Full view contents gauge maintenance – Taylor-Wharton XL-55HP (with dual regulators) User Manual

Page 16

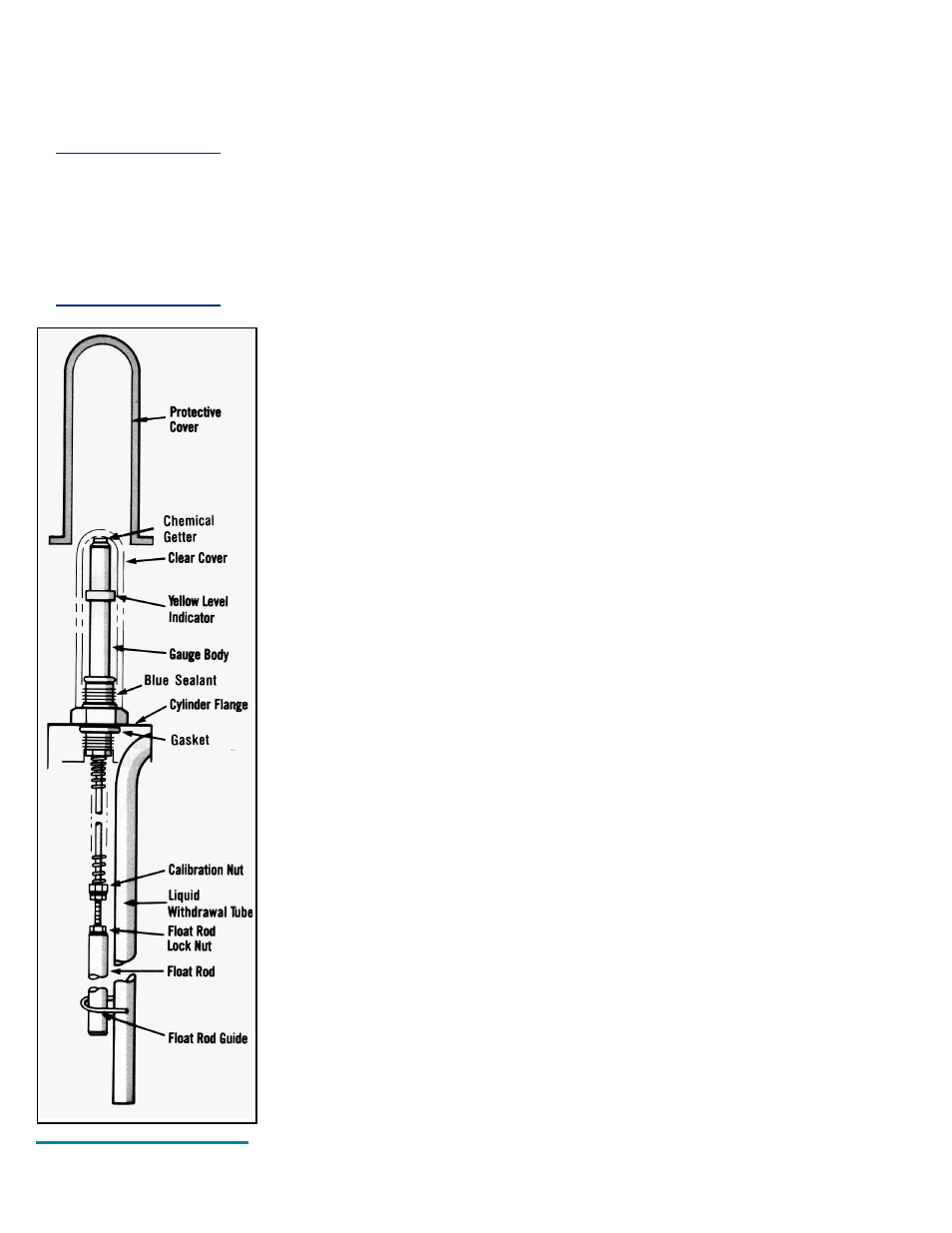

FULL VIEW CONTENTS GAUGE MAINTENANCE

The content of these containers is measured with the Full View Contents Gauge. The

device consists of the gauge assembly beneath a clear plastic protective cover. When the

gauge is assembled, a level indicator ring is magnetically coupled to the top of a float rod

and moves up or down with the changing level of liquid in the container. The clear cover

over the gauge body and level indicator is sealed at assembly to resist fogging of the

gauge. This seal should never need to be broken.

Removing the Full View Contents Gauge

1. Vent all pressure from the container.

3

2. Remove the protective cover by removing three bolts from the base of the cover.

3. Unscrew the gauge body using a wrench on hex fitting as base of the indicator.

4. Life the entire gauge assembly free of the container. The gauge assembly is long and

may be very cold. Gloves should be used to protect your skin.

Calibration Procedure for Liquid Level Contents Gauges

1. You will need a column of water approximately 4 ft. (1.2 m) tall. A clear plastic tube 2.0

in. (51 mm) dia. with a cap glued to one end is perfect. Place an oxygen service

contents scale sleeve (P/N GL50-9C43) over the sight tube.

2. Support the gauge assembly by holding the base of the indicator tube. Care must be

taken to prevent interference with the spring action or from misaligning the scale sleeve.

Immerse the aluminum float rod below the water level as illustrated. The gauge assem-

bly must be held vertically and the rod must not touch the side or bottom of the tube.

The yellow level indicator of the gauge should indicate a full level reading with the

oxygen scale.

If the gauge fails to indicate a full liquid level, the assembly is to be removed from the

water, calibrated and retested.

To change calibration, loosen locking nut away from brass calibration nut and turn the

threaded rod with respect to the calibration nut.

If the rod is turned clockwise (to the left) with respect to calibration nut, the exposed

portion of rod becomes longer and the gauge yellow band will be lowered.

To raise the yellow band, turn rod counterclockwise. The exposed portion of rod becomes

shorter. Once you have adjusted calibration, recheck for proper setting. (See illustration.)

After proper setting has been obtained, lock down nut against calibration nut.

3. Once the gauge assembly has been calibrated to read full in water, it must be verified that

it reads empty when the aluminum float rod is suspended in the air. The yellow indicator

must be as close to the bottom as possible (inner rod will be firmly bottomed out).

If calibration is required to make the gauge read empty in air, it must be rechecked in

water.

4. After calibration, you will need to follow contents gauge installation to reinsert gauge.

Be sure to dry the assembly before reinserting into the cylinder to prevent ice build-up

that could restrict movement to catch on the guide ring inside the cylinder.

3

For containers in C0

2

service, see caution on releasing container pressure at the beginning of the

Maintenance section.

WARNING:

Cold surfaces should

never be handled

with bare skin. Use

gloves and other

protective clothing

when performing this

procedure.

Full View Contents

Gauge

16