B&M 70441 HOLESHOT 2400 User Manual

Page 3

3

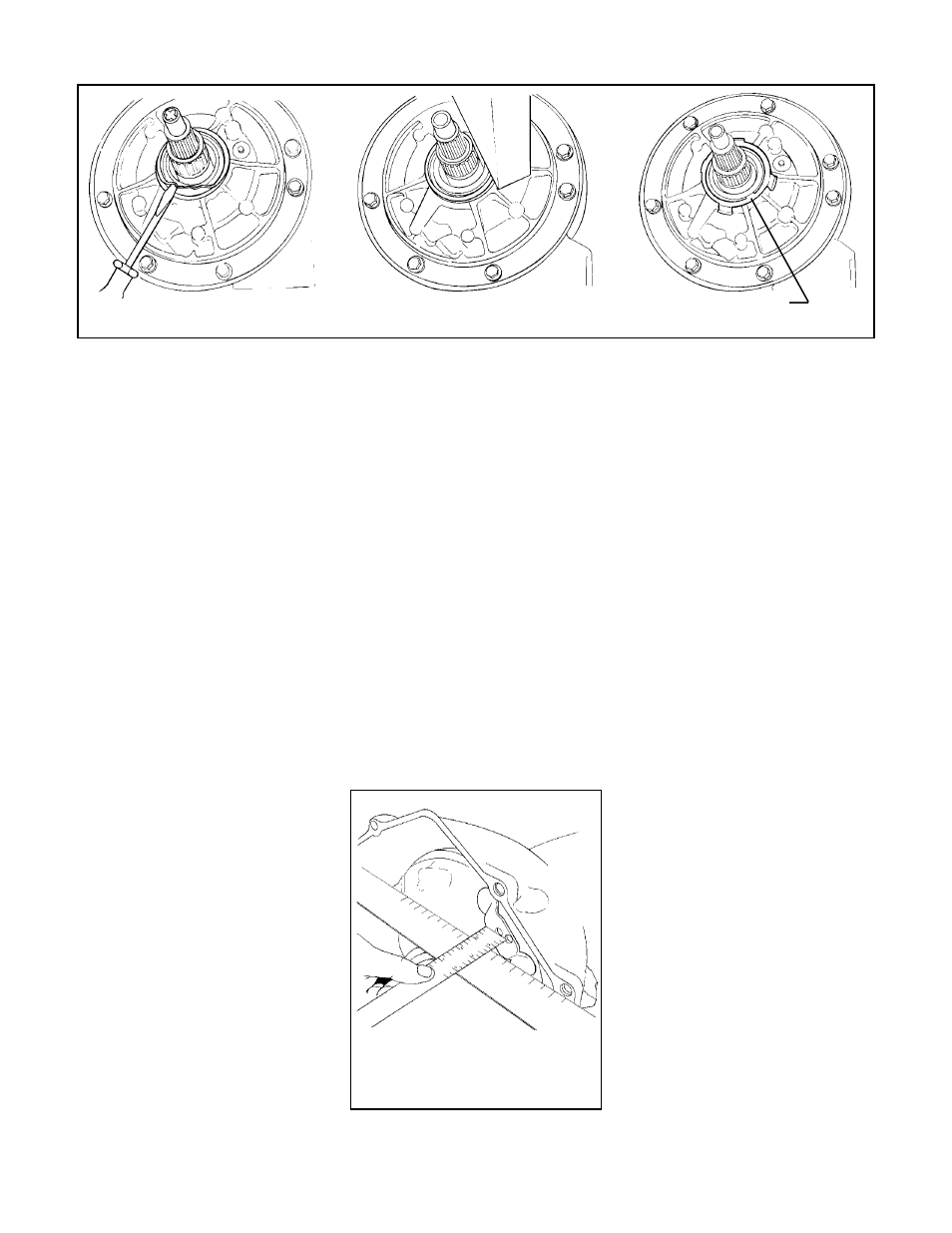

Fig. 5

Drive lug face must be at least 1"

inside front edge of bellhousing

Locate seal retainer tab

at 5 O'clock position

input shaft, reaction shaft and pump

drive tangs. Place a straight edge across

the bellhousing face and measure the

distance to the torque converter’s drive

lug face. The drive lug must be at least 1"

inside the bellhousing, see (Fig. 5). A

measurement of less than 1" indicates

the torque converter is not fully engaged

in the transmission. Continue to push in

and rotate the converter until you obtain

full engagement. If you install the trans-

mission without full converter engage-

ment, you will damage the oil pump.

