Tjernlund SS1R SideShot (Discontinued) with UC1 Universal Control (Version X.04) 8504117 Rev 02/04 User Manual

Page 19

Yes, LED #2 (Green) lights up: The Fan Proving switch may not be closing, SS1-R High Limit may be tripped, wiring connections

are incorrect/broken or burner control(s) are not functioning properly. Push reset button on SS1-R high limit inside electrical box.

NOTE: Insufficient post-purge may cause limit to trip. If the limit switch trips, verify that the post-purge setting is long enough to

remove residual heat from the combustion chamber. If high limit trips repeatedly, do not operate the heater until the source of

excessive heat has been determined and repaired. If high limit will not reset and has an open circuit, replace high limit part num-

ber 950-0640. Verify inlet assembly sensing tube is clean. With SS1-R running, verify that venter performance is sufficient to

close fan prover. Draft gauge should read a minimum of -0.07" w.c. at SS1-R Prover sampling port. If draft gauge is unavailable,

verify that Venter performance is sufficient to close Fan Prover contacts by checking for continuity across switch. Replace Fan

Prover leads from P1 and P2 back on Fan Proving switch.

No, measured draft is less than -0.07" w.c.: Verify that SS1-R vent hood draft adjustment is at proper setting, see “Draft

Adjustment Procedure”, page 14. Visually inspect system for blockages. Confirm that maximum BTU/hr. input and vent pipe

lengths are not exceeded. See “Application Table” on page 1 for capacities. Check fan proving switch sensing tube for blockage.

Yes, measured draft is at least -0.07" w.c.: Replace fan proving switch part number 950-0750.

MAINTENANCE

SERVICE TECHNICIAN AND USER REQUIREMENTS

1. SS1-R must be visually inspected annually.

2. Verify over-fire draft, CO

2

and smoke readings are all correct. See “Draft Adjustment Procedure” on pages 14, 15.

3. Annually inspect vent pipe for evidence of corrosion. If any corrosion is found replace vent pipe and inspect venter.

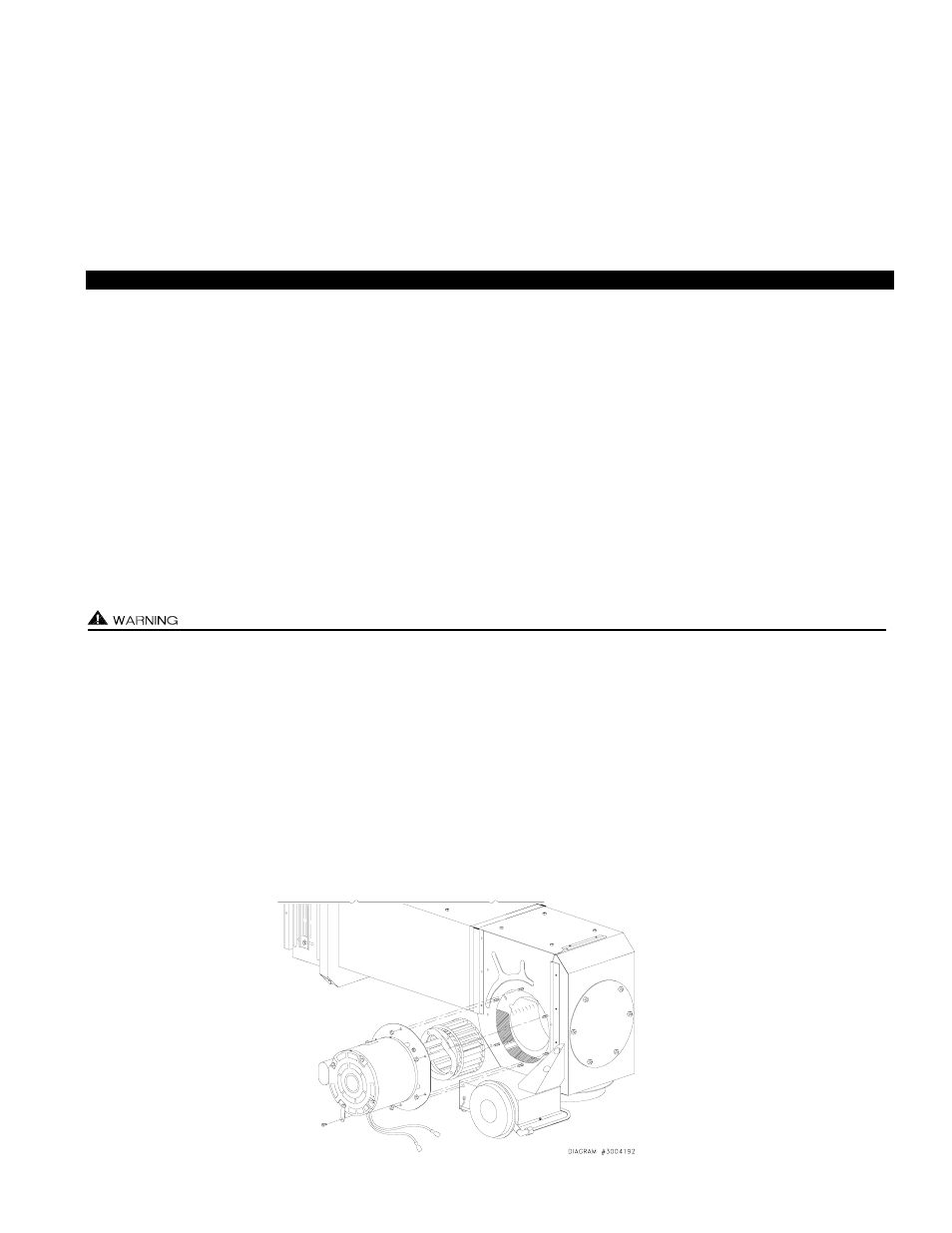

WHEEL INSPECTION (DIAGRAM T)

1. The SS1-R blower wheel must be inspected annually. Particulates, such as soot, oil impurities and sheet rock dust, can

prevent proper venting and will cause noise and vibration. Follow instructions, below for motor/wheel assembly removal.

2. Clean all particulate from wheel with a soft metal wire brush and soot cleaner. Clean the pocket of each blade, as well as the

rest of the wheel.

3. A wheel that exhibits large amounts of particulate or appears to be out of round should be replaced with a new wheel.

Instructions for wheel replacement are listed below.

REMOVAL AND REPLACEMENT OF MOTOR/WHEEL ASSEMBLY (DIAGRAM T)

Disconnect power supply to the SS1-R and heating equipment when servicing the SS1-R. Failure to do so may result in personal

injury and/or equipment damage.

1. Remove electrical box cover.

2. Disconnect the two SS1-R motor leads from the MTR & N terminals on integral UC1 board.

3. Remove motor bracket screw from electrical box.

4. Holding the motor, apply firm pressure towards the plenum of the SS1-R and remove the six motor mount nuts. Note: Hold the

assembly firmly; failure to do so could damage internal parts.

5. Slide motor/wheel assembly from Plenum. Grasp only the motor casing; do not damage wheel, shaft or other components on

Plenum. Do not rest assembly on wheel.

18

DIAGRAM T