3 load cell replacement – Rice Lake RoughDeck AX User Manual

Page 13

30

RoughDeck HE AutoLift

4.3

Load Cell Replacement

Replacement load cell can be ordered from Rice Lake Weighing Systems.

Lift scale with chains and proper spreader bar and remove foot, then remove defective load cell. Disconnect load

cell cable from junction box and cut cable ties. When the cable is freed, pull cable out of the scale frame channels.

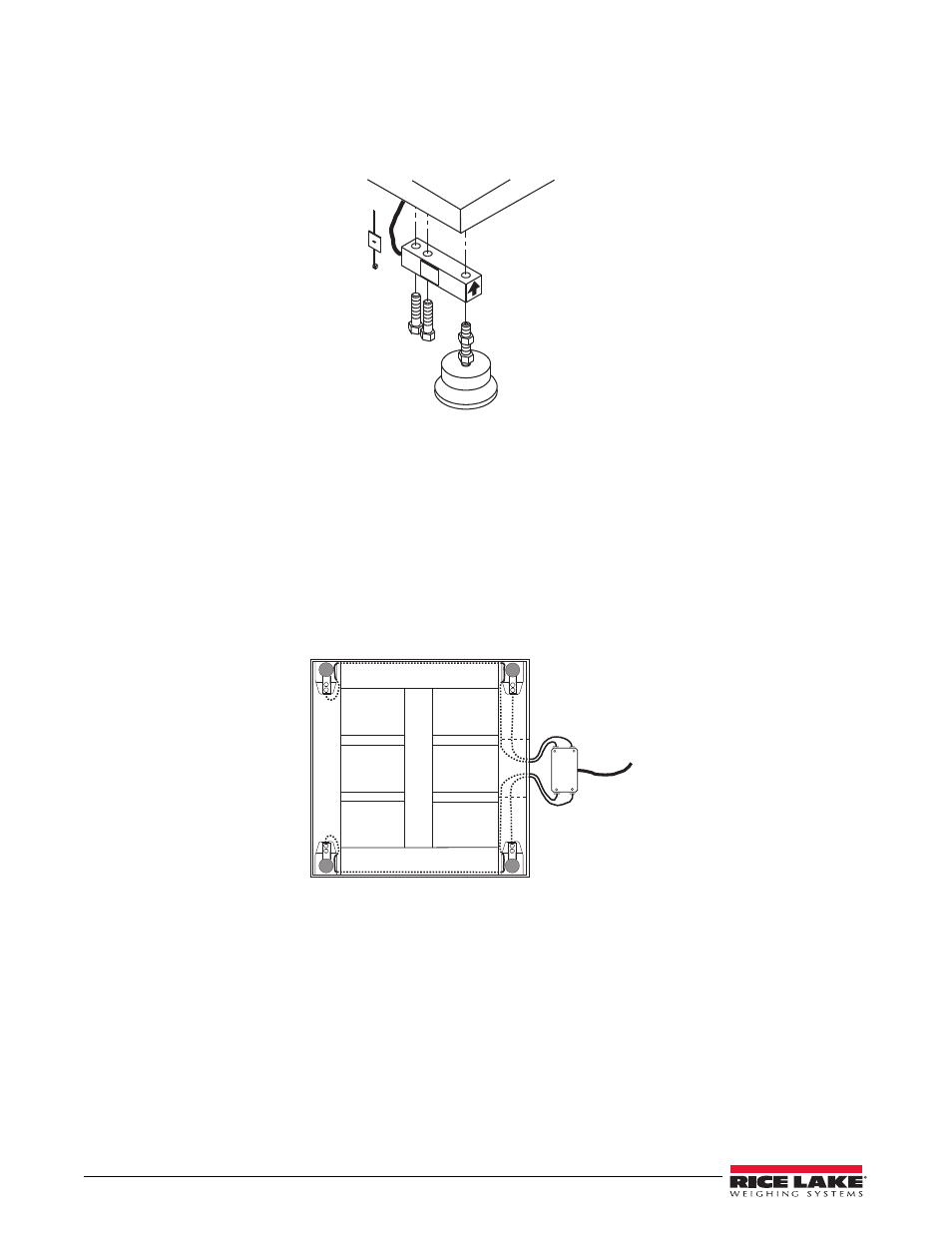

Figure 4-1. Load Cell Assembly

Follow the directions given below to install new load cells.

To reset overload stops after load cell installation, place a weight equal to 25% of the load cell capacity on the

affected scale corner. Screw in the overload stop until the indicator reading changes. Then back off the overload

stop 1/6 turn. Repeat for each corner where the load cell has been changed.

Lay out the four load cells near the corners where they are to be installed. Thread the cable from each load cell

through the conduit tubing in the frame and into the junction box according to the wiring diagram in Table 4-1.

Note that in Figure 4-2 both the scale and the junction box are viewed from the bottom. To verify correct load

cell/junction box terminal matching, see the numbers on the terminals inside the junction box and the corner

numbering diagram in Figure 4-4.

CELL 4

CELL 3

CELL 2

CELL 1

1

4

2

3

Figure 4-2. Bottom View of Scale

Check that the threaded holes for the load cell screws are free of debris. Use compressed air to blow out holes if

necessary. Position load cells with alignment arrows point up toward the deck and loosely install the hex head cap

screws provided, as shown in Figure 4-1. If the base is used with an access ramp, position the load cell to maintain

the dimension shown in Figure 4-3. With the torque wrench, tighten all bolts as follows (outboard bolts first):

•

30K-lb capacity: Torque to 250ft-lbs.