Pump maintenance-on dyno – Dynojet Compressed Air Air/Fuel Ratio Module User Manual

Page 25

U S I N G T H E A I R F U E L R A T I O M O D U L E

Air Pump Maintenance and Troubleshooting

Version 5

Compressed Air Air Fuel Ratio Module Installation and User Guide

2-9

P

UMP

M

AINTENANCE

—O

N

D

YNO

To ensure accurate readings, pump maintenance should be performed every six

months, or sooner, depending on usage. Periodically check the air flow and adjust as

necessary to maintain 35 L/min for each sample tube. If you are unable to adjust the

air flow to 35 L/min, clean the pump. Use a solvent to clean all pump pieces very

carefully.

1

Remove the eight screws securing the drum module panel to the dyno. Set the

screws and the panel aside. For more information on removing the panel, refer to

your dyno installation guide.

2

Remove the hose connecting the sensor block and the venturi body.

3

Remove the two screws securing the sensor block to the pump housing.

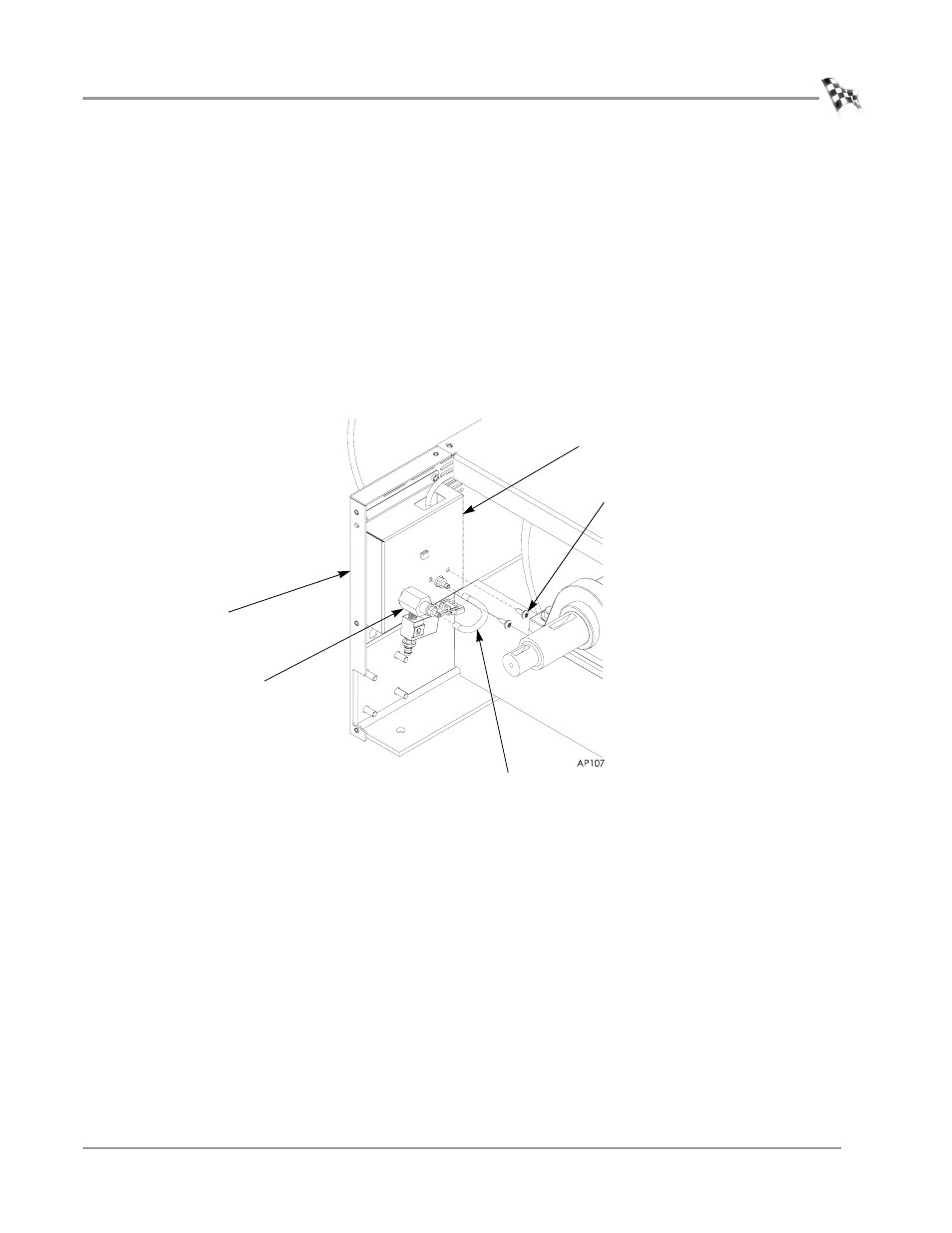

Figure 2-7: Remove the Screws Securing the Sensor Block

pump housing

sensor block

(not visible from this view)

sensor block screws

hose

venturi body