Carrier 48HJ004---007 User Manual

Page 51

51

Table 39—Humidi-Mizer Adaptive Dehumidification System Sequence of Operation and

System Response — Single Compressor Unit (48HE003--006, 48HJ004-007)

THERMOSTAT INPUT

ECONOMIZER FUNCTION

48HE, HJ UNIT OPERATION

H

Y1

Y2

OAT. < Economizer Set Point

Economizer

Comp. 1

Subcooling Mode

Hot Gas Reheat Mode

Off

—

—

Normal Operation

On

On

On

No

Off

On

Yes

No

On

On

Off

No

Off

On

Yes

No

On

On

On

Yes

On

On

Yes

No

On

On

Off

Yes

On

On

No

Yes

On

Off

Off

No

Off

On

No

Yes

NOTE: On a thermostat call for W1, all cooling and dehumidification will be off.

LEGEND

OAT --- Outdoor Air Temperature

C06045

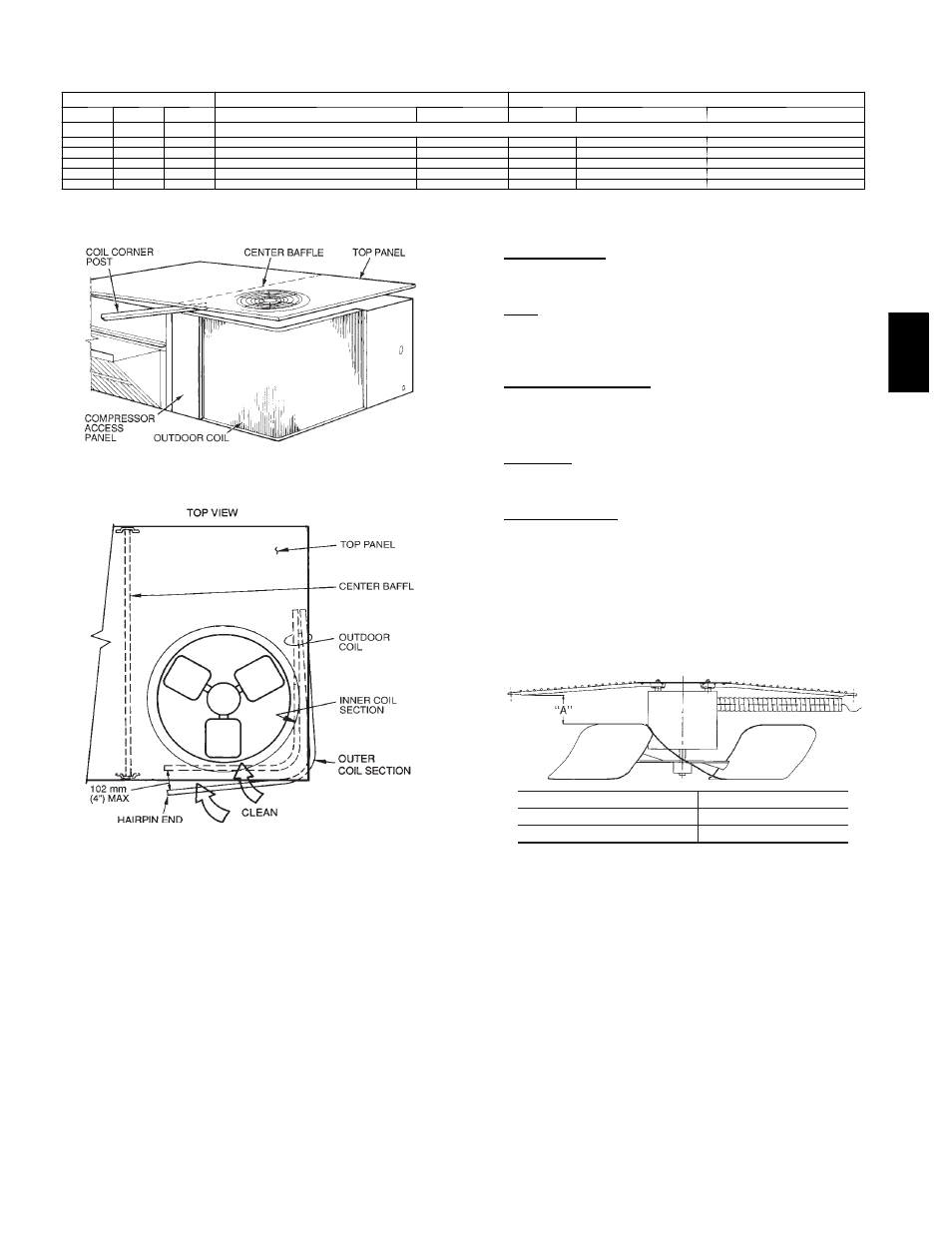

Fig. 57

--- Propping Up Top Panel

C06046

Fig. 58

--- Separating Coil Sections

4. Remove screws securing coil to compressor plate and

compressor access panel.

5. Remove fastener holding coil sections together at return

end of condenser coil. Carefully separate the outer coil

section 3 to 4 in. from the inner coil section. (See Fig. 58.)

6. Use a water hose or other suitable equipment to flush

down between the 2 coil sections to remove dirt and

debris. Clean the outer surfaces with a stiff brush in the

normal manner.

7. Secure inner and outer coil rows together with a

field-supplied fastener.

8. Reposition the outer coil section and remove the coil

corner post from between the top panel and center post.

Reinstall the coil corner post and replace all screws.

condensate drain

Check and clean each year at the start of the cooling season. In

winter, keep the drain dry or protect it against freeze-up.

filters

Clean or replace at the start of each heating and cooling season, or

more often if operating conditions require it. Replacement filters

must be the same dimensions as the original filters.

outdoor--air inlet screens

Clean the screens with steam or hot water and a mild detergent.

Do not use disposable filters in place of screens.

Step 2

—Lubrication

compressor

The compressor is charged with the correct amount of oil at the

factory.

fan motor bearings

Fan motor bearings are permanently lubricated. No further

lubrication is required.

No lubrication of condenser-fan or

evaporator-fan motors is required.

Step 3

—Condenser--Fan Adjustment

Shut off unit power supply. Remove condenser-fan assembly

(grille, motor, motor cover, and fan) and loosen fan hub

setscrews. Adjust fan height as shown in Fig. 59. Tighten

setscrews and replace condenser-fan assembly.

UNIT

FAN HEIGHT (in.) — “A”

003-006 AND 007 (208/230 v)

2.75

007 (460 v)

3.50

C06138

Fig. 59

--- Condenser--Fan Adjustment

Step 4

—EconoMi$er IV Adjustment

Refer to Optional EconoMi$er IV and EconoMi$er2 section.

Step 5

—Evaporator Fan Belt Inspection

Check con-dition of evaporator belt or tension during heating and

cooling inspections or as conditions require. Replace belt or

adjust as necessary.

Step 6

—High Pressure Switch

The high-pressure switch contains a Schrader core depressor, and

is located on the compressor hot gas line. This switch opens at

428 psig and closes at 320 psig. No adjustments are necessary.

48H

E,

H

J