Dynojet 224/4WD: Installation Guide User Manual

Page 36

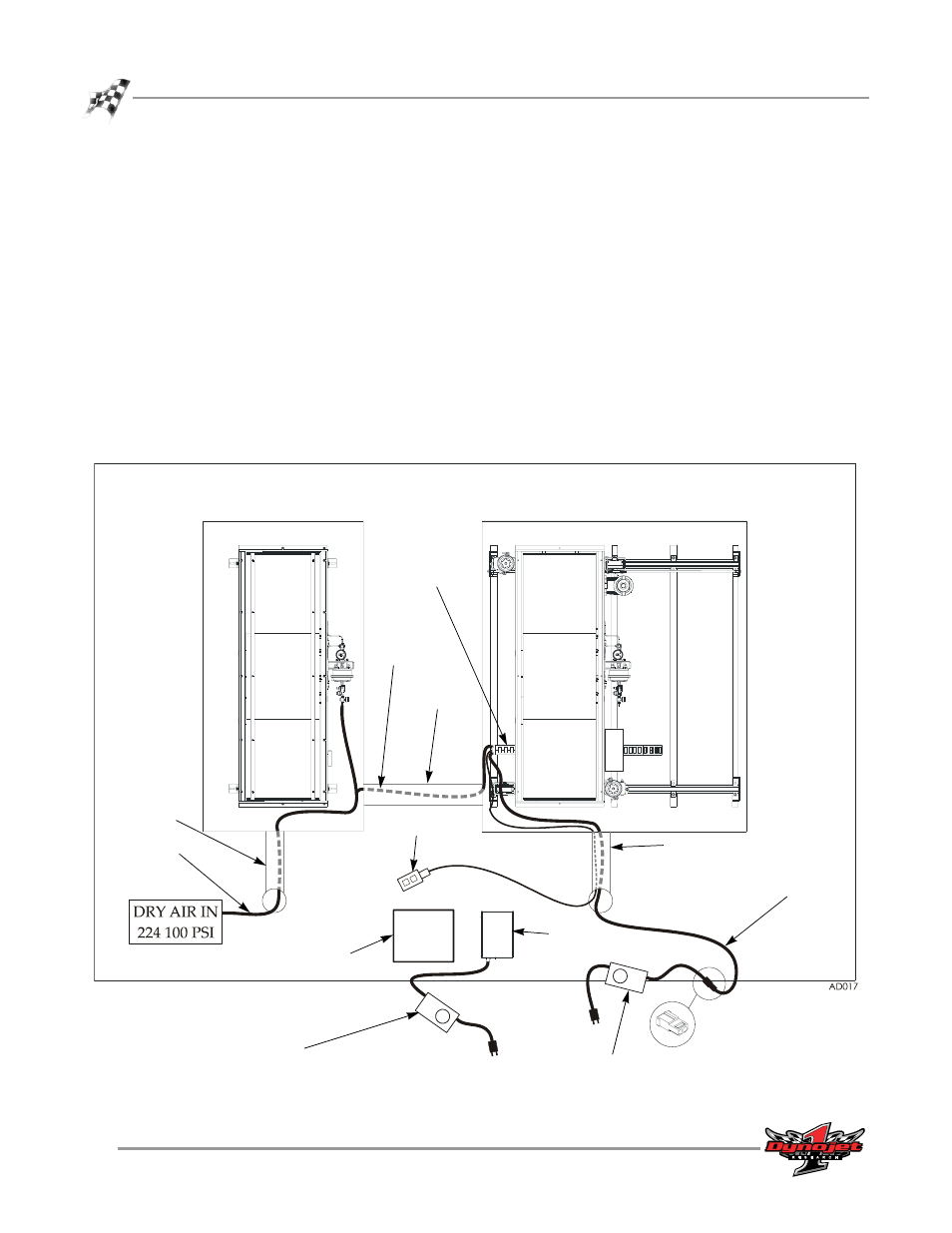

In Ground Model 224 4WD Automotive Dynamometer Installation Guide

C H A P T E R 2

Routing Cables

2-16

5

Route the air hose (F) from the cable track, through the conduit, and connect to

your clean, dry air supply at 100 psi.

Note: Verify the stationary dyno has clean dry air supplied to the air brake;

regulated to 100 psi for 224 stationary dynos and 60 psi for 248 stationary dynos.

The air brake comes installed with a hose barb for a 3/8-inch inside diameter air

hose. If your hose does not have an inside diameter of 3/8-inch then you will need

an air hose nipple (1/4-inch NPT) to connect your clean, dry shop air supply to

the dyno. Once the pressure is connected, the air brake is ready to use.

6

Route the power cable (D) from the cable track, through the conduit, and connect

to the power supply. Plug the power supply into your power source.

7

Connect the power supply to the dyno electronics. Plug the power supply into

your power source.

8

Route the dyno movement pendant cable (E) from the cable track, through the

conduit, and connect to the pendant.

Figure 2-13: Routing Cables Continued—224 224-4WD

pit

conduit

224 stationary dyno

224 4WD dyno

(D) power cable

pit conduit

computer

monitor

dyno

electronics

(E) dyno movement

pendant

cable track

(F) air

hose

(F) air

hose

power supply for

4WD dyno

power supply for dyno

electronics

pit conduit