Carrier 48HJ004---007 User Manual

Page 49

49

S

SPT reading is available

S

OAT ± SPT

S

Economizer Position is NOT forced

If any of the above conditions are not met, the economizer

submaster reference (ECSR) is set to maximum limit and the

damper moves to minimum position. The operating sequence is

complete. The ECSR is recalculated every 30 seconds.

If an optional power exhaust is installed, as the outdoor-air

damper opens and closes, the power exhaust fans will be

energized and deenergized.

If field-installed accessory CO

2

sensors are connected to the

PremierLink™ control, a PID-controlled demand ventilation

strategy will begin to operate. As the CO

2

level in the zone

increases above the CO

2

set point, the minimum position of the

damper will be increased proportionally. As the CO

2

level

decreases because of the increase in fresh air, the outdoor-air

damper will be proportionally closed.

HEATING -- UNIT WITH ECONOMI$ER2, PREMIER-

LINK CONTROL AND A ROOM SENSOR

Every 40 seconds the controller will calculate the required heat

stages (maximum of 3) to maintain Supply-Air Temperature

(SAT) if the following qualifying conditions are met:

S

Indoor fan has been on for at least 30 seconds.

S

COOL mode is not active.

S

OCCUPIED, TEMP. COMPENSATED START or

HEAT mode is active.

S

SAT reading is available.

S

Fire shutdown mode is not active.

If all of the above conditions are met, the number of heat stages is

calculated; otherwise the required number of heat stages will be

set to 0.

If the PremierLink controller determines that heat stages are

required, the economizer damper will be moved to minimum

position if occupied and closed if unoccupied.

Staging should be as follows:

If Heating PID STAGES=2

S

HEAT STAGES=1 (50% capacity) will energize HS1

S

HEAT STAGES=2 (100% capacity) will energize HS2

If Heating PID STAGES=3 and AUXOUT = HS3

S

HEAT STAGES=1 (33% capacity) will energize HS1

S

HEAT STAGES=2 (66% capacity) will energize HS2

S

HEAT STAGES=3 (100% capacity) will energize HS3

In order to prevent short cycling, the unit is locked into the

Heating mode for at least 10 minutes when HS1 is deenergized.

When HS1 is energized the induced-draft motor is then

energized and the burner ignition sequence begins. On units

equipped for two stages of heat, when additional heat is needed,

HS2 is energized and the high-fire solenoid on the main gas valve

(MGV) is energized. When the space condition is satisfied and

HS1 is deenergized the IFM stops after a 45-second time-off

delay unless in the occupied mode. The fan will run continuously

in the occupied mode as required by national energy and fresh air

standards.

