Filling the container – Taylor-Wharton XL-55HP (with dual regulators) User Manual

Page 9

FILLING THE CONTAINER

Cryogenic liquid containers must always be filled by weight to ensure there is enough gas

head space (ullage) for liquid to expand as it warms. Using the procedure bellow, first

determine the proper filled weight of each container. The weight derived is then used in

either the Pump Transfer of Pressure Transfer filling procedures that follow.

Determining Proper Fill Weight

1. Visually inspect the container. Do not attempt to fill containers with broken or missing

components.

2. Move the container to a filling station scale and weight it both with and without the fill

hose attached to determine the weight of the fill line assembly. The difference is the fill

line weight.

3. To determine the weight, at which the fill should be stopped, add the desired filling

weight (from the table below), the transfer line weight, and the Tare Weight from the

containers data plate.

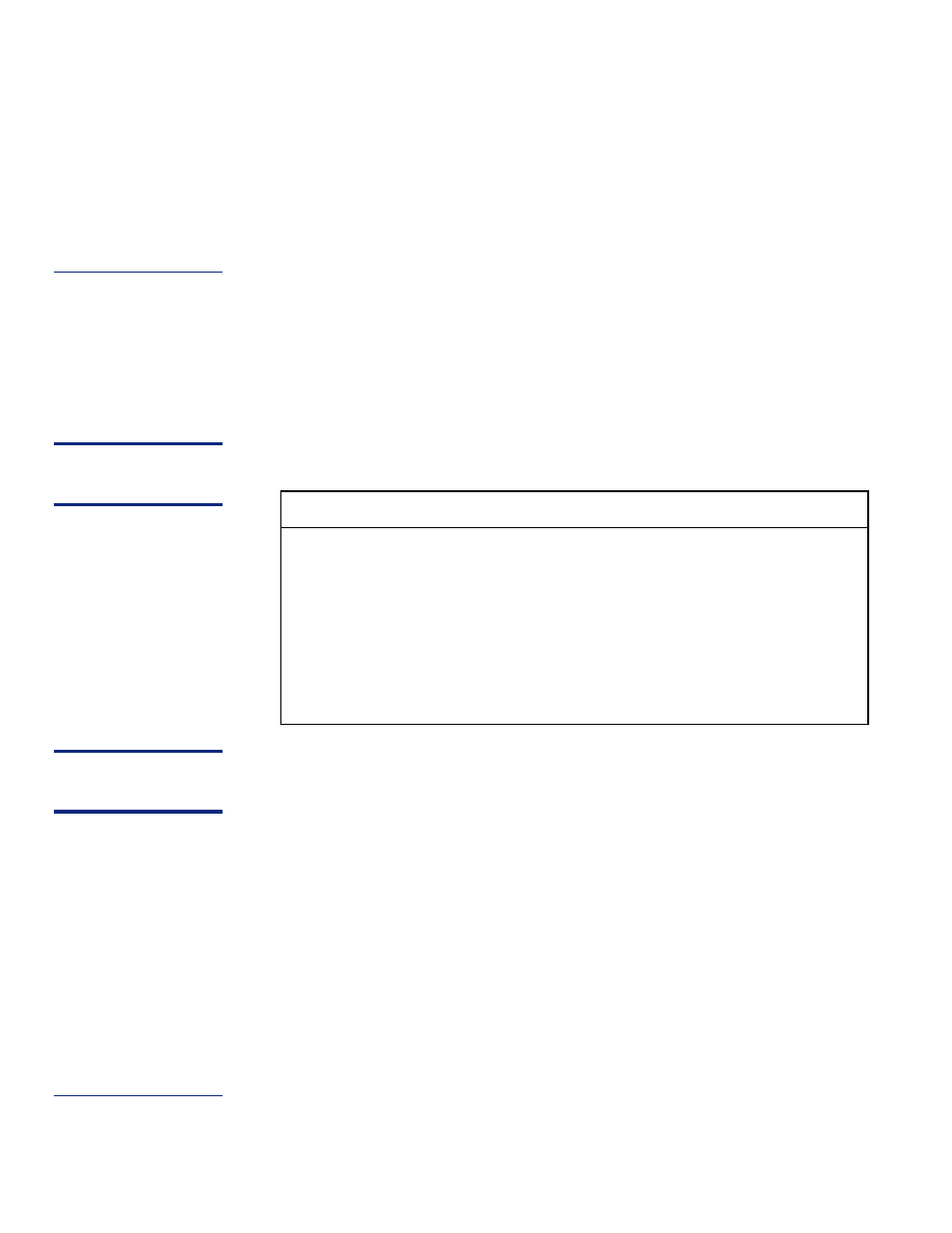

FILLING WEIGHTS

XL-45HP

XL-50HP

XL-55HP

XL-50VHP

ARGON

438 lb. (199 kg)

467 lb. (212 kg)

518 lb. (235 kg)

443 (201 kg)

CARBON

387 lb. (176 kg)

414 lb. (188 kg)

458 lb. (208 kg)

381 lb. (173 kg)

DIOXIDE

NITROGEN

252 lb. (114 kg)

269 lb.(122 kg)

298 lb. (135 kg)

240 lb. (109 kg)

NITROUS

368 lb. (167 kg)

393 lb. (178 kg)

435 lb. (197 kg)

N/A

OXIDE

OXYGEN

360 lb. (163 kg)

385 lb. (175 kg)

426 lb. (193 kg)

364 lb. (165 kg)

Solid CO

2

(Dry Ice) Formation - Carbon dioxide may form into the solid phase (dry ice)

if the saturated pressure of the liquid is allowed to drop below 70 psig (4.8 bar/483 kPa.)

In carbon dioxide service, the pressure in a XL-45Hp/50HP/55HP/50VHP must be main-

tained above this pressure to ensure a solid block will not form inside the container. If a

container is being filled with CO

2

, it may be necessary to pressurize the container with

gaseous CO

2

before beginning the fill.

Pressure Transfer Filling Method

Filling a liquid cylinder using the pressure transfer method is common for 22 psig (1.5 bar/

152 kPa) service where the product is used for refrigerant purposes. This method may

also be used for higher-pressure cylinders to increase liquid holding time. A fill is accom-

plished by first establishing a pressure difference between source vessel and the XL-

45Hp/50HP/55HP/50VHP (higher pressure at the bulk vessel). The pressure differential

will then push the liquid from the storage vessel to the container being filled. This method

is employed when no transfer pump system is available, or if a greater control over liquid

temperature is desired.

Filling the container is accomplished through the LIQUID valve while the VENT valve is

open or partially open to control product pressure. Careful control of pressure will control

the amount of heat retained in the liquid. Lower pressure results in colder liquid trans-

ferred to the container and increases, or lengthens, product holding time.

NOTE:

The weight

calculation includes

the weight of residual

liquid and is

applicable to both

Pressure Transfer and

Pump Transfer filling

methods.

WARNING:

Filling operations

should take place only

in well ventilated

areas. Accumulations

of product gas can be

very dangerous (refer

to the safety

precautions in the

front of these

instructions). Maintain

adequate ventilation

at all times.

NOTE:

If the pressure in the

container is somehow

lost, the dry ice block

that forms may be

thawed by

pressurizing the

cylinder to 280 psig

(19.3 bar/1931 kPa)

with carbon dioxide

liquid and gas from an

external source, and

allowing several days

at this pressure to

thaw the cylinder.

9