Side view – mullion splice – EFCO S5600 Outside Glazed User Manual

Page 22

EFCO CORPORATION 7/2012 PART NO. Y302

Page 22 of 26

Series 5600 Outside Glazed Installation Instructions

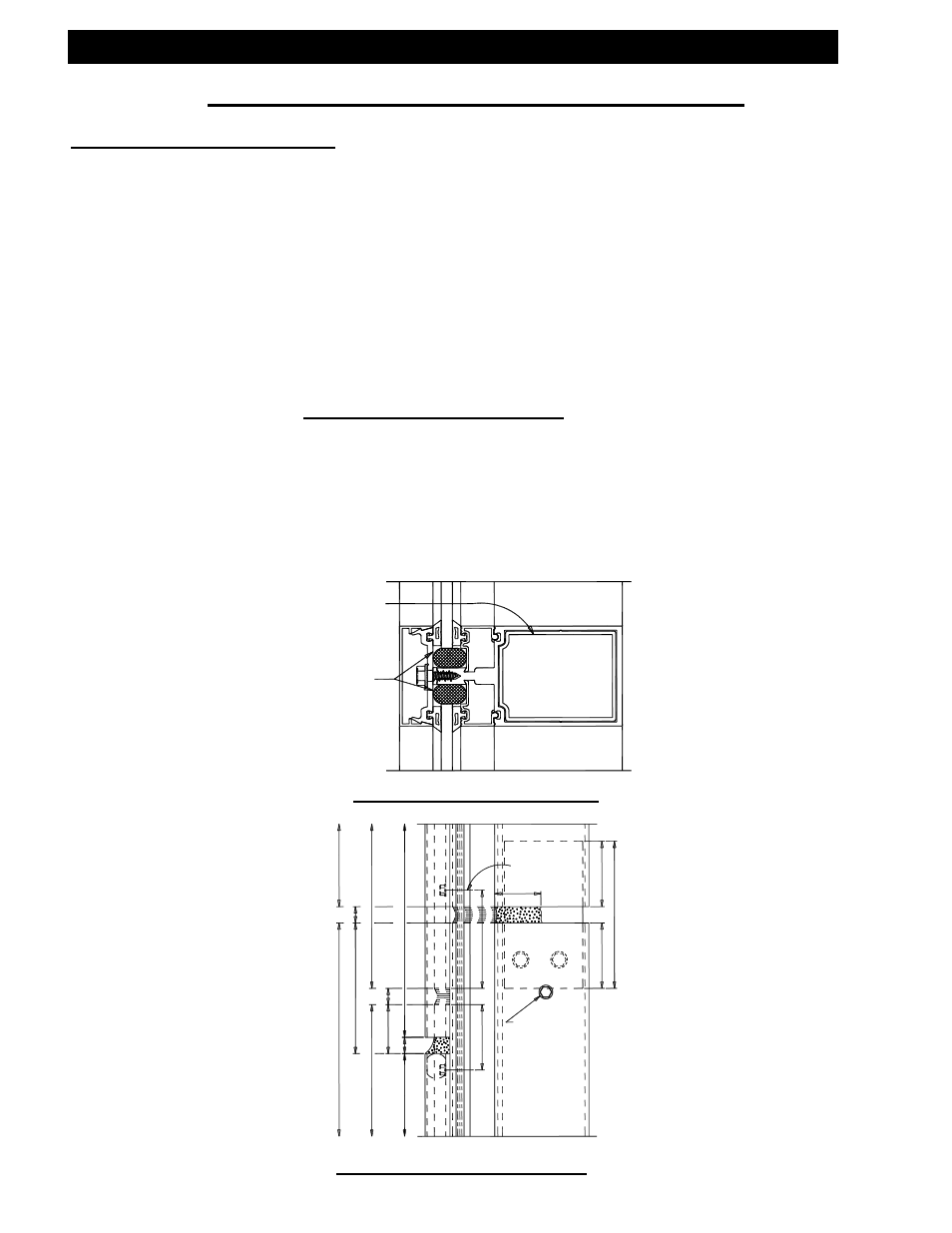

Section XIII: Vertical Splice Joints

Step #1 Locate Splice Joints

A.)

Splice joints should occur at the spandrel areas (if possible). Refer to approved final

shop drawings for actual locations.

B.)

Depending on the specific job requirements, splice sleeves may be shop or field

assembled in the top of the lower mullion. If materials are field fabricated, use the

following assembly instructions. Where head clearance is sufficient to allow the top

mullion to be lifted over the splice sleeve, a retractable sleeve will be used. The

sleeve must be taped into the bottom of the top mullion and dropped down to the

stop screw in the mullion below.

C.)

GENERAL NOTE: The following page depicts a splice joint of ½”. The required joint

width must be determined in the design stage and shown on the approved Final

shop drawings, on a job-by-job basis. Keep in mind that a typical curtain wall can

accommodate ¼” total vertical movement. The splice joint, horizontal glazing

pocket immediately above the splice, and slotted wind load anchors, must all be

considered when vertical movement exceeds ¼”.

D.)

Refer to this section for cover splice, pressure plate splice relative locations, and

sealing instructions.

E.)

Once a final check of expansion joint placement and mullion position is made, the

final match drilling of mullion through anchor holes may be completed.

Plan View – Mullion Splice

Splice Sleeve

Stop Screw

Mu

lli

on

L

en

gth

Cover Le

ngth

4”

2”

As

Req’d

1”

1/2

”

Pressure P

late

3”

Mi

n.

Field install backer rod

at the pressure plate

joint to back-up sealant.

Mullion splice sleeve

with bond breaker tape.

Side View – Mullion Splice

1” Minimum

Pressure

Plate Screw

M

ulli

on Le

ngt

h

Pressure P

late Le

ngth

Cover Le

ngth

As

Req’d

2”

4”

2”

See page 20 for multiple isometric

views of splice assembly.