1 trimming procedure, Trimming procedure, Electrical interface to indicator – Rice Lake RoughDeck AX User Manual

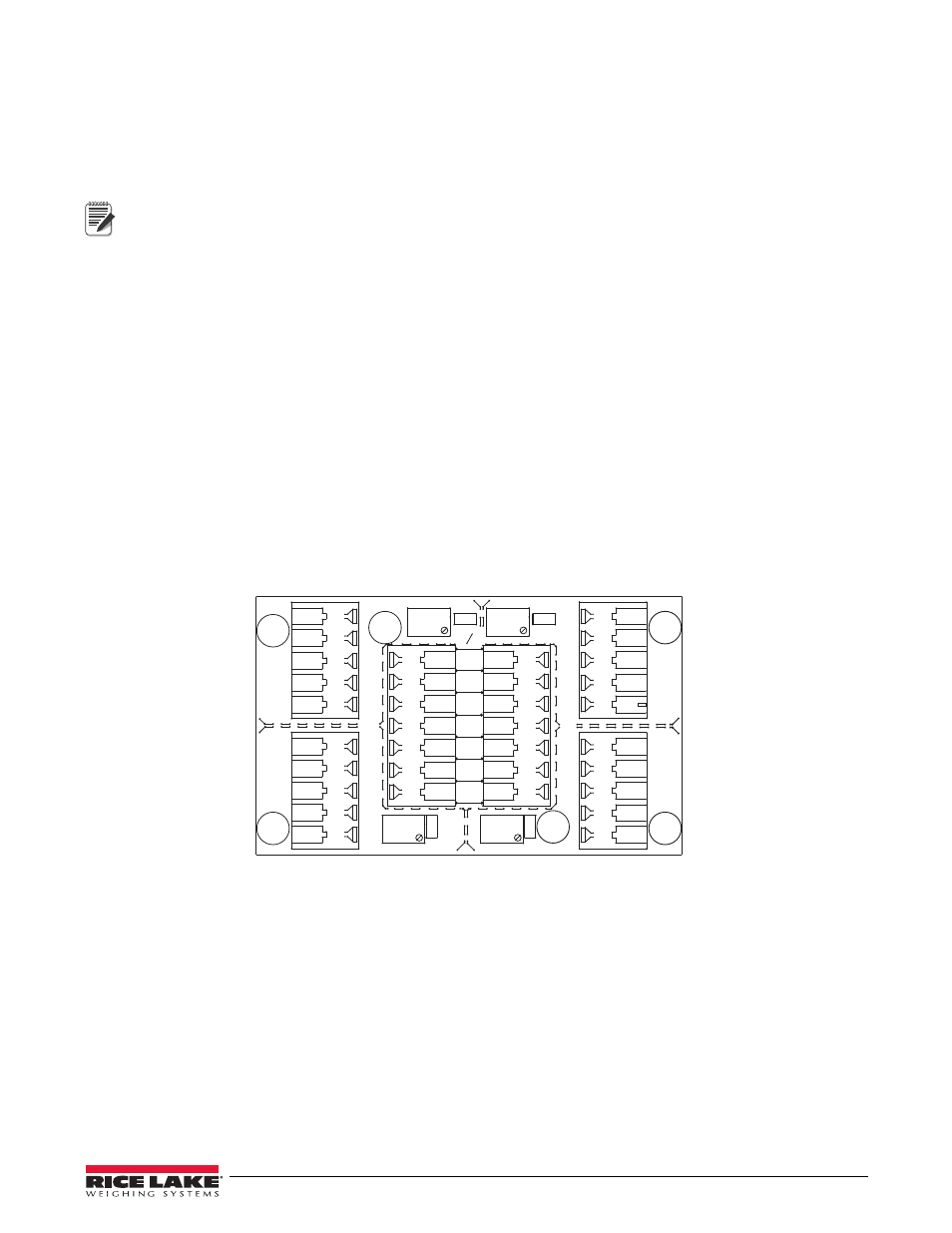

Page 9: Figure 2-3. signal trim main board

Installation

31

Electrical Interface to Indicator

Twenty feet of 6-wire cable to connect the scale to the weight indicator is supplied with each scale. The cable must

be routed to the indicator in a manner that will protect the cable from damage. Two methods of cable protection in

non-washdown applications are shown in Figure 4. When planning cable routing with either of these two methods,

leave a loose coil of excess cable under the scale to facilitate future lifting of the scale for servicing or cleaning on

the indicator terminal using the same procedure as inserting load cell cables to the appropriate connectors.

Note

If cables could be exposed to water or other liquids, bend a short downward loop in all cables near the cord grips so

any fluids draining down the cables will drip off before reaching the junction box.

2.5.1

Trimming Procedure

Trimming is a process of equalizing the output from multiple individual load cells. If needed, load cell output can

be individually trimmed with potentiometers.

Whenever a substantial amount of trim (more than 5% of normal output), seems necessary to equalize output,

check for other possible problems. The best trim is always the least amount of trim. When all errors except cell

mismatch and cable extensions or reductions have been corrected, continue with the trimming.

Use the following steps to properly trim the Tuffseal junction box.

1. Determine the number of load cells needed.

2. Make sure jumpers are in place to enable trimming of the cells corresponding to each load cell. See Figure

2-3 for the location of jumpers JP1, JP2, JP3, and JP4. Note that you need to remove jumpers for any

unused cells.

3. Set all potentiometers fully clockwise to give maximum signal output from each cell (cell below for

location of potentiometers).

JP4

JP 2

PT4

PT3

JP3

PT1

EXP

PT2

JP1

1

CELL4

1

CELL1

1

CELL3

1

CELL2

IND

-EX

-SI

SHD

+SI

+EX

M

R

N

I

-SI

S2 C

I

A

G

+EX

+SI

-SI

SHD

-EX

I

S

G

A

L

T

+SI

M

S

I

N

L

T

R

+EX

-EX

-SI

SHD

+SI

+EX

+SI

-EX

-SI

SHD

-EX

SHD

+SE

-SE

+EX

Figure 2-3. Signal Trim Main Board

4. Zero the indicator and place calibrated test weights over each load cell in turn. The amount of test weights

to be used will depend on the scale configuration; for specific recommendations, refer to Handbook 44

Field Manual, published by the Institute for Weights and Measures. For a four cell platform, it’s

recommended using 25% of scale capacity.

5. Record the value displayed on the indicator after the test weight is placed in turn on each corner (directly

over the load cell) without allowing the weight to overhang the sides. Allow the scale to return to zero each

time to check for friction or other mechanical problems. Select the load cell which has the lowest value as

your reference point. This cell will not be trimmed.

6. Replace the same test load over each cell in turn. Using the corresponding potentiometer, trim each cell

down to equal the reference load cell. As corner corrections are somewhat interactive, check all cells again