Vetter pipe and test sealing bags, Description, Technical data – Vetter Pipe and Test Sealing Bags User Manual

Page 16

Vetter Pipe and Test Sealing Bags

Page 16/33

6.

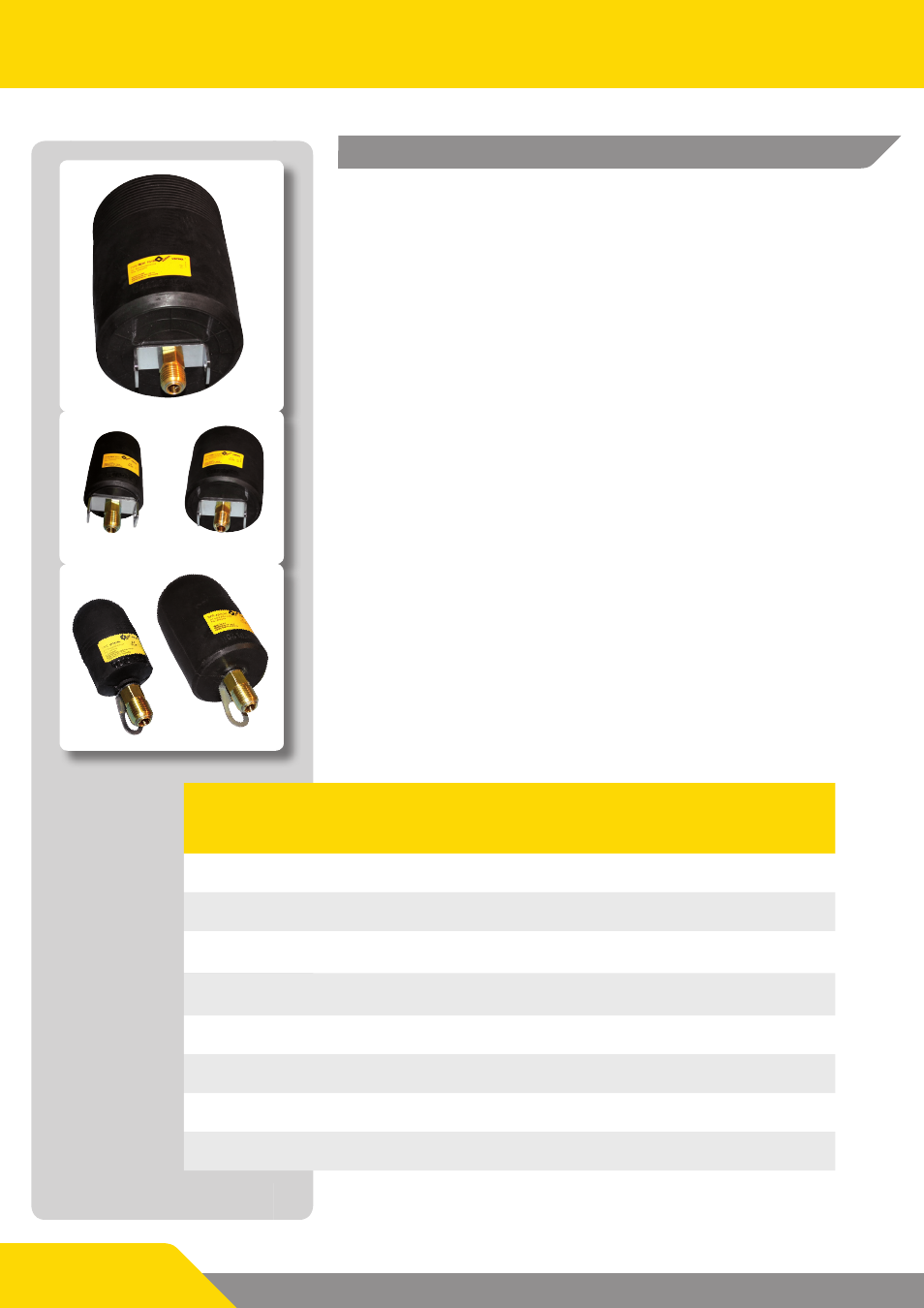

VETTER Round Profiles

6.1 Vetter Mini Pipe Sealing Bags 2.5 bar

Description

Due to their design, Vetter mini pipe sealing bags 2.5 bar can be used

in house connection lines, oil and petrol collectors and in front of cur-

ves.

9

Connect the inflation hose to the connection coupling of the se-

lected mini pipe sealing bag 2.5 bar and the output coupling of

the controller.

9

The air supply can be made by hand pump, foot pump, pressure

regulator and compressed air bottle or by a local compressed air

supply line, resp. by tapping air from a truck compressed air bra-

ke device.

9

Another possibility is the use of a foot air pump with a 2.5 bar

safety valve.

9

Insert or shift the sealing bag to the selected position and inflate

it to the permitted operating pressure of 2.5 bar.

9

The mini pipe sealing bag must be positioned along its whole

length on the pipe wall.

9

Securing lines can be used for removing the pipe sealing bag af-

ter work has finished.

Technical data

Mini Pipe Sealing

Bags 2.5 bar /

36.25 psi

Pipe diameter

mm /

inch

Diameter

mm /

inch

Cylinder

length

mm /

inch

Total length

mm /

inch

Air

requirement

litres /

cu. ft.

Weight,

approx.

kg /

lbs

RDK 2.5/4

1440000101

25 - 40

0.98 - 1.6

21

0.9

115

4.5

175

7

0.7

0.02

0.15

0.33

RDK 4/7

1440000201

40 - 70

1.6 - 2.8

37

1.5

155

6.1

215

8.5

2.5

0.09

0.2

0.44

RDK 7/10

1440025900

70 - 100

2.8 - 4

68

2.7

130

5.1

175

7

6

0.2

0.4

0.88

RDK 8/15

1440018800

80 - 150

3.1 - 5.9

72

2.8

120

4.7

170

7

11

0.39

0.4

0.88

RDK 10/15

1440010500

100 - 150

3.9 - 5.9

89

3.5

130

5.1

175

7

7

0.25

0.56

1.23

RDK 12.5/20

1440010700

125 - 200

5 - 7.8

115

4.5

150

5.9

195

7.6

30

1.06

0.76

1.68

RDK 15/20

1440018900

150 - 200

5.9 - 7.8

90

3.5

150

5.9

195

7.6

13

0.46

0.6

1.32

RDK 15/30

1440010600

150 - 300

5.9 - 11.8

145

5.7

200

8

245

9.7

54

1.91

1.42

3.13

Standard test counterpressure of 10 m WC / 14.5 psi.

All rights reserved for technical changes within the scope of product improvement.