EFCO S5600 Outside Glazed User Manual

Page 19

EFCO CORPORATION 7/2012 PART NO. Y302

Page 19 of 26

Series 5600 Outside Glazed Installation Instructions

Section VII: Glazing Installation

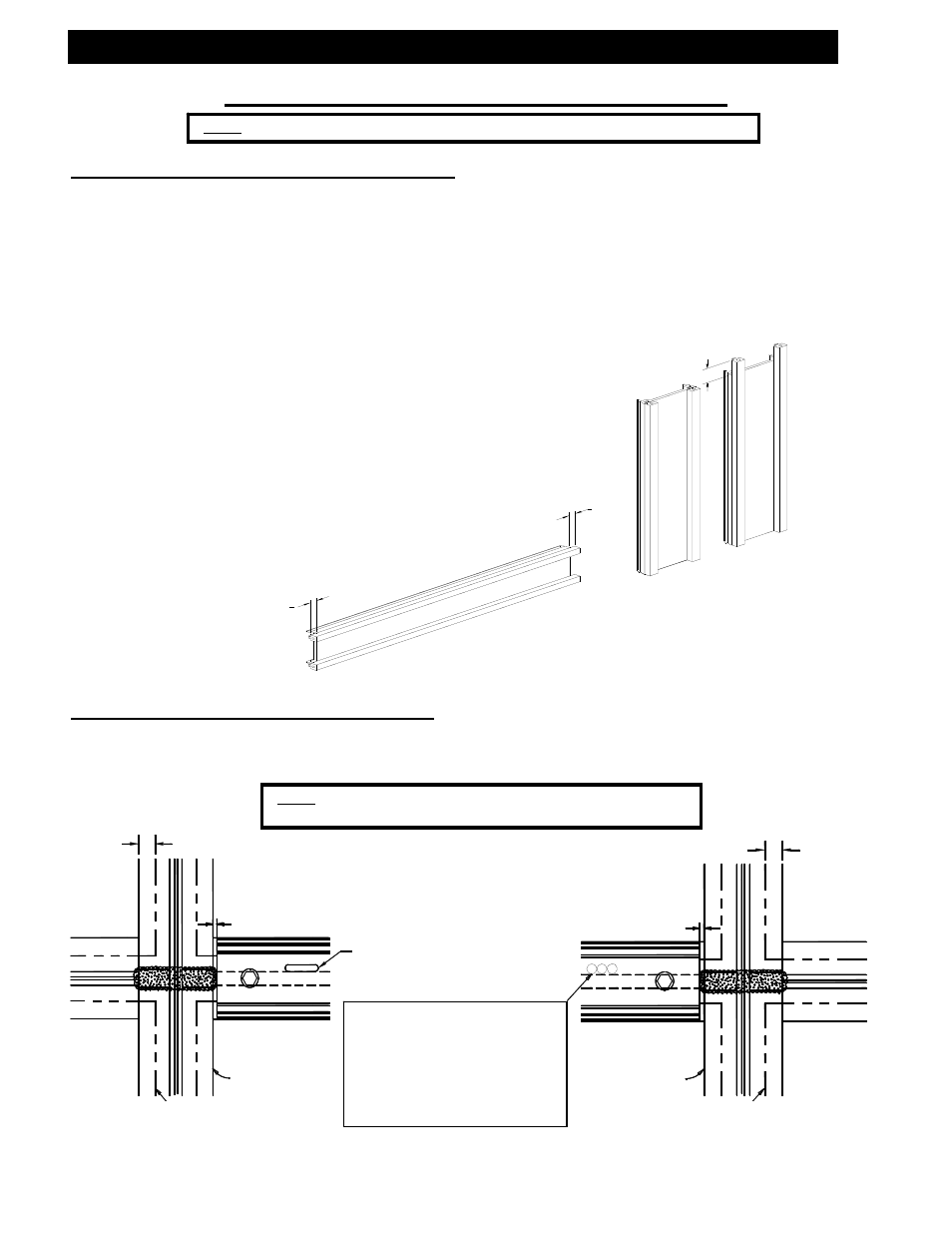

Step #1 Prepare Exterior Pressure Plates

A.)

Remove exterior gasket material from the reel and allow to relax and shrink.

B.)

Apply glazing gaskets to the pressure plates. Gaskets must be cut flush at both

ends of the vertical pressure plate except in multi-story applications, where gaskets

are to extend 1” beyond the top end to cross the expansion joint. The pressure

plate should extend 3” past the splice. [See Section IX: Vertical Splice Joints]

C.)

Cut the horizontal gaskets ½” longer than the pressure plate length and apply so

that ¼” extends beyond each end.

Step #2 Apply Exterior Pressure Plates

A.)

Apply sealant to the face of the joint plugs prior to installation of the vertical and

horizontal pressure plates.

Note: All anchors must be “FIXED” before glazing installation begins.

Edge of Glass

Line of Mullion

3/16” X 1” weep slot

centered 4” off each

end of the pressure

plate.

½” Glass Bite

(typical)

Note: Horizontal pressure plates are cut D.L.O. -1/4”.

The erector must split the difference on both ends.

1"

1

4

"

1

4

"

Typical horizontal

gasket extended ¼”

each end.

Typical vertical

gasket cut flush

top and bottom.

Vertical at multi-

story, gasket

extended 1” at top.

Horizontal Pressure Plate

Vertical Pressure Plate

OPTIONAL WEEP HOLES

5/16” dia. weep holes

Drill 3 side by side centered

4” off each end of pressure

plate. Locate C/L of holes

5/32” above top of tongue.

Line of Mullion

Edge of Glass

½” Glass Bite

(typical)

1/8”

1/8”