Snapping screw spline vertical mullions together – EFCO 525 Series User Manual

Page 32

SECTION VIII-FRAME INSTALLATION

A. SCREW SPLINE

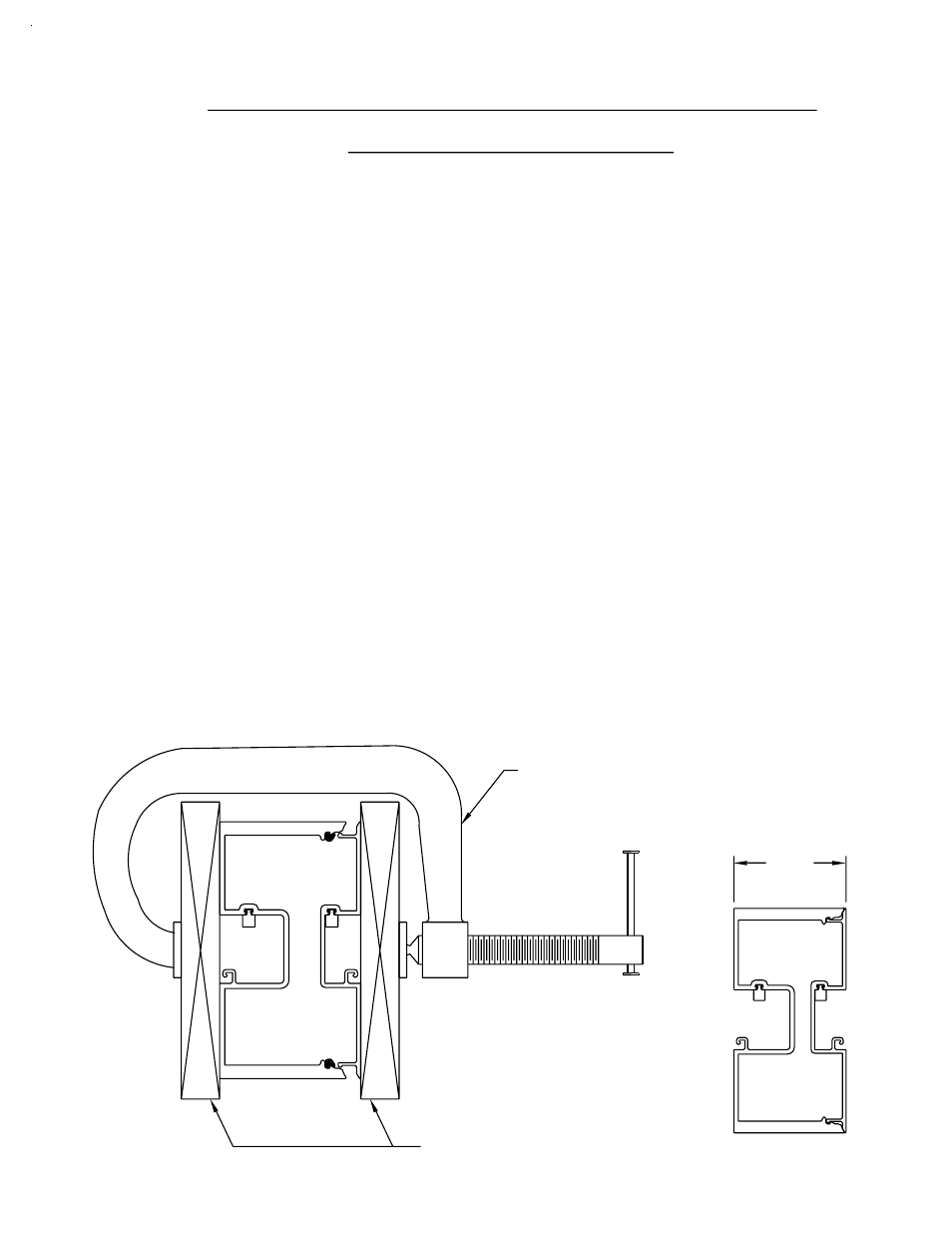

[FIG. 42]

[FIG. 43]

PAGE 30

(CONT.)

C-CLAMP

OR SIMILAR

WOOD BLOCK

OR SIMILAR

In some cases it may be necessary to use a clamping device to get the

mullions together properly, if they cannot be snapped by hand. To do

this, place one clamp at the bottom of the mullions using wood blocks to

protect the extrusions. Tighten the clamp until the mullion halves begin

to snap together. Place another set of wood blocks and a clamp at the

middle of the mullions and tighten it. Then repeat the same process at

the top. Tighten the clamps until the mullion halves are pressed

together. The sight line should be 2 1/2". It may be necessary to work

from one clamp to the next several times, or move the clamps to ensure

the mullions are snapped together evenly. DO NOT try to hammer the

mullion halves together! This will dent, bend, scratch, or deform the

mullions and may cause them to leak. Ensure that the previous module

is fully anchored before installing the 2nd module.

STEP 7) SNAPPING SCREW SPLINE VERTICAL

MULLIONS TOGETHER

525 IMPACT

2 1/2"

DPS 1/2004