0 service information, 1 troubleshooting guide, Table 4-1. troubleshooting table – Rice Lake Summit 3000 Low-Profile Package User Manual

Page 14: 2 periodic maintenance, 3 load cell replacement, Table 4-2. load cell replacement numbers

10

Summit 3000 Installation Manual

4.0

Service Information

The following sections describe basic service and maintenance procedures.

4.1

Troubleshooting Guide

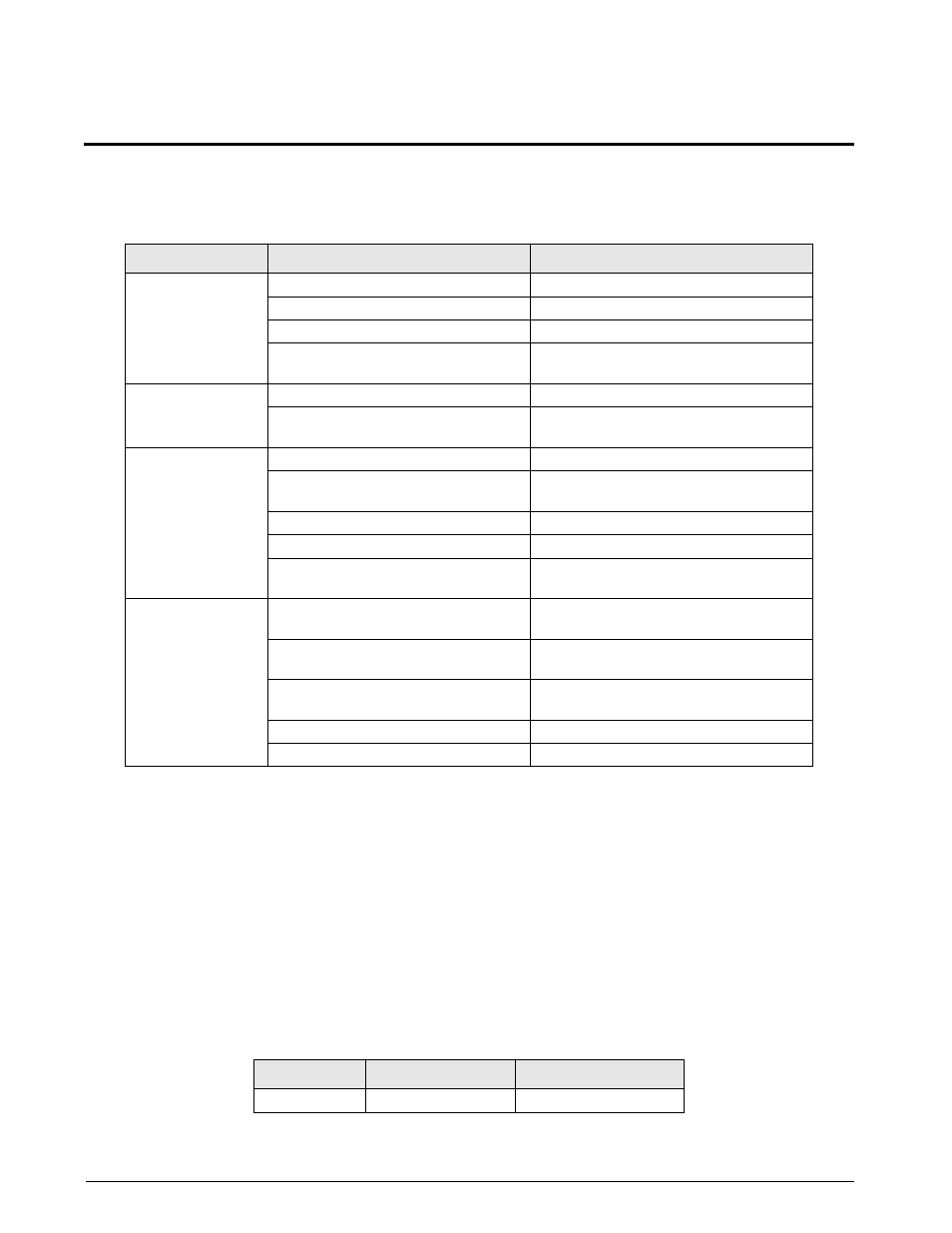

The following table lists some of the common problems and their suggested solutions.

4.2

Periodic Maintenance

The space between the platform side and pit frame, and the surface beneath the platform must be periodically

cleaned to prevent debris build up. More frequent cleaning of these areas is necessary with scales mounted in

pits.

Do not attempt to use scales with load cells that are not hermetically sealed in washdown applications. Water

damage is a common cause of failure in non-hermetically-sealed load cells. Use care with high pressure steam

washdowns for hermetically-sealed load cells. The steam may not damage the load cells, but the elevated

temperatures may cause incorrect readings until the unit cools to room temperature.

4.3

Load Cell Replacement

Replacement load cells can be ordered from Rice Lake Weighing Systems according to the part numbers listed

below.

Problem

Symptom Description

Solution

System does not

operate - no display

Power disconnected

Check and reconnect

Indicator fuse blown

Replace the fuse. Check for cause

Interface cable cut or disconnected

Repair

Signal leads incorrectly installed at the

indicator

Install according to indicator installation

manual

Display stays at zero

Indicator faulty

Service indicator

Load cell connections faulty

Check cable connections in junction box and

at indicator

Erratic weight

readings

Vibration near scale

Remove source of vibration or move scale

Platform not level to within 1/4 in.

Level scale by adjusting feet or shimming if

necessary

Load cell or cable water damage

Replace

Debris under load cells or platform

Clean

Indicator faulty

Use simulator to test indicator for stability.

Service indicator

Consistently high or

low weights

Indicator not properly adjusted to zero

Zero the indicator according to the indicator

manual

Platform binding

Obtain adequate clearance for free platform

movement

Indicator not calibrated

Calibrate according to indicator manual and

Section 3.3 on page 8

Load cells faulty

Test and replace load cells if necessary

Feet touching deck underside

Adjust feet downward to provide clearance

Table 4-1. Troubleshooting Table

Rice Lake PN

Summit Model #

Load Rating

30106

2K models

1000 lb (453.6 kg)

Table 4-2. Load Cell Replacement Numbers