STEP 15. Place the transmission in po-

sition on transmission jack. Make sure

the jack supports the transmission on a

wide area so the oil pan is not crushed.

Install the transmission / converter

against the engine. The transmission

should engage the dowel pins and sit flat

against the block with hand pressure

only. If the transmission does not sit flat

against the engine, the converter is not

fully engaged in the transmission or

some other interference problem exists.

Do not attempt to pull the transmission

up to the engine with the bellhousing

bolts as this can cause transmission or

torque converter damage.

STEP 16. Once the transmission is in

position against the engine, install the

bellhousing bolts and torque to 35 lb.ft. At

this point the torque converter should

turn freely. A tight converter indicates

improper engagement, distorted

flexplate or binding pilot hub. This condi-

tion must be corrected before going

any further.

STEP 17. Inspect transmission mount.

Worn, cracked or broken transmission

and/or engine mounts should be re-

placed. Raise transmission and install

crossmember assembly then tighten all

bolts. Install three (M10 x 1.5) flexplate to

converter bolts. Install the first bolt finger

tight then use the starter motor to “bump”

each drive lug into position. When all

three bolts are installed torque them to

47 Nm (35 lb.ft.).

STEP 18. Remove the oil pan and filter.

The filter suction tube O-ring may stick in

the pump body, if it does make sure to get

it out. Assemble two (2) O-rings on a new

oil filter. Some filters have a

preassembled seal on the suction tube,

if the filter you are using has a

preassembled seal do not use the O-

rings. Lubricate the suction tube seal

with clean transmission fluid and install

filter into the transmission.

STEP 19. Remove all old gasket mate-

rial from the pan and case flange. Install

a new pan gasket then assemble pan to

the transmission. Install ALL of the pan

bolts (install shifter cable bracket if

equipped) finger tight first then torque to

8 lb.ft. DO NOT use a sealant on the pan

gasket and don’t over torque the pan

bolts, this will damage the gasket and

cuase the pan to leak transmission fluid.

STEP 20. If your transmission is

Pump seal removal and installation

Fig. 4

alloy and can be easily damaged during

seal removal. We recommend the fol-

lowing seal removal procedure to mini-

mize the chance of damaging the pump

housing, see (Fig. 4).

1. Raise the transmission (or place on

bench) so that the seal is accessible

from the lower side of the transmission.

2. Using a common (flat) screwdriver

collapse the seals outer flange as

shown. Be careful not to damage the

housing with the screwdriver.

3. With the outer flange collapsed the

seal should pry out easily. Again take

care not to damage or gouge the hous-

ing. Once the seal is removed use a lint

free rag wrapped around a thin piece of

wood or other soft material, (to avoid

scratching the seal bore) to clean the

seal bore thoroughly.

STEP 11. Coat the outer diameter of the

new oil seal with “Locktite, 609” or

“Permatex, Secures Gears” cylindrical

retaining compound. Then using a small

block of wood between the seal and

hammer, carefully tap the seal evenly

into the housing until fully seated. If the

transmission was equipped with a seal

retainer, install the retainer onto the

housing as shown, see (Fig. 4).

STEP 12. Hold your B&M torque con-

verter against the crankshaft and

flexplate to check the pilot hub fit. The

converter pilot hub should fit in the crank-

shaft snugly with no excessive slop. A

tight fit indicates burrs or debris in the

crankshaft pilot diameter. The burrs or

debris can be removed with sand paper.

STEP 13. Pour 1 quart of transmission

Fluid into the B&M torque converter so

there will be some lubrication on initial

startup. Lubricate the converter’s pump

drive hub with clean transmission fluid.

STEP 14. Install the B&M torque con-

verter onto the transmission. Push the

converter in while rotating it to engage the

- 70440 Torque Converter, Holeshot 2000 GM 4L60E 1997 to 2003 Corvette, Camaro and Firebird with LS1 Engin 70422 Torque Converter, Traveler Converter GM TH700R4 1993 to 1996 30 Spline, 1984 to 1993 4L60E 30 Spline 70420 TORK MASTER 2000 30 SPLINE W/CLUTCH 70419 Torque Converter, Holeshot 2400 70417 HOLESHOT 2000 30 SPLINE W/CLUTCH 70415 TORQUE CONVERTER, HOLESHOT 2400