Adjusting the air flow – Dynojet Compressed Air Air/Fuel Ratio Module User Manual

Page 31

O N - B O A R D D Y N O I N S T A L L A T I O N

Installation

Version 5

Compressed Air Air Fuel Ratio Module Installation and User Guide

A-5

A

DJUSTING

THE

A

IR

F

LOW

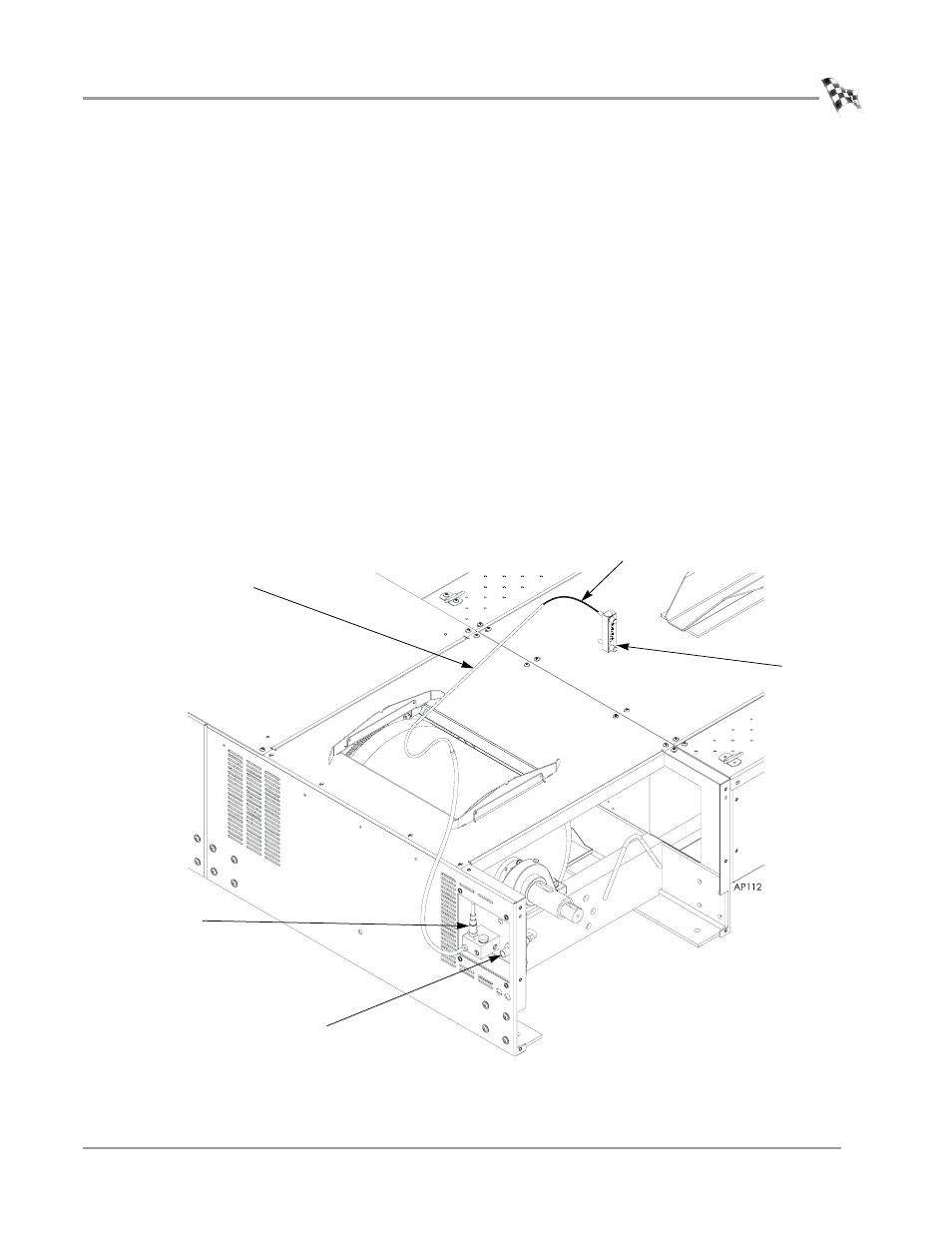

To ensure accurate readings, adjust the air flow as necessary to maintain 35L/min. If

you are unable to adjust the air flow to 35L/min. for each sample tube, clean the

pump then try to adjust the air flow again. Refer to “Pump Maintenance—On Dyno”

on page 2-9 for more information.

Adjust the air flow at the end of the exhaust probe to 35 L/min.

1

Attach six inches of the silicon tubing from the top port on the flow meter to the

copper sample tube.

2

Loosen the lock nut.

3

Turn on the air pump with the control panel.

4

Rotate the vacuum generator exhaust port until the flow meter reads

35 L/min.

5

Tighten the lock nut.

Note: Make sure not to rotate the vacuum generator exhaust port when

tightening the lock nut.

6

Remove the air flow meter and the six inches of silicon tube.

Note: Periodically check the air flow and adjust as necessary to maintain 35 L/min.

Figure A-4: Adjusting the Air Flow—On Dyno

copper sample

tube

flow meter

sensor

vacuum generator exhaust port

and lock nut

silicon tube