0 maintenance, 1 calibration, Maintenance – Rice Lake Farm Bars - KLU Series Universal Weighbars User Manual

Page 12

8

KLU Series Universal Weighbars Operator’s Manual

5.0

Maintenance

The most common type of problem that can occur is the load is not supported completely by the load bar pads. On

a regular basis check around and under the weigh apparatus to see if any debris has collected near the scale. Any

ice, dirt, mud or manure that builds up around the weigh apparatus can cause inaccurate readings. The scale should

be kept clean to ensure proper operation.

It should also be noted that an excess of debris on top of the scale could also cause problems. Depending on the

type of scale you have, there may be a limited range of weight you can “zero” off the scale. Always keep the build-

up of material on top of the scale to a minimum.

Lubrication of the bearings in your scale is also important. The bearings are located in the bearing collar, as shown

in the parts list diagrams in Figure 4-1 and Figure 4-2. Inject grease into the bearings using a syringe at least once

every two years. Use good high-pressure grease to lubricate the bearings completely. Do not use an excess of

grease – it should lubricate the bearing without bleeding around the foam seal.

5.1

Calibration

All Load cells are calibrated at the factory to reduce installation errors. Over the course of time, however, the load

cells may drift out of calibration slightly. Normally when a scale's load cells go out of calibration, the digital

indicator is adjusted to compensate for this.

The KLU Series Loadbars can be calibrated using the front panel, EDP commands, or the Revolution

®

configuration utility. Each method consists of the following steps:

•

Zero calibration

•

Entering the test weight value

•

Span calibration

•

Optional rezero calibration for test weights using hooks or chains.

The following sections describe the calibration procedure for each of the calibration methods.

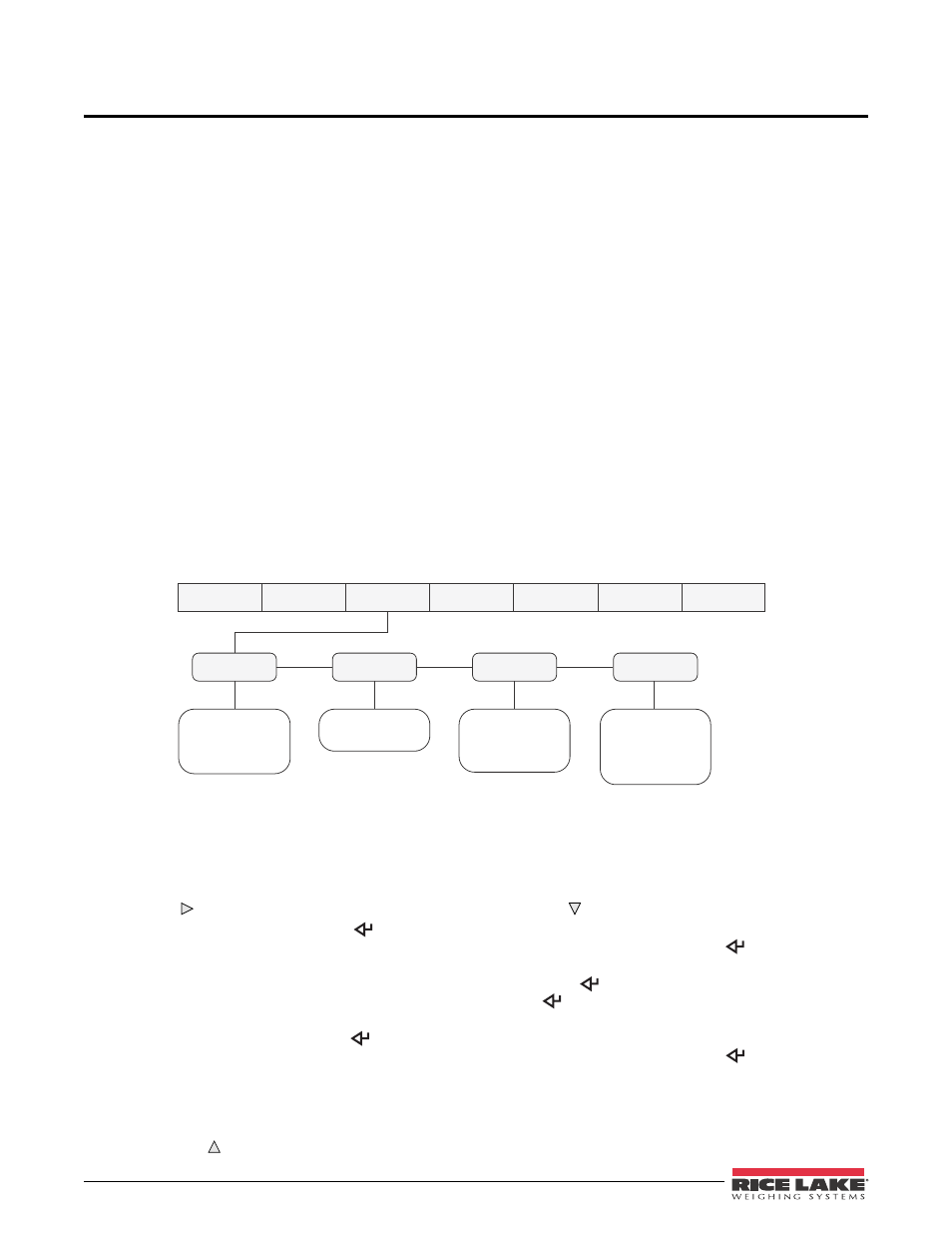

XXXXXXX

XXXXXXX

WZERO

*CAL*

Display and edit

zero calibration

A/D count value

Display and edit

test weight value

WVAL

*CAL*

Display and edit

span calibration

A/D count value

WSPAN

VERS

PROGRM

PFORMT

SERIAL

CALIBR

CONFIG

FORMAT

Press Enter to

remove offset from

zero and span

calibrations

REZERO

*CAL*

Figure 5-1. Calibration (CALIBR) Menu

Front Panel Calibration

To calibrate the indicator using the front panel, do the following:

1. Place the indicator in setup mode (display reads

CONFIG

) and remove all weight from the scale platform.

If your test weights require hooks or chains, place the hooks or chains on the scale for zero calibration.

2. Press until the display reads

CALIBR

(see Figure 5-1). Press to go to zero calibration (

WZERO

).

3. With

WZERO

displayed, press

to calibrate zero. The indicator displays

*CAL*

while calibration is in

progress. When complete, the A/D count for the zero calibration is displayed. Press

again to save the

zero calibration value and go to the next prompt (

WVAL

).

4. With

WVAL

displayed, place test weights on the scale and press

to show the test weight value. Use the

numeric keypad to enter the actual test weight, then press

to save the value and go to span calibration

(

WSPAN

).

5. With

WSPAN

displayed, press

to calibrate span. The indicator displays

*CAL*

while calibration is in

progress. When complete, the A/D count for the span calibration is displayed. Press

again to save the

span calibration value and go to the next prompt (

REZERO

).

6. The rezero function is used to remove a calibration offset when hooks or chains are used to hang the test

weights.

•

If no other apparatus was used to hang the test weights during calibration, remove the test weights and

press to return to the CALIBR menu.