Fig. e – Thetford 19613 - Mechanism Assembly User Manual

Page 2

Mechanism Assembly

Part #19613

Page 2

8. Remove Blade Seal from white mechanism plate. Discard.

9.

Important: If your mechanism plate has two holes at front (dotted lines in

Fig. D), AND no leakage is suspected at foam gasket area, you do not need

to install the new plate provided in this kit. Skip down to the heading “To

Replace Mechanism.”

To remove Mechanism Plate, loosen the 3 Screws in well nuts (WN,

Fig. D) and pull the plate off the bowl. If well-nuts do not come out with

the plate screws, either push them through to the interior or re-insert the

screws to pull them out. Discard plate and well-nut hardware.

10. Scrape off old Seal from china with sharp tool. Use mineral spirits or

alcohol to remove residue.

To Replace Mechanism Plate

(if it has been removed)

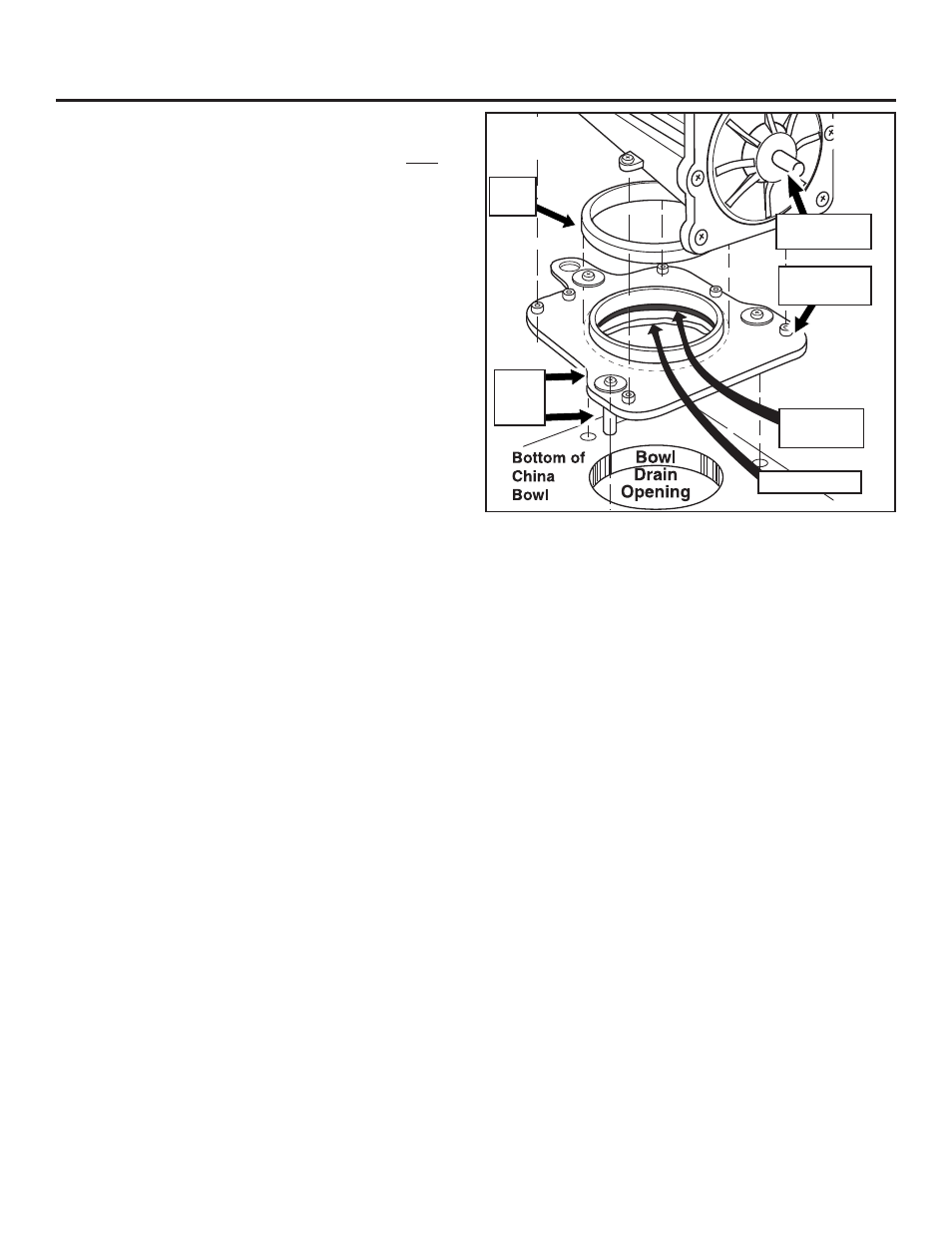

1. Apply a 1/4” wide continuous ring of caulk sealant around the top of the

exposed side of the flat foam seal. (Fig. E).

2. Line up well-nut assemblies on the mechanism plate with the holes in

the china bowl. Then line up the openings and press into place.

Lightly

hand-tighten the well-nuts to temporarily secure its position.

To Replace Mechanism

1. Wet blade seal with clean water.

2. Fully seat new blade seal, lip up, onto Mechanism Plate (Fig. E).

3. To avoid damaging blade seal, make sure blade in new mechanism is

fully closed. Turn mechanism lead screw counter-clockwise to close

valve (Fig. E).

4. Connect 2 Motor Leads, yellow-yellow, green-green (Fig. A).

5. Working from the back, position Mechanism in Toilet. NOTE: on some

low-profile units, it may be a tight squeeze. Align mechanism over

Mechanism Plate, press down and secure with four screws (MS, Fig.

D).

6. Turn toilet over to check centering. Loosen well-nuts to re-center if

needed.

Do the permanent tightening down of the well-nut screws

at this time by hand. Tighten in a diagonal pattern to get an even

seal. Be careful not to overtighten and cause deflection of the plate

at the edges. Wipe off excess sealant when done.

7.

If Overflow tube present (pre-3-16-03 Arias): Cut approximately 1” off