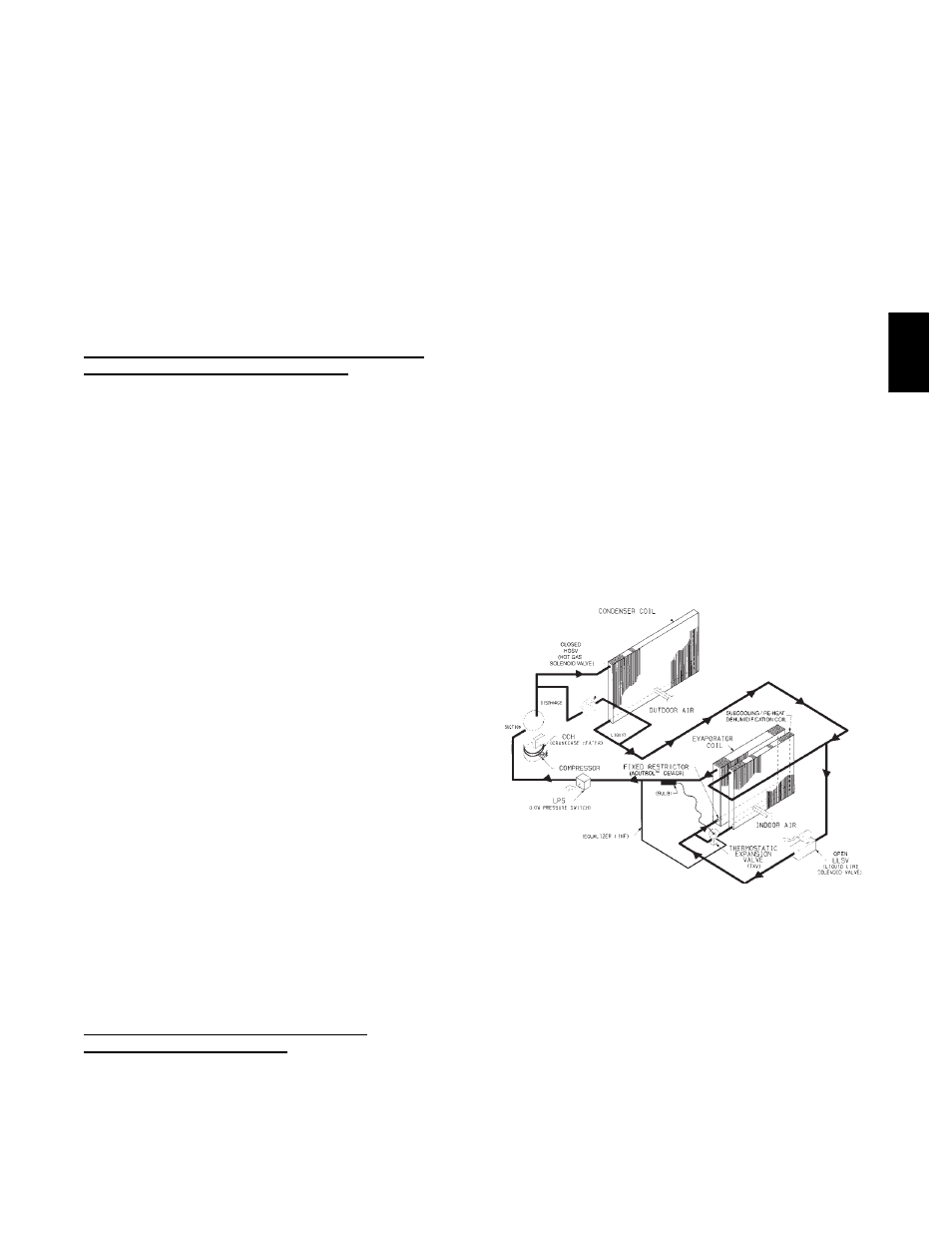

UNITS WITH HUMIDI-MIZER™ ADAPTIVE

DEHUMIDIFICATION SYSTEM

Normal Design Operation

When the rooftop operates under the normal sequence of

operation, the compressors will cycle to maintain indoor

conditions. (See Fig. 53.)

The Humidi-MiZer adaptive dehumidification system includes a

factory-installed Motormaster® low ambient control to keep the

head and suction pressure high, allowing normal design cooling

mode operation down to 0° F.

Subcooling Mode

When subcooling mode is initiated, this will energize (close) the

liquid line solenoid valve (LLSV) forcing the hot liquid

refrigerant to enter into the subcooling coil. (See Fig. 54.)

As the hot liquid refrigerant passes through the subcooling/ reheat

dehumidification coil, it is exposed to the cold supply airflow

coming through the evaporator coil. The liquid is further

subcooled to a temperature approaching the evaporator

leaving-air temperature. The liquid then enters a thermostatic

expansion valve (TXV) where the liquid drops to a lower

pressure. The TXV does not have a pressure drop great enough to

change the liquid to a 2-phase fluid, so the liquid then enters the

Acutrol™ device at the evaporator coil.

The liquid enters the evaporator coil at a temperature lower than

in standard cooling operation. This lower temperature increases

the latent capacity of the rooftop unit. The refrigerant passes

through the evaporator and is turned into a vapor. The air passing

over the evaporator coil will become colder than during normal

operation. However, as this same air passes over the subcooling

coil, it will be slightly warmed, partially reheating the air.

Subcooling mode operates only when the outside air

temperature is warmer than 40_F. A factory-installed temperature

switch located in the condenser section will lock out subcooling

mode when the outside temperature is cooler than 40_F.

The scroll compressors are equipped with crankcase heaters to

provide protection for the compressors due to the additional

refrigerant charge required by the subcooling/reheat coil.

When in subcooling mode, there is a slight decrease in system

total gross capacity (5% less), a lower gross sensible capacity

(20% less), and a greatly increased latent capacity (up to 40%

more).

C06135

Fig. 53

--- Humidi--MiZer Normal

Design Cooling Operation

48H

E,

H

J