Tjernlund SS1R SideShot (Discontinued) with UC1 Universal Control (Version X.04) 8504117 Rev 02/04 User Manual

Page 16

COMBUSTION AIR

Adequate combustion air is vital for proper combustion and for safe venting. Likewise, for proper SS1-R performance, adequate

combustion air must be available to the appliance. Many installers assume adequate combustion air is present, especially in older

homes. In some cases this is a false assumption, because many older homes have been made "tight" due to weatherization. Size

the combustion air opening(s) into the appliance room as outlined NFPA 31/NFPA 211. When installing a SS1-R, it is usually not

necessary to supply any more combustion air than normally required when conventional venting. Common symptoms of inade-

quate combustion air include: Fan Proving Switch short cycling, odor present at the end of burner cycle, outside air enters the

structure through the SS1-R Vent System on SS1-R/Appliance off cycle.

SYSTEM OPERATION CHECK-OUT

1. Adjust thermostat to call for heat.

2. Verify that the SS1-R and the burner motor both operate prior to ignition.

Allow heating equipment and SS1-R to operate continuously while performing steps 3-5.

3. Close all doors and windows of the building. If heating equipment is installed in utility room or closet, close the entrance door to

this room. Close fireplace dampers.

4. Turn on all appliances in the structure that exhaust indoor air during their operation, e.g. turn on clothes dryer, exhaust fans,

such as range hoods, bathroom exhaust and whole house fans.

5. Allow SS1-R and equipment to operate for at least five minutes. Tripping of the burner circuit by the Fan Prover Switch or

Limit during the five minute operation indicates an unsafe operating condition. Turn fuel supply off to appliance and DO NOT

OPERATE UNTIL UNSAFE VENTING CONDITION IS INVESTIGATED BY QUALIFIED SERVICE PERSONNEL.

6. Turn thermostat to the “off” position. Verify the SS1-R and the burner operate for several minutes, without a burner flame,

before the system shuts off. This is due to the Post-purge settings of the integral UC1 Universal Control. See page 4 for Pre

and Post-Purge settings.

7. Return all windows, doors and exhaust fans to their original conditions of use.

TROUBLESHOOTING OIL ODORS

Many problems can be eliminated quite easily by having the equipment properly set up by a professional oil-heat service contrac-

tor. The sophistication of today's heating equipment and instrumentation needed for efficient operation requires proper training.

There is no substitute for the work of a qualified oil-heat service professional. All trouble shooting recommendations that follow

assume the equipment is installed and maintained by a qualified service person.

Post-purge: A post-purge is always necessary on oil installations. The factory default post-purge time period is 2 minutes. Just

as a chimney continues to draft after the burner has shut-down, the SS1-R will continue to run to clear the vent system of residual

gases. The duration of the post-purge cycle is adjustable from 0 to 16 minutes. We recommend a minimum of 2 minutes post-

purge on oil.

15

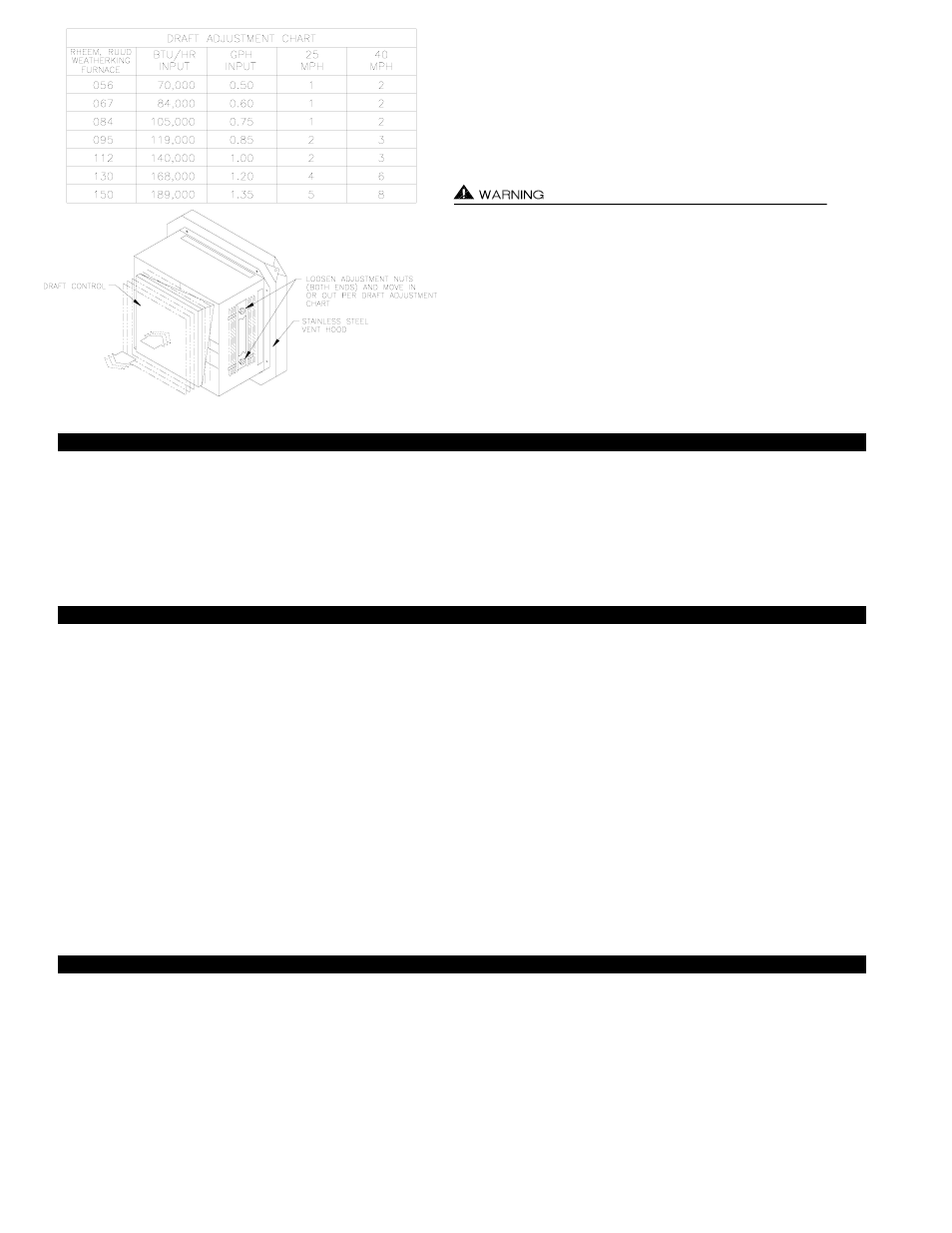

NOTES: All draft adjustments are approximate. This chart is

to be used for initial draft adjustment only. Subsequent draft

adjustments may be required to compensate for various field

conditions: wind, vent pipe resistance, building pressure,

multiple appliances, etc.

BTU/HR input ratings assume 30% or less excess air for

flame retention burners.

Do not exceed the recommended BTU/HR input range of the

SS1-R.

Under no circumstances shall the minimum draft adjustment

be used for the larger input range of this product.

Improper draft adjustment may result in the dispersion of flue

products (carbon monoxide) into the building interior.