B&M 40263 SHIFT IMPROVER KIT User Manual

Page 8

8

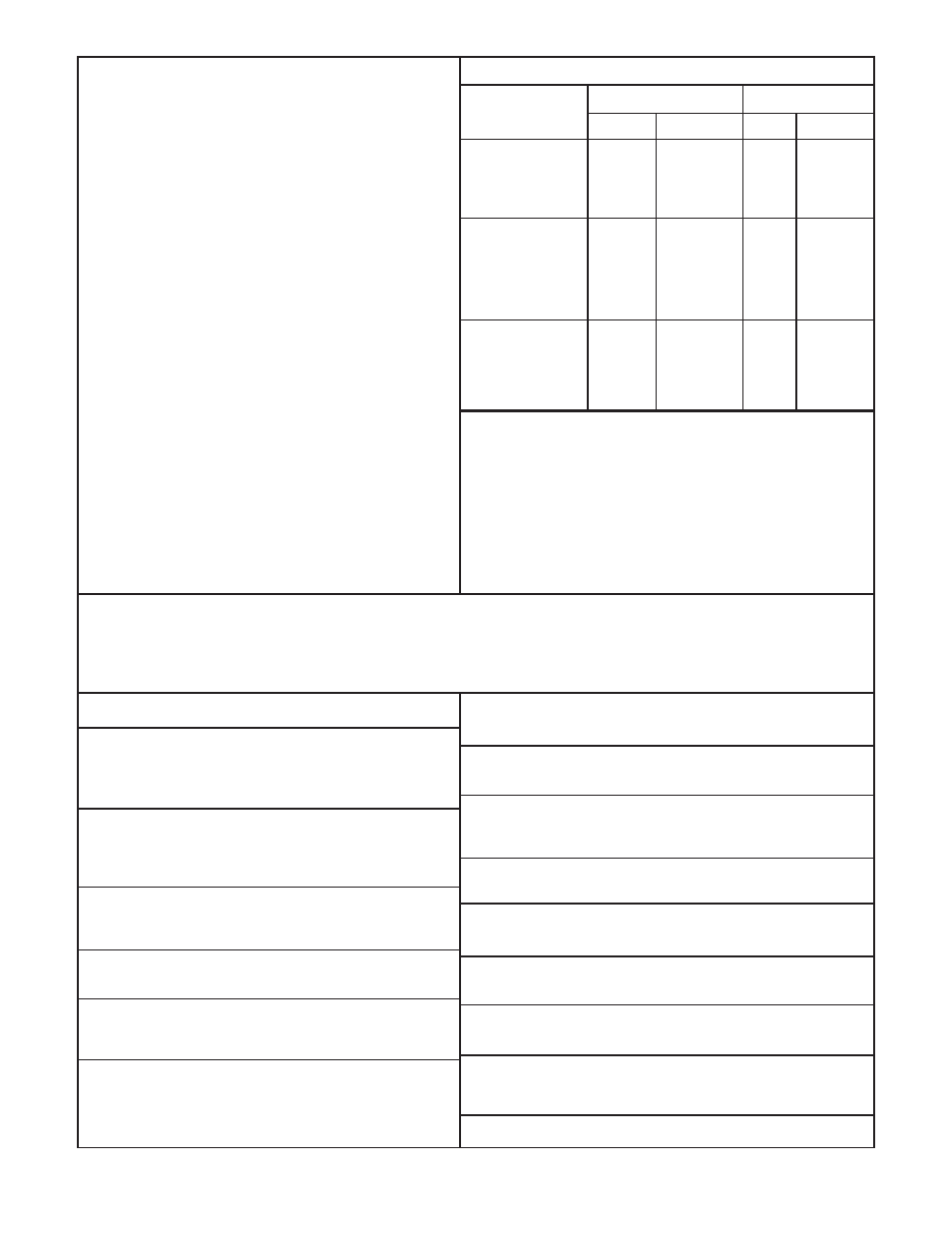

Oil Pressure Specifications

Selector

Line Pressure

TV Limit Pressure

Position

PSI

(kPa)

PSI

(kPa)

At idle

In Reverse

109-129

(751-890)

0

0

All Other Ranges

74-94

(510-648)

0

0

At W.O.T. (Stall)

In Reverse

3.8L & 4.9L

264-304

(1820-2096) 74-86

(510-593)

All other engines

275-315

1896-2172)

79-91

(545-627)

All Other Ranges

3.8L & 4.9L

200-220

(1379-1517) 74-86

(510-593)

All other engines

209-229

(1441-1579) 79-91

(545-627)

Line Pressure Test Results

Low at idle in all ranges: Check for low fluid level, clogged

or damaged filter, loose valve body bolts, stuck pressure

regulator valve, missing pressure regulator spring or oil

temperature too hot from excessive W.O.T. test.

