Routing cables—224xlc – Dynojet 224/4WD: Installation Guide User Manual

Page 38

In Ground Model 224 4WD Automotive Dynamometer Installation Guide

C H A P T E R 2

Routing Cables—224xLC

2-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

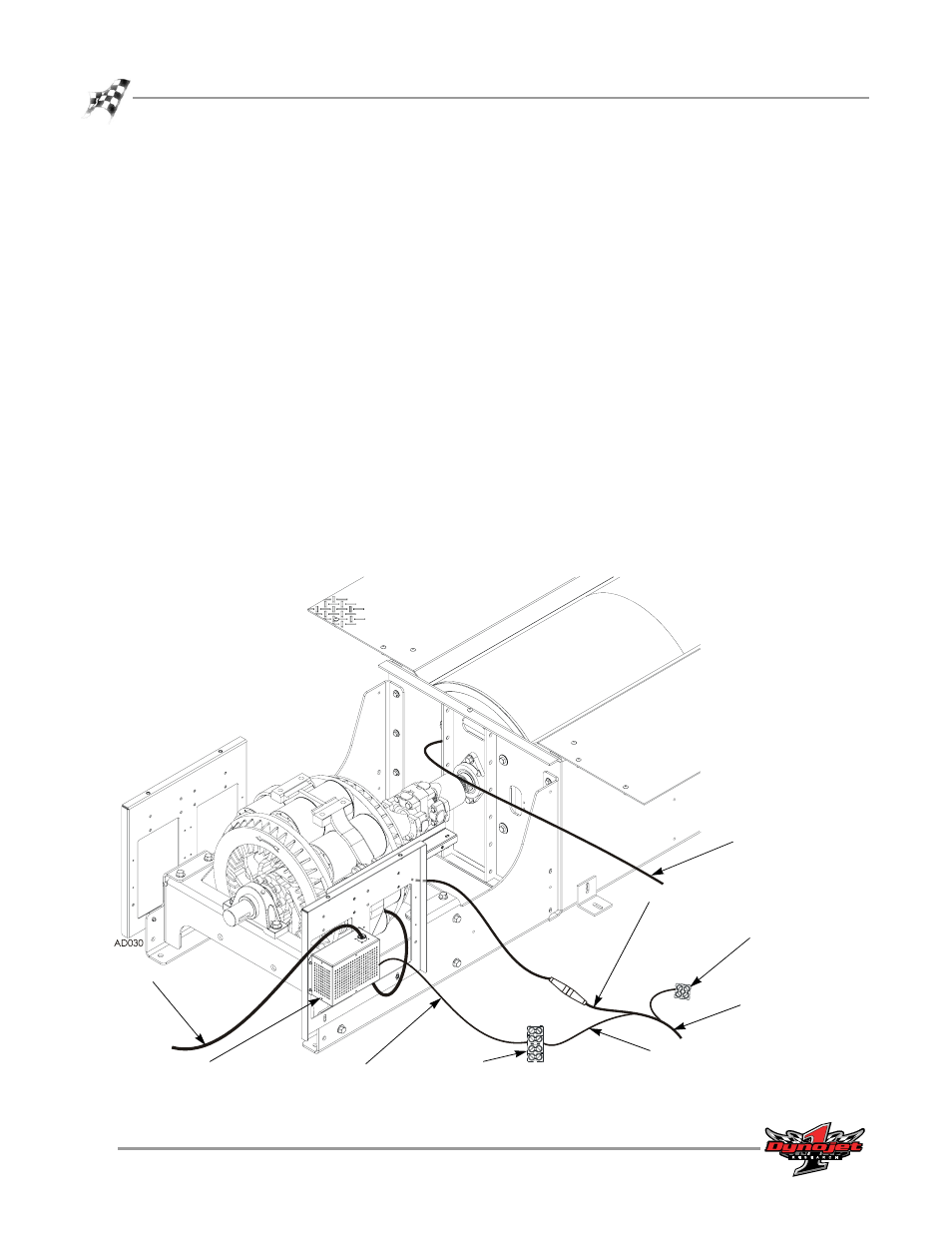

ROUTING CABLES—224XLC

Use the following instructions for routing cables when the 224 stationary dyno is

equipped with an eddy current brake.

1

Connect the temperature sensor cable from the eddy current brake to the

multi-purpose cable (C-3).

2

Connect the pickup card cable (B) to the pickup card.

3

Route the brake power cable from the eddy current brake through the pit cover

support and over to the Theta Controller (underneath).

4

Route the input power cable from the Theta Controller through pit cover

support, through the PVC conduit in the pit (not used by any other cables), and to

your power source.

Refer to the Eddy Current Brake Installation and User Guide for Model 224 Pit

Automotive Dynamometers (P/N 98215101) for more information.

5

Locate the four position terminal strip.

6

Connect the control cable from the Theta Controller to the terminal strip as

shown in Figure 2-16 on page 2-19.

7

Connect the load control cable (C-2) to the terminal strip as shown in Figure 2-16

on page 2-19.

Figure 2-15: Routing Cables—224xLC

control cable

input power cable

theta controller

pickup cable

from 4WD dyno

(C) multi-purpose

cable from 4WD dyno

C-3 temperature

sensor cable

C-2 load control cable

terminal strip

C-1 brake power

cable connected to

brake solenoid