Subsill fabrication & install – EFCO 526 Series User Manual

Page 24

EFCO 6/2012

Page 24

Series 526 Impact Installation Instructions

STC6

[Fig. 7]

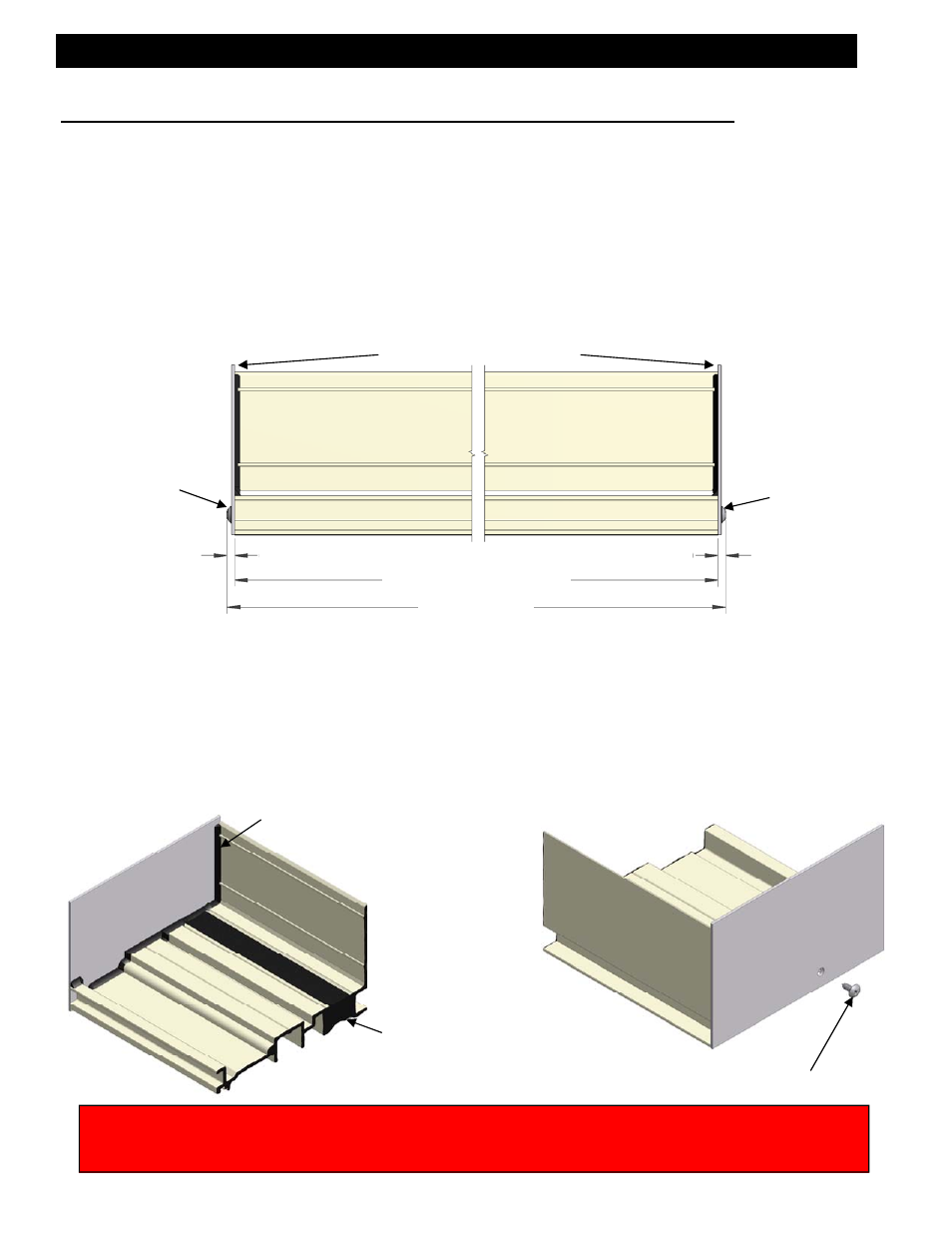

Prior to installing the end dam, apply a generous amount of silicone type sealant to the

end of the subsill. Insert the STC6 fasteners into the end dam, and attach it to the end of

the subsill. After the end dam is attached, the excess sealant should be tooled at the

interior of the subsill/end dam joint to provide a watertight seal. Apply more sealant, if

required, for a watertight seal. (See figures 6 and 7.)

[Fig. 6]

Tool Sealant

Butter the ends of the

subsill with silicone type

sealant prior to installa-

tion of the end dam.

SECTION VI: Subsill Fabrication and Installation

Step 1) Subsill End Dam Requirements

Step 2) Subsill End Dam Installation

Before installing the subsill into the rough opening, determine whether an end dam

(KP00) is required or not. If the surrounding condition does not have an open area or

can be used as a water dam, move to Step 3 on page 25. The first step to installation of

the end dams is to measure the rough opening width. The subsill length should be,

ROUGH OPENING WIDTH - 3/8". This formula will give enough room for the end dam

and attachment screws to fit on both ends of the subsill without interference with the

rough opening. (See figure 5 below.)

[Fig. 5]

STC6

STC6

3/16

3/16

SUBSILL LENGTH = R.O. - 3/8

ROUGH OPENING

KP00 END DAM PACKAGE

Prior to applying sealant to the required areas, clean the area with Isopropyl Alcohol and a clean towel

that will not leave towel materials behind. Wipe off material with a sufficiently dampened towel to remove

all dust, oil, and cutting fluids from the required areas. Allow to air dry before applying any sealant.