Low at W.O.T. but O.K. at idle: Check for low oil level,

clogged filter, damaged or out of adjustment TV linkage,

Sticking TV or TV limit valve in valve body.

Slow initial engagement

Low line pressure

Fluid level low

Harsh initial engagement

Engine idle too high

Loose U-joint or engine mount

High line pressure

Sticking valves in valve body

2-3 accumulator valve stuck

No drive in any selector

Valve body leaking internally

position

Valve body bolts loose

Sticking valves in valve body

Manual valve pin not engaged

Fluid level low

No drive forward,

Worn or stuck governor

but has reverse

Valve body bolts loose

Sticking valves in valve body

Damaged 2-3 accumulator seal

Slips or chatters in 1

st

gear

TV linkage out of adjustment

(Selector in “OD”)

Low line pressure

Valve body bolts loose

Slips or chatters in 2

nd

gear

Defective intermediate clutch

(Selector in “OD”, OK in 1

st

)

Sticking valves in valve body

Slips or chatters in Reverse

Low line pressure

Valve body bolts loose

Starts in 2

nd

or 3

rd

Sticking governor

Sticking valves in valve body

Cross channel leaks between

case or separator plate

and valve body

Incorrect shift points

TV linkage out of adjustment

Worn governor

Sticking valves in valve body

NO 1-2 upshift

TV linkage out of adjustment

Governor valve sticking

Sticking valve in valve body

Mushy 1-2 shift

Out of tune engine

Defective intermediate clutch

TV linkage out of adjustment

Low line pressure

No 2-3 upshift

Defective direct clutch

Convertor damper hub broken

Sticking valve in valve body

Mushy 2-3 upshift

Defective 2-3 accumulator

piston or seals

Low line pressure

Mushy or rough

Out of tune engine

3-4 upshift

Defective OD band or reverse drum

TV linkage out of adjustment

No forced down

Defective clutch or band

shifts

TV linkage damaged or out of adjustment

Sticking valve in valve body

Transmission

Overheated engine

overheats

Restriction in cooler or lines

Converter overrun clutch seized

Sticking valves in valve body

Transmission noise

Relief valve buzzing

Oil pump cavitation

TROUBLESHOOTING GUIDE FOR THE FORD AOD TRANSMISSION

The troubleshooting guide is intended to help you identify possible causes of malfunctions that could be related to

incorrect assembly or adjustment of the transmission hydraulic system (valve body and accumulator) and or mechanical

controls. We recommend that you obtain an AOD service manual for problems related to the torque converter or

transmission hard parts.

Line Pressure check

*On the AOD transmission two pressure readings

must be taken: One at idle (closed throttle, Zero TV

Press.) and another at wide open throttle (W.O.T.,

Full TV Press.).

*Engine and transmission should be at normal operat-

ing temperature for test.

*During test at W.O.T. (stall) the wheels must be

locked to prevent any vehicle motion.

*DO NOT operate at W.O.T. Stall for more than 10

seconds at a time, followed by at least 2 minutes in

Neutral at 1000 RPM to cool the oil.

*Connect a 0-300 PSI (0-2000 kPa) pressure gage to

the line pressure port located just above the control

levers on the right side of the transmission (See Fig.

8). The gage hose must be long enough to read gage

while operating engine.

*Connect a 0-100 PSI (0-690 kPa) gage (300 PSI gage

will work if it’s all you have) to the TV Pressure tap

on the right hand side of the transmission (See Fig.

8). The gage hose must be long enough to read gage

while operating engine.

*Idle pressure must be read with throttle off the fast

idle cam.

*Pressures listed apply to stationary vehicle only. In

3

rd

and 4

th

gears line pressure is lower (cut back) than

shown for “all other ranges”.