Step 10) splicing the subsill – EFCO 526 Series User Manual

Page 29

EFCO 6/2012

Page 29

Series 526 Impact Installation Instructions

SECTION VI: Subsill Fabrication and Installation

Step 10) Splicing the Subsill

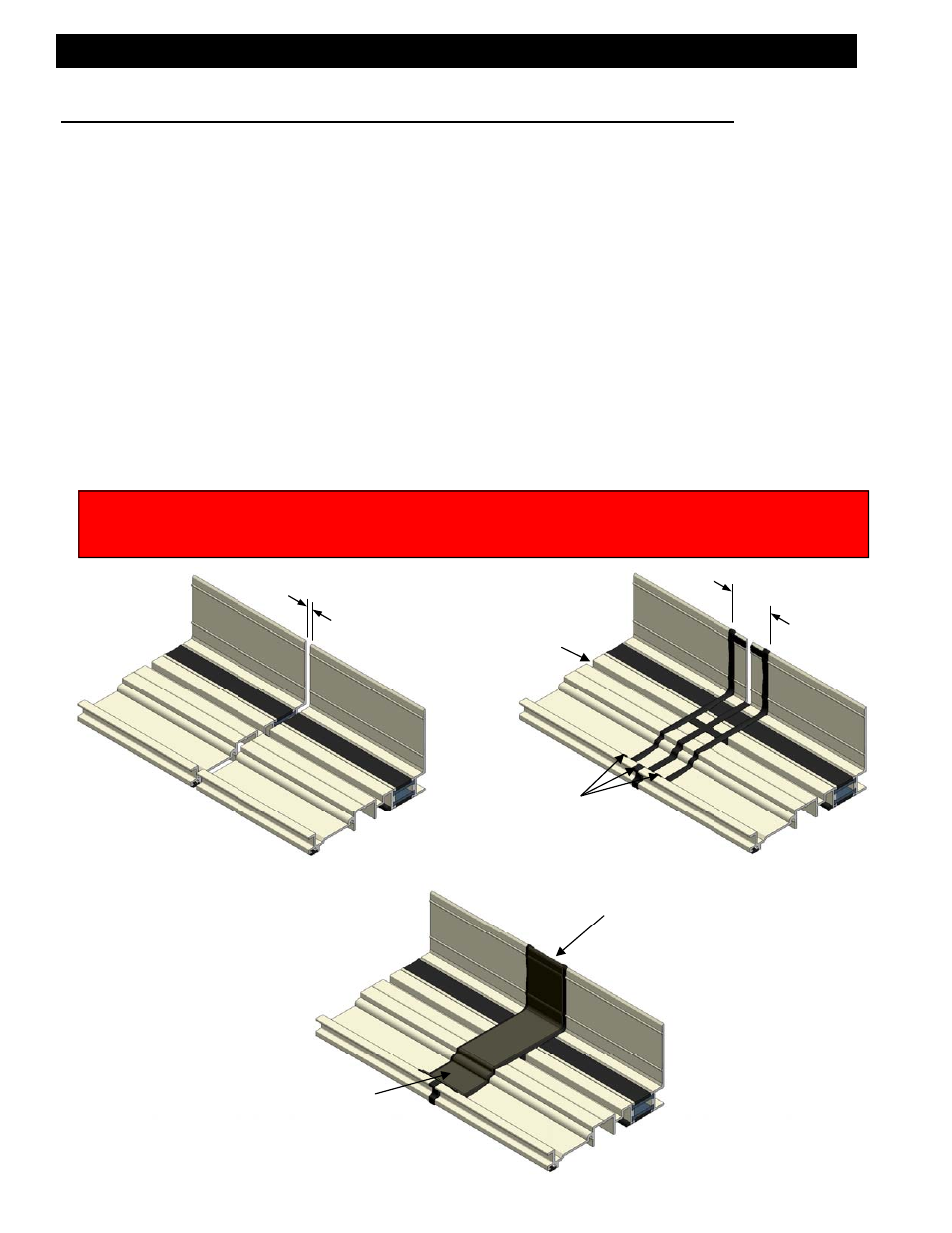

Verify that the subsills have been installed according to instructions on pages 24-28.

Splice areas should be centered at the vertical mullion only. Subsill length should never

exceed 20-25 feet. If a splice is required, leave a 1/4" gap between the subsill ends cen-

tered on a vertical mullion location. See figure 18. Use silicone type sealant and a strip of

WM01, bond breaker tape, 2" wide and approximately 7 1/2" long to create the splice ma-

terial. Apply the sealant to both sides of the subsill ends, fill the void between the subsills

from the exterior to the interior at the condition, and fill the sill leg receptor cavities on both

subsills to a width of 2". See figure 19. Ensure that the bond breaker tape is centered

over the 1/4" gap, and set the bond breaker tape in the sealant. See figure 20. Tool the

sealant over the bond breaker tape to create a watertight seal. If more sealant is required

to cover the edges of the bond breaker tape, apply the required amount. Ensure that the

splice joint does not interfere with anchor legs of the sill or the leg receptors of the subsill.

This is done by making sure the splice joint is located at the center of a vertical mullion.

Refer to the shop drawings or architectural drawings for mullion center lines.

1/4

2”

[Fig. 18]

[Fig. 19]

After splice tape is in

place, apply a cosmetic

seal along the 1/4” gap

at the interior of subsill.

WM01 Splice Tape

Sill Leg Cavity

Sealant

[Fig. 20]

Prior to applying sealant to the required areas, clean the area with Isopropyl Alcohol and a clean towel

that will not leave towel materials behind. Wipe off material with a sufficiently dampened towel to remove

all dust, oil, and cutting fluids from the required areas. Allow to air dry before applying any sealant.