EFCO 526 Series User Manual

Page 26

EFCO 6/2012

Page 26

Series 526 Impact Installation Instructions

Before installing the subsill, the exterior face location of the frame should be found using

benchmark information from the shop drawings or architectural drawings. The subsill

protrudes 1/32" to the exterior of the exterior face of the frame. Locate this line based on

the benchmark information, and snap a chalk line to follow when installing the subsill.

The subsill exterior angled leg should follow the chalk line for correct installation.

SECTION VI: Subsill Fabrication and Installation

Step 6) Benchmarks for Subsill Location

Step 7) Preparing and Sealing the Subsill for Installation

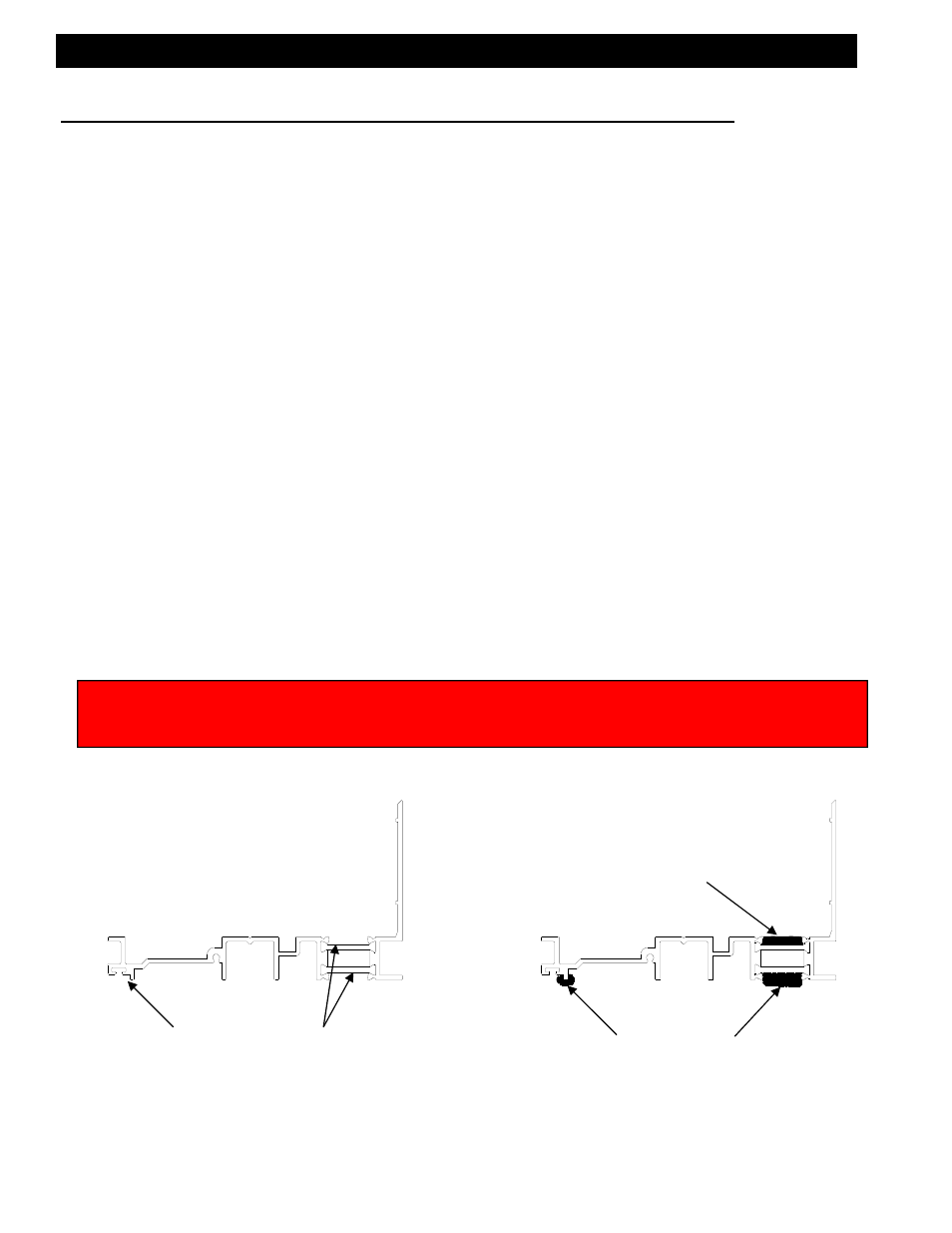

Regardless of whether an end dam is used or not, the subsill must be sealed to the

condition to create a watertight condition when it is installed. It is also necessary to run a

continuous bead of silicone on the top of the strut. See figure 11 below. Begin the

process by cleaning the bottom and top strut of the subsill with a degreasing solution, and

wipe it dry after all foreign material has been removed. See figure 10 below. When the

subsill is clean and dry, run a bead of silicone type sealant across the top of the strut, and

tool smooth. Then turn the subsill over, and apply a generous amount of silicone type

sealant to the areas shown in figure 11. This should be done just prior to the

installation of the subsill.

Silicone Sealant

[Fig. 10]

[Fig. 11]

Prior to applying sealant to the required areas, clean the area with Isopropyl Alcohol and a clean towel

that will not leave towel materials behind. Wipe off material with a sufficiently dampened towel to remove

all dust, oil, and cutting fluids from the required areas. Allow to air dry before applying any sealant.

Clean and Degrease

Thoroughly

Silicone sealant

tooled smooth across

top of the strut.