Document and retain the test results – Vetter Pipe and Test Sealing Bags User Manual

Page 15

Page 15/33

The function test of the pipe and test sealing bag at the maximum

operating pressure in the permitted maximum pipe diameter

must only be carried out in a resistive pipe. A pipe which is too

weak will explode when a bag is inflated to the maximum opera-

ting pressure!

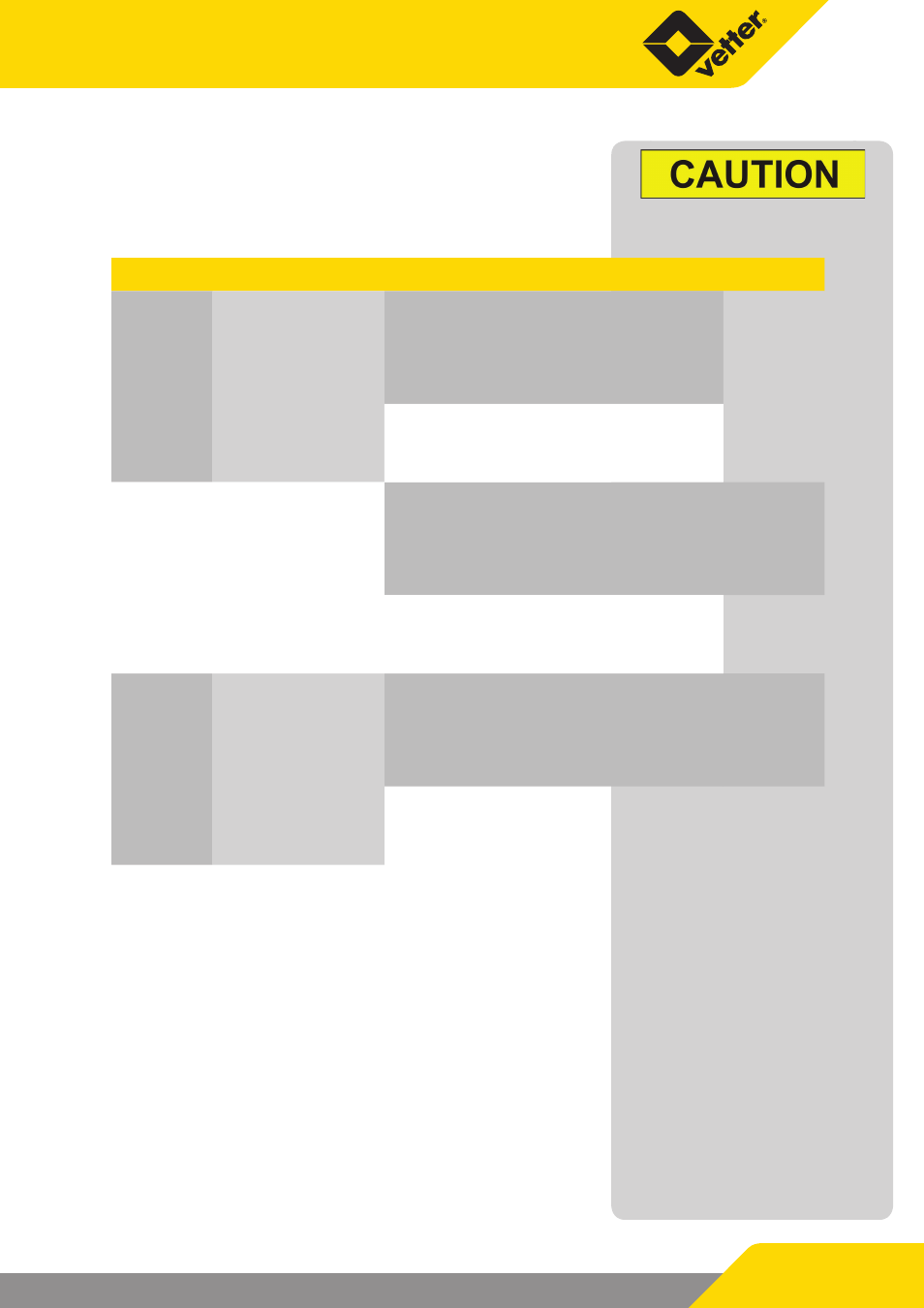

When?

What?

What is to be done?

Who?

Before each

use

Pipe and test sealing bags

along with controllers and

inflation hoses

(Safety equipment)

check for completeness

Visual check of the pipe and test sealing bags plus the

safety equipment (e.g., changes in form, cracks, fabric

damage, porous surfaces, etc.)

Function check of the safety equipment

Expert*

If there are any doubts after the visual check of the pipe

and test sealing bags regarding their safety, the bags

should be returned to the manufacturer for an in-depth

function test.

Manufacturer

After each use

Pipe and test sealing bags

along with controllers and

inflation hoses

(Safety equipment)

check for completeness

Visual check of the pipe and test sealing bags plus the

safety equipment (e.g., changes in form, cracks, fabric

damage, porous surfaces, etc.)

Function check of the safety equipment

Expert*

If there are any doubts after the visual check of the pipe

and test sealing bags regarding their safety, the bags

should be returned to the manufacturer for an in-depth

function test.

Manufacturer

At least once

annually

(otherwise,

according to

BGI 802, it

is no longer

permitted to

use the bags)

Pipe and test sealing bags

along with controllers and

inflation hoses

(Safety equipment)

check for completeness

Visual check of the pipe and test sealing bags plus the

safety equipment

(e.g., changes in form, cracks, fabric

damage, porous surfaces, etc.)

Function check of the safety equipment

Expert*

If there are any doubts after the visual check of the pipe

and test sealing bags regarding their safety, the bags

should be returned to the manufacturer for an in-depth

function test.

Manufacturer

If any kind of doubts concerning the safety arise during the visual

check or function check, abort the test and send the bag inclu-

ding the equipment to the manufacturer for further testing.

* An expert is a person who, based on his technical training and

experience, has sufficient knowledge in the sector of pipe-sealing

devices and is so familiar with the relevant governmental occu-

pational safety regulations, accident prevention regulations and

generally accepted laws of engineering (e.g., BG rules, DIN and EN

standards, technical rules from other EU member states or other

contracting states of the Treaty on the European Economic Area)

that he can assess the safe working condition of the pipe-sealing

devices. Source: BGI 802

Document and retain the

test results.