B. shear block – EFCO 525 Series User Manual

Page 35

SECTION VIII-FRAME INSTALLATION

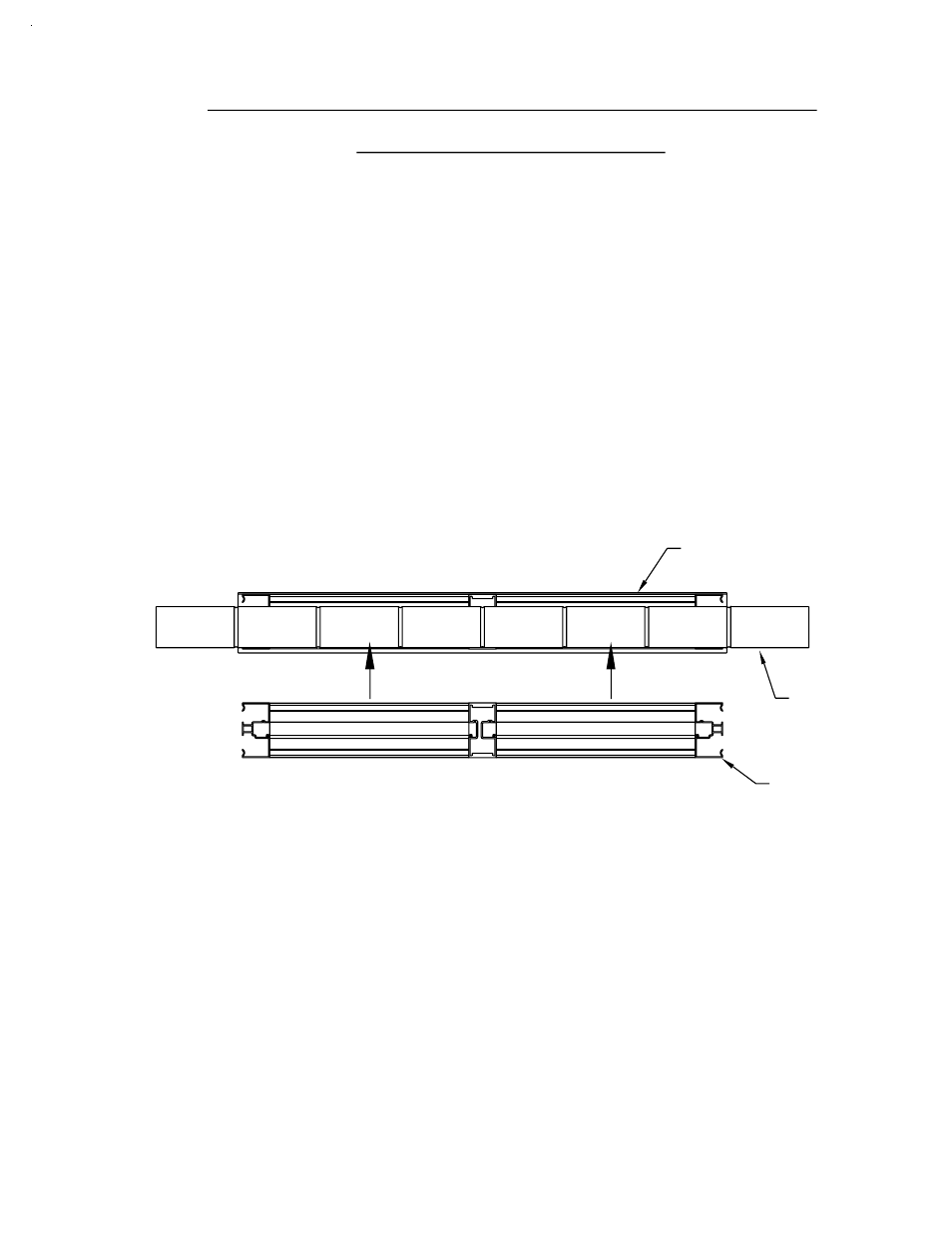

[FIG. 46]

B. SHEAR BLOCK

(CONT.)

PAGE 33

CONDITION

ASSEMBLED

FRAME

STEP 3) INSTALLING SHEAR BLOCK FRAMES

STEP 4) ANCHORING SHEAR BLOCK FRAMES

The frame should be supported at each vertical member to ensure

the shear block joints are not over stressed. Begin the installation by

evenly lifting and supporting the frame so that the bottom of the sill is

slightly higher than the top of the subsill. With even pressure, push

the frame into the rough opening. Once the frame is in the correct

position, allow the weight of the system to settle onto the subsill.

Additional weight may be required to press the sill down even with the

top of the subsill. Ensure that the frame is centered evenly in the

rough opening.

Once the frame is installed into the rough opening, ensure that it is

true and plumb. Anchor locations for the shear block frame will be

the same as for the screw spline frame. Follow the instructions as

shown in figures 34-37 on pages 26 and 27 for proper spacing of the

anchors. It may be advantageous to anchor perimeter jambs first and

heads second to ensure the correct line of the frame is maintained.

Seal and tool all anchor heads with 795 or equivalent silicone type

sealant. These are general anchor location guidelines. Size, space,

and embedment of anchors as required to meet structural load.

SUBSILL

525 IMPACT

DPS 1/2004