2 vetter mini test sealing bags 2.5 bar, Description, Technical data – Vetter Pipe and Test Sealing Bags User Manual

Page 17

Page 17/33

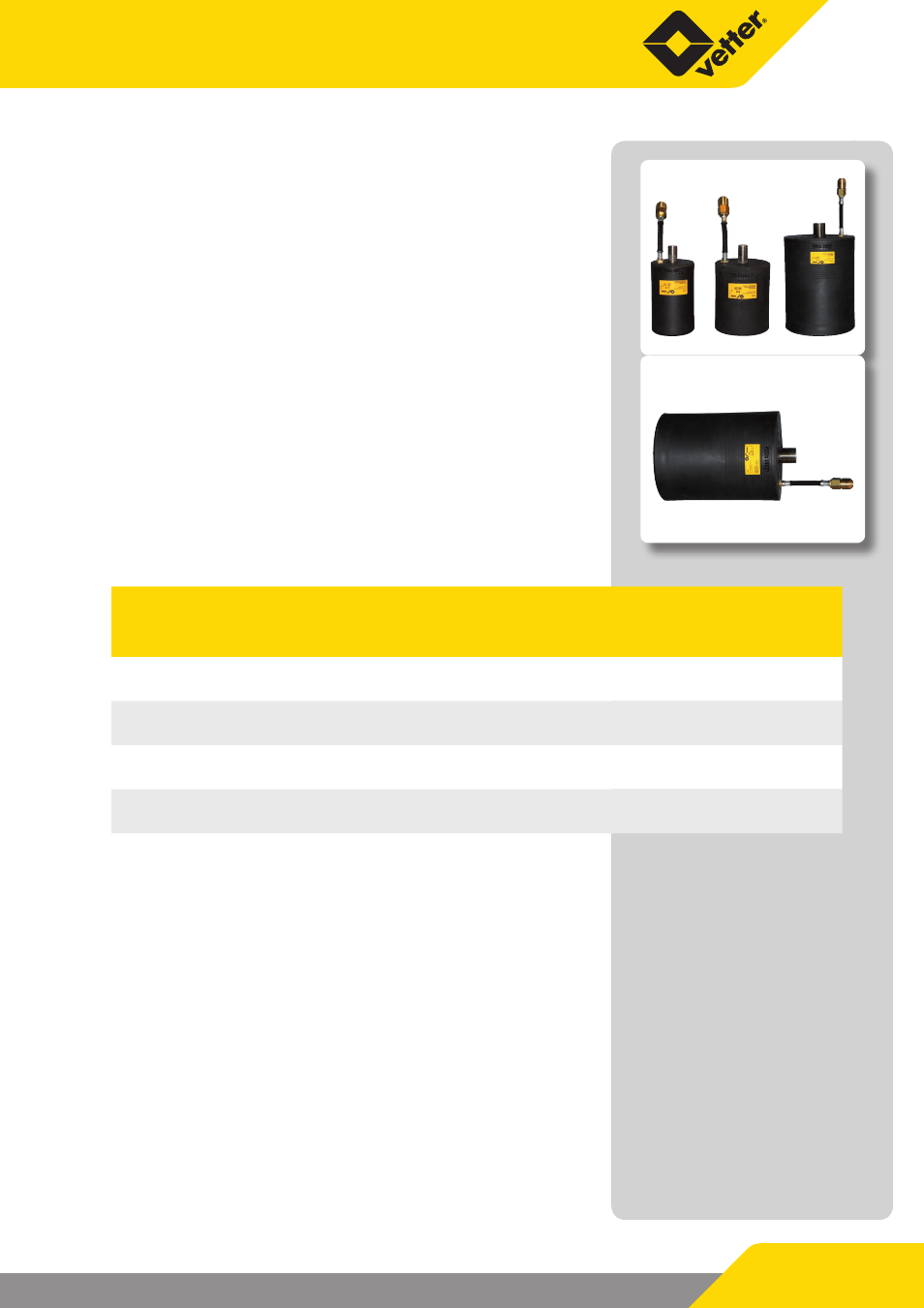

6.2 VETTER Mini Test Sealing Bags 2.5 bar

Description

Vetter mini test sealing bags 2.5 bar can be used for testing, sealing

and bypassing with repairs and maintenance work, e.g. sealing tests,

channel inspection, maintenance, repair and cleaning.

9

Please observe the permitted maximum counter-pressure of 5 m

water column, resp. 0.5 bar, when using mini test sealing bags.

9

Connect the inflation hose, 2.5 bar, to the mini test sealing bags

and the single controller, 2.5 bar fitting.

9

Position the mini test sealing bag, along its whole length, into

the pipeline and suitably secure it, e.g. with a structure support,

depending on the work to the carried out.

9

Inflation of the mini test sealing bag can be carried out according

to chapter 4.

Technical data

Mini Test Sealing

Bags 2.5 bar /

36.25 psi

Duct

Pipe

diameter

mm /

inch

Diameter

mm /

inch

Cylinder

length

mm /

inch

Total length

mm /

inch

Air

requirement

litres /

cu. ft.

Weight,

approx.

kg /

lbs

PDK 4/7

1441000701

6 mm

0.2 inch

40 - 70

1.6 - 2.8

37

1.5

155

6.1

250

9.8

3.5

0.12

0.4

0.9

PDK 10/15

1441035400

1/2“

100 - 150

3.9 - 5.9

90

3.5

150

5.9

300*

11.8*

2

0.07

1

2.2

PDK 12.5/20

1441035200

1/2“

125 - 200

5 - 7.8

115

4.5

150

5.9

300*

11.8*

4,4

0.16

1.2

2.6

PDK 20/30

1441035300

1“

200 - 300

7.8 - 11.8

185

7.2

250

9.8

410*

16*

18

0.64

4.5

9.9

* including valve connection

Standard test counterpressure of 10 m WC / 14.5 psi.

All rights reserved for technical changes within the scope of product improvement.