

HEH*** —/ 72,000

HEG*** —/ 72,000

HEG*** —/ 72,000

—

HJK***—/115,000

HEH*** —/115,000

HEH*** —/115,000

—

—

HEK*** —/150,000

HEK*** —/150,000

—

HEM††† —/ 60,000

HEL††† —/ 60,000

HEL††† —/ 60,000

—

HEN††† —/ 90,000

HEM††† —/ 90,000

HEM†††—/ 90,000

—

—

HEN††† —/120,000

HEN††† —/120,000

Efficiency (Steady State) (%)

HEE 81

HEE 82.8

HED 82.8

HED 82.8

HEF 80

HEE 81

HEE 81

—

HEF 80.4

HEF 80.4

—

HEH 82

HEG 82

HEG 82

—

HEK 80

HEH 81

HEH 81

—

—

HEK 80

HEK 80

—

HEM 80.2

HEL 80.2

HEL 80.2

HEM 81

HEN 81

HEM 81

HEM 81

—

—

HEN 80.7

HEN 80.7

Temperature Rise Range

HEE 25-55

HED 25-25

HED 25-55

HEE 25-65

HEF 55-85

HEE 35-65

HEE 35-65

—

HEF 50-80

HEF 50-80

—

HEH 25-55

HEG 25-55

HEG 25-55

—

HEK 55-85

HEH 35-65

HEH 35-65

—

—

HEK 50-80

HEK 50-80

—

HEM 20-50

HEL 20-50

HEL 20-50

—

HEN 30-60

HEM 30-60

HEM 30-60

—

—

HEN 40-70

HEN 40-70

Manifold Pressure (in. wg)

Natural Gas — Std

3.5

3.5

3.5

3.5

Liquid Propane — Alt††

3.5

3.5

3.5

3.5

Maximum Static Pressure (in. wg)

1.0

1.0

1.0

1.0

Field Gas Connection Size (in.)

1

/

2

1

/

2

1

/

2

1

/

2

HIGH-PRESSURE SWITCH (psig)

Standard Compressor Internal Relief

450 ± 50

Cutout

428

Reset (Auto.)

320

LOSS-OF-CHARGE SWITCH (Liquid LIne) (psig)

Cutout

7 ± 3

Reset (Auto.)

22 ± 5

FREEZE PROTECTION THERMOSTAT

Opens (F)

30 ± 5

Closes (F)

45 ± 5

OUTDOOR-AIR INLET SCREENS

Cleanable. Screen quantity and size varies with option selected.

RETURN-AIR FILTERS

Throwaway

Quantity...Size (in.)

2...16 x 25 x 2

LEGEND

Bhp — Brake Horsepower

*Stainless steel models use same orifices as equivalent standard unit.

†Indicates automatic reset.

**≤72,000 Btuh heat input units have 2 burners. 90,000 and

120,000 Btuh heat

input units have 3 burners. 115,000 Btuh heat input units and 150,000 Btuh Heat

input units have 3 burners.

††An LP kit is available as an accessory. An LP conversion kit should not be used on a

low NOx unit because then it can no longer be classified as a Low NOx unit. The

Low NOx requirement only applies to natural gas units.

Three-phase standard models have heating inputs as shown. Single-phase standard

models have one-stage heating with heating input values as shown in heatin capac-

ity tables.

***These units do NOT meet the California low NOx requirements.

†††California SCAQMD compliant low NO

x

models have combustion products that are

controlled to 40 nanograms per joule or less.

48H

E,

H

J