Thingmagic, a division of trimble, Smt reflow profile – ThingMagic Micro Hardware User Manual

Page 39

This drawing contains information that

is proprietary and confidential to

ThingMagic, Inc, and should not be

used without written permission.

ThingMagic, A Division of Trimble

Four Cambridge Center, 12

th

Floor, Cambridge, MA 02142 866-833-4069

M6e-Micro Module Integration

SMT Reflow Profile

SIZE

DWG NO

REV

A

850-0005-01

X8

SCALE

2:1

SHEET

2 OF 5

REV.

DESCRIPTION

DATE

BY

DRAWN BY

R. Herold

DATE

4/9/12

D

C

B

A

4

3

2

1

D

C

B

A

4

3

2

1

Reflow Solder MUST Be Performed

With Shield Can Facing UP

ONE Reflow Cycle Maximum

01

Initial Release

RH

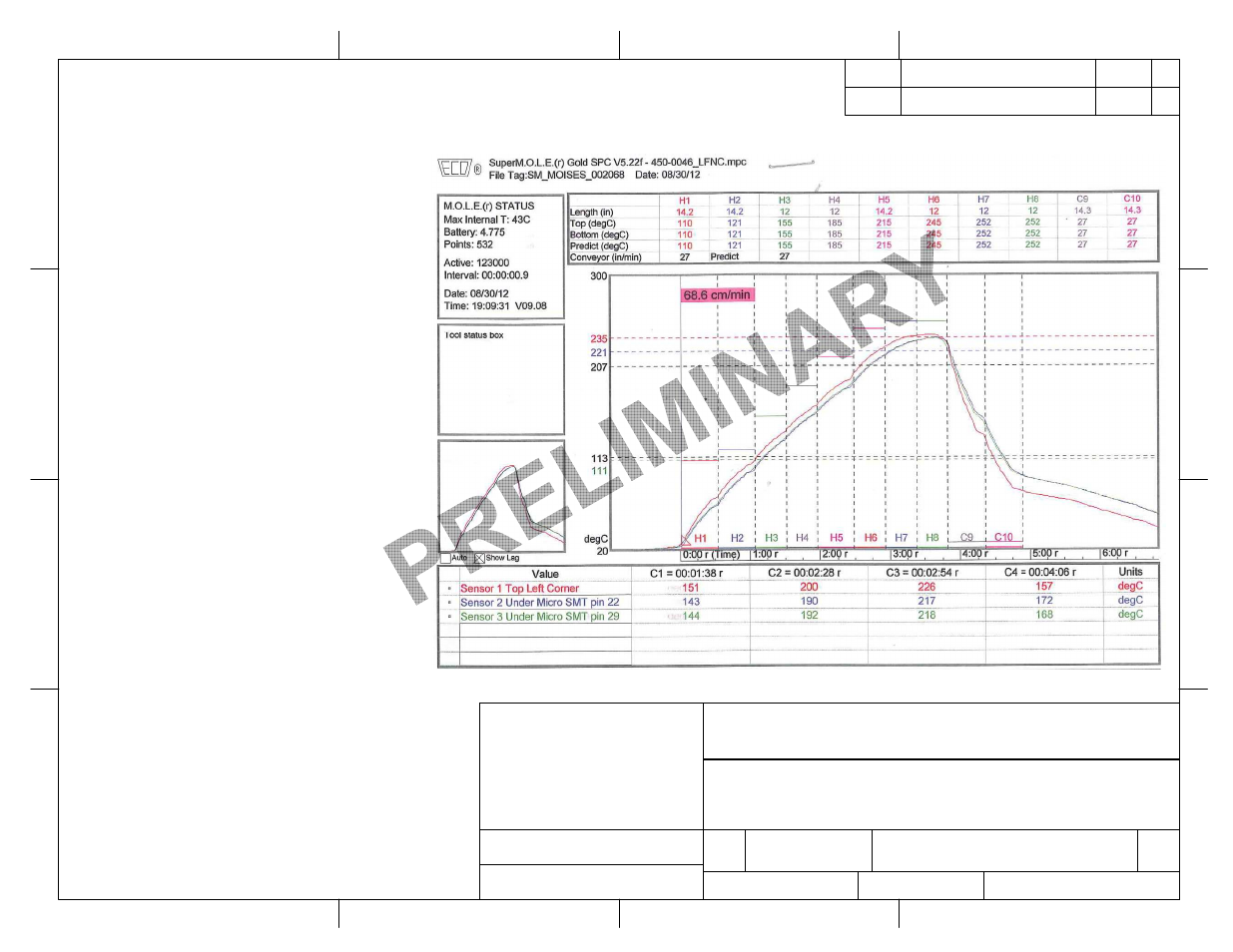

SMT Reflow Profile

Short profiles are recommended for reflow soldering

processes. Peak zone temperature should be adjusted

high enough to ensure proper wetting and optimized

forming of solder joints.

Generally speaking, unnecessary long exposure and

exposure to more than 245C should be avoided.

The profile shown has been used to assemble panelized

boards similar to those on Sheet 4 of this document .

For analyzing and adapting solder profiles a carrier

board was prepared with thermocouples (TC) as

described in the table.

To not overstress the assembly, the complete reflow

profile should be as short as possible. Here an

optimization considering all components on the

application must be performed. The optimization of a

reflow profile is a gradual process. It needs to be

performed for every paste, equipment and product

combination. The presented profiles are only samples

and valid for the used pastes, reflow machines and test

application boards. Therefore a "ready to use"reflow

profile can not be given.