Overflow Tube. Remove silicone cap from Mechanism. Forming a full

loop, reattach to Mechanism. Tuck in and away from lead screw.

If Overflow tube not present: Leave silicone cap on Mechanism;

proceed to next step.

8. If you removed the Controller Assembly and/or the Switch Box, re-install

now, using the adhesive foam pads provided. If you removed Metal

Bracket, reinstall.

9.

High Profile: To install Extension Tube (Refer to Fig. C):

a. Lubricate sealing surface of Extension Tube Seal with silicone

grease.

b. Install Extension Tube Seal on Extension Tube.

c. Install Extension Tube and seal assembly on Mechanism. Make sure

that seal is seated at least 1/2 inch below Mechanism tube lip.

d. Ensure Hose Clamp on Mounting Flange Seal is tight.

e. Lubricate Mounting Flange Seal sealing surface with Silicone

Grease.

f. Install Mounting Flange and Seal assembly on Extension Tube. Make

sure there is at least a 1/2” overlap between the Extension Tube

and Mounting Flange Seal.

Low Profile: Replace the Mounting Flange Seal onto the lip of the

Mounting Flange. Install Mounting Flange to Mechanism. (No exten-

sion tube is used.)

10. Replace 2 Mounting Bushings with flat surface out.

To Test Mechanism Operation

1. Connect toilet to RV’s 12V DC power.

2. Turn on 12V DC to toilet at RV power distribution panel.

3. Press the Flush button on Key Pad and observe mechanism operation.

The solenoid valves will click on and off during the flush cycle.

4. Press both Key Pad buttons, twice, to open blade.

To Replace Toilet To Floor

1. Secure new Closet Flange Seal, lip side up, to Toilet.

2. Set Toilet close enough to hook up water supply.

3. Reconnect Water Supply Line.

4. Turn on water and check for leaks at the water connection. Correct any

leakage.

5. Position Toilet over flange. Arrange wiring clear of Mechanism Lead

Screw (Fig. E) and base of toilet.

6. Secure to floor with Lag Screws. Tighten.

7. Press Toilet flush button controls to add water and to flush test. Check

for leaks.

8. Resecure Bolt Caps.

Flat Foam

Seal

Mechanism

Lead Screw

Blade

Seal

Mechanism

Plate

Caulk Sealant

Fig. E

Well-nut

ass’y