Screw applied transom stop application, Step 6) screw applied transom stop application, Step 7) transom glass installation – EFCO 525 Series User Manual

Page 20

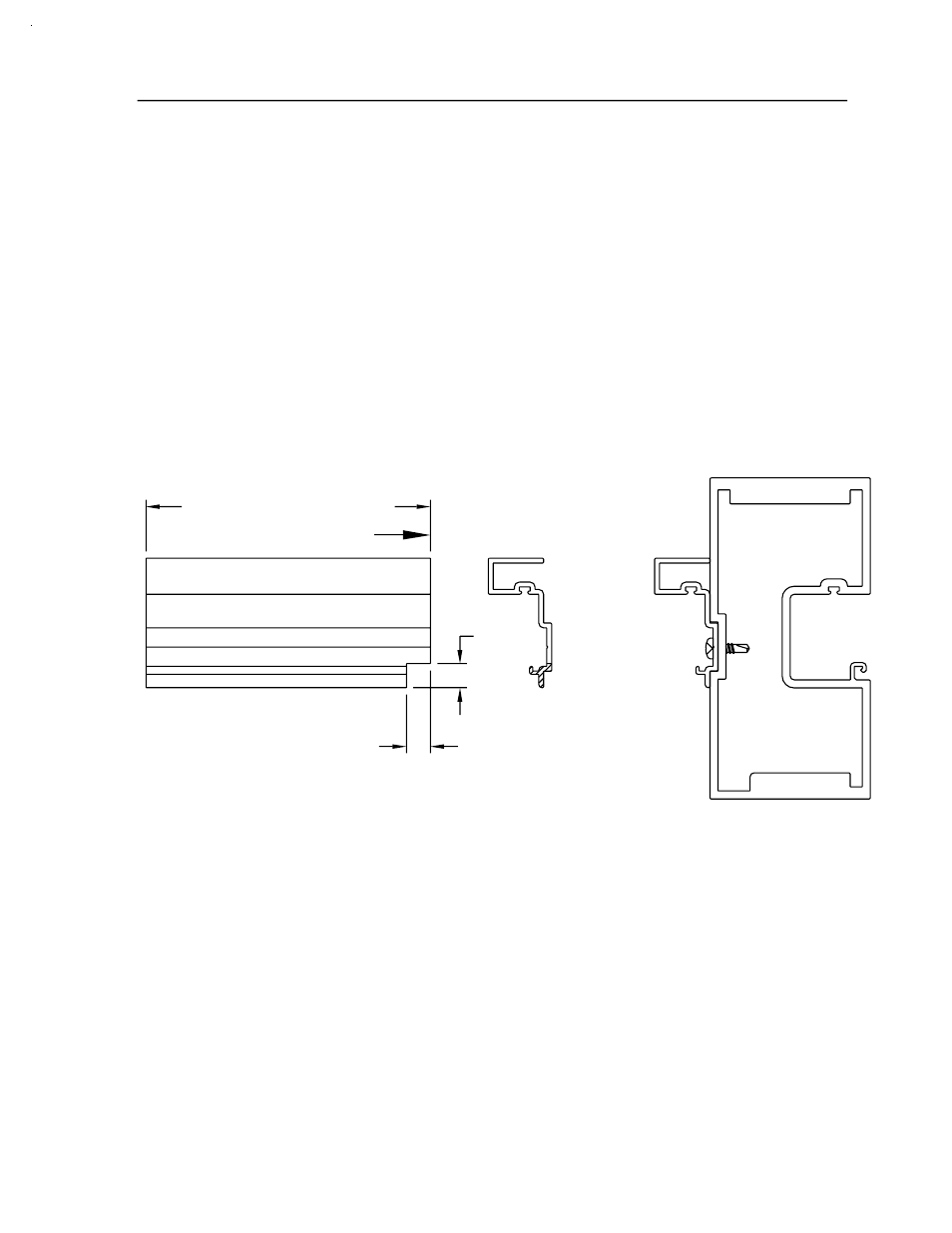

[FIG. 17]

SECTION VI - DOOR FRAME INSTALLATION

[FIG. 16]

DPS 1/2004

(CONT.)

PAGE 18

4478

4487

4487

BOTTOM OF TRANSOM STOP

STEP 6) SCREW APPLIED TRANSOM STOP APPLICATION

The screw applied vertical transom glass stops should be cut to fit

between the top of the door header and the bottom of the transom head.

The stop should be attached with STT6 TEK screws 2" from each end and

9" on center Maximum. To facilitate the installation of the door header

glass stop, a 3/8" X 3/8" notch must be made on the bottom of the screw

applied transom stop. See figures 16 and 17 below for notching and

application of the screw applied transom stop.

STEP 7) TRANSOM GLASS INSTALLATION

After the screw applied transom stop is applied, the glass can be

installed into the DLO. However, it may be advantageous to wait until

all frame installation is complete before the glazing is installed. Glazing

the transom at a later time may keep the glass from being broken while

other trades use the entrance area. Side loading is not required to

install the glass. It only has to be centered into the DLO and lifted into

the transom head so the setting blocks can be placed. See the dead

load charts listed in figure 58 on page 36 for setting block locations.

TRANSOM STOP CUT LENGTH

525 IMPACT

3/8"

3/8"