0 troubleshooting, 1 general, 2 drifting – Rice Lake Farm Bars - KLU Series Universal Weighbars User Manual

Page 14: 3 abnormally large reading, Troubleshooting

10

KLU Series Universal Weighbars Operator’s Manual

6.0

Troubleshooting

6.1

General

If you are having trouble with your load bars, a few simple procedures should help you determine where the

problem lies. First, inspect the scale for any physical damage. Take special note of the cable and connectors.

Wiggle the cables and connectors while watching the indicator display. If the readout jumps while moving a cable

or connector, there is likely a short or loose connection. Repair or replace the cable or connector as appropriate.

6.2

Drifting

If the scale readout is drifting, moisture may be present somewhere in the scale's electrical circuit. Check for

moisture in any of the connectors, junction boxes, or load bars. Dry any location where you suspect moisture is

present. If you find a location where moisture is collecting on a regular basis, seal the location with a waterproof

sealant.

6.3

Abnormally Large Reading

If the indicator shows a very large number and the readout cannot be changed using the indicators zero adjustment,

there may be a problem in the circuit. To locate this type of problem, a series of electrical resistance measurements

must be made. To perform these checks, you will need an accurate ohmmeter and a soldering iron.

To locate a faulty component with the ohmmeter, start by taking readings in the connector that plugs into the

indicator cable (this is the cable the runs into your scale). The connector has four pins labelled A, B, C and D, the

following chart lists the appropriate resistance readings. Remember, when making this type of measurement the

power must be OFF. Further, be careful that your fingers are not making contact with the probes on the ohmmeter

– if they are, the reading you take may be incorrect.

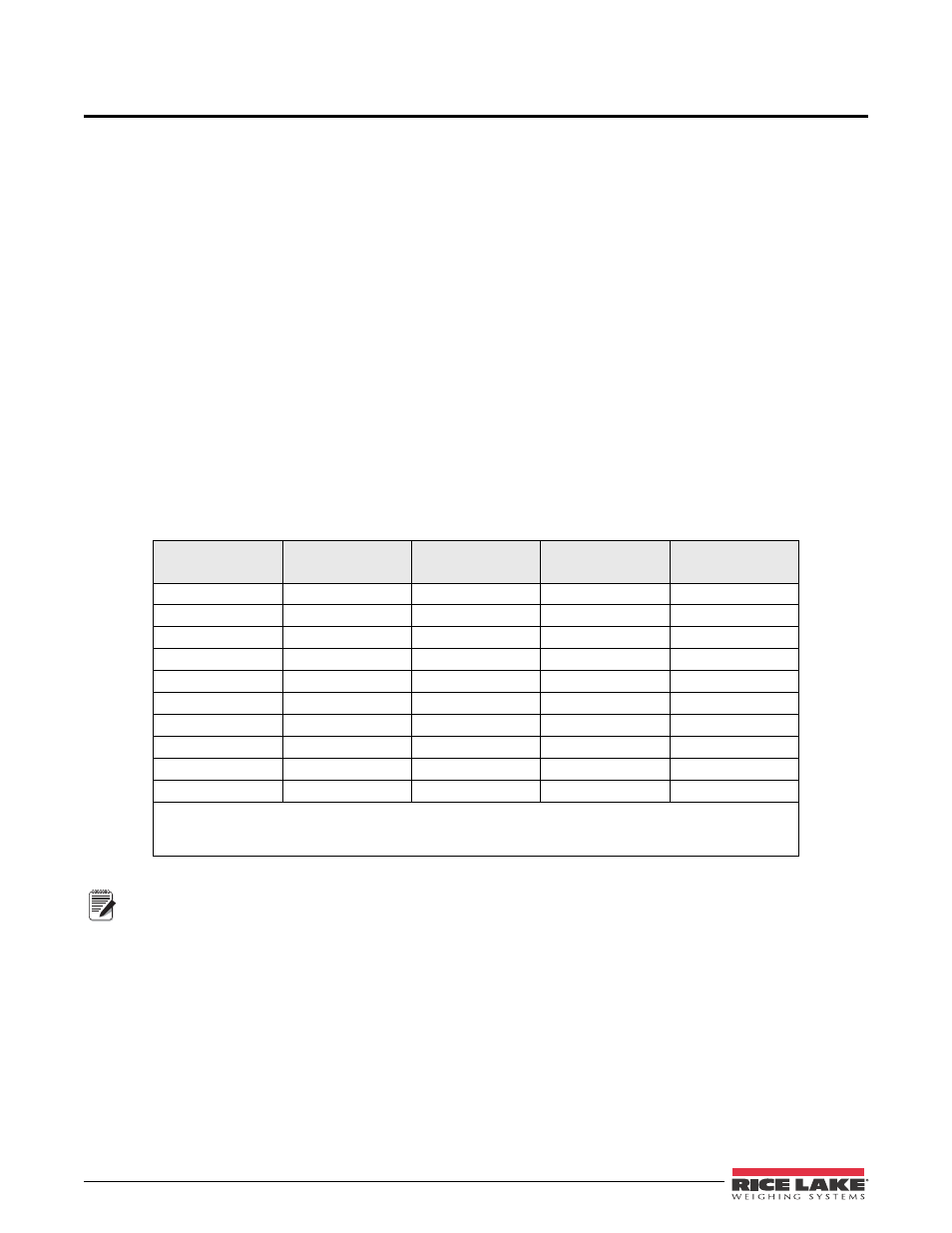

Table 6-1. Ohmmeter Readings

*Wire Color

Connector Pin

2-Load Bar

System

**One Load Bar

***Single Load

Cell

White – Red

D – C

145

Ω

290

Ω

395

Ω

White-Green

D – B

175

Ω

350

Ω

350

Ω

White-Black

D – A

145

Ω

290

Ω

395

Ω

Black-Green

A – B

145

Ω

290

Ω

45

Ω

Black-Red

A – C

197.5

Ω

395

Ω

790

Ω

Green-Red

B – C

145

Ω

290

Ω

745

Ω

White-Brown

350

Ω

Brown-Red

45

Ω

Black-GND

>10M

Ω

>10M

Ω

>10M

Ω

GND-Frame

0

0

0

*See Figure 6-1

**Valid only if Loadbar is disconnected from rest of circuit.

***Valid only if Load Cell is disconnected from rest of circuit.

Note

This chart is only valid at a temperature of 22°C. Resistance will vary slightly with temperature.

The readings in Table 6-1 should be within 5 ohms of the value shown. The readings are slightly temperature

dependent and as a result will not match Table 6-1 exactly. However, all the readings you take should differ from

the table by the same percentage. For example, if the resistance across pins D & C reads 142Ω ±1Ω, resistance

across pins D & A should also read 142Ω ±1Ω. In other words the values equal in Table 6-1 should also be equal

when you take your measurements. If the readings correspond to the values in the table an electrical problem in the

scale is not likely. If any readings across pins of the connector differ from the chart, each load cell must be checked

individually.