Maintenance procedures – Taylor-Wharton XL-55HP (with dual regulators) User Manual

Page 12

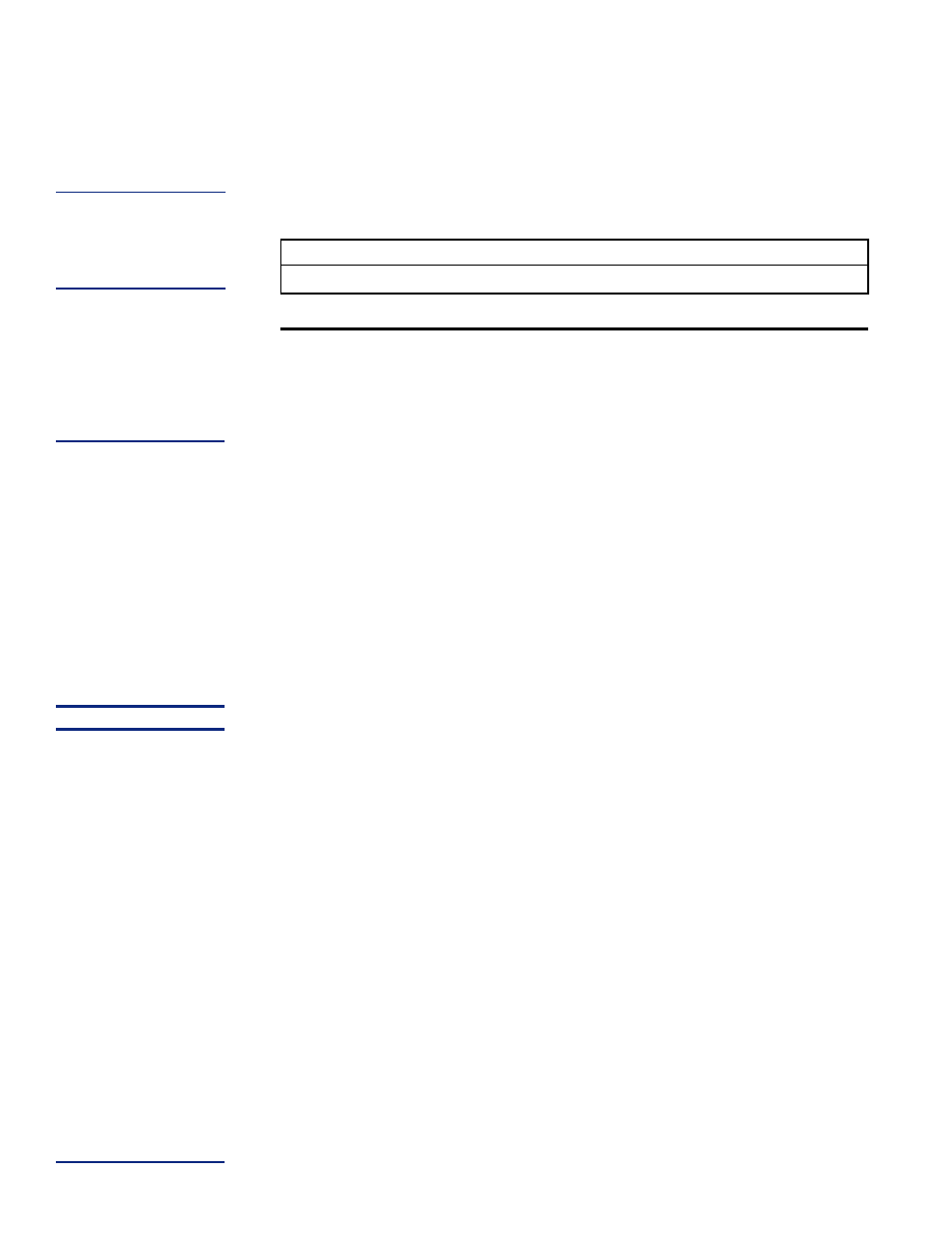

VENT TEE CHART

The vent tee chart connects to a transfer hose to complete a fill line kit. Each assembly

includes a 3/8 in. pipe connector to CGA fitting with a 350 psig (24 bar/2413 kPa) relief

valve, and a ball-type dump valve.

Service

CGA Connection

Part Number

Inert (N

2,

Ar)CGA 295

GL50-8C60

Read the Safety Precautions in the front of this manual before attempting any repairs on

these containers. Also follow these additional safety guidelines while performing con-

tainer maintenance.

Never work on a pressurized container. Open the vent valve as a standard practice

during maintenance to guard against pressure build-up from residual liquid.

Use only repair parts cleaned for oxygen service. Be certain your tools are free of oil

and grease. This is a good maintenance practice, and helps ensure you do not create a

combustion hazard when working on containers for oxygen or nitrous oxide service.

Leak test connections after every repair. Pressurize the container with an appropriate

inert gas for leak testing. Use only approved leak test solutions and follow the manufacturers

recommendations. Snoop Liquid Leak Detector is one approved solution, it is available

from: Nupro Co., 4800 E. 345

th

St., Willoughby, Ohio, 44094 U.S.A.

CONVERTING A CONTAINER TO A DIFFERENT GAS SERVICE

XL-45HP/50HP/55HP/50VHP cylinders may be converted from one service to another

within the confines of the argon, carbon dioxide, nitrogen, nitrous oxide, and oxygen

service for which the containers are designed. Conversion consists of changing end con-

nections at the USE, LIQUID and VENT valves; then changing the liquid level gauge scale

by changing its plastic cover; and revising product decals. Parts are available in kit form

for each gas service as illustrated in the following table.

Service Change Procedure

Before removing any parts, empty the container and open the vent valve to prevent any

pressure build-up in the unit.

1. Remove the LIQUID, VENT and USE end fittings, one at a time, with standard wrenches.

Install new fittings from the Gas Service Change Kit, using Teflon tape or another

oxygen-compatible thread sealant.

2. Remove the protective cover over the liquid level gauge. Replace the contents scale

with the scale for the new gas service from the service change kit, then replace the

protective cover.

3. Install new fittings for the USE, VENT and LIQUID connections from the Gas Service

Change Kit. Leak test the fittings you just replaced, and change the gas service de-

cals to complete the conversion.

WARNING:

Never put any liquid

cylinder into another

service once it has

been in CO

2

service.

MAINTENANCE

PROCEDURES

WARNING:

For O

2

users: Residue

of leak detectors

solutions can be

flammable. All

surfaces to which the

leak detector solutions

have been applied

must be adequately

rinsed with potable

water to remove all

traces of residue.

Reference CGA G-4,

Section 5.9

CAUTION:

Carbon dioxide may

form into the solid

phase (dry ice) if the

pressure of the liquid

is allowed to drop

below 70 psig (4.8 bar/

483 kPa). Pressure in

the container must be

maintained above this

value to ensure a solid

block of CO

2

will not

form inside the

container. Before

performing

maintenance on an

XL-45HP/50HP/55HP/

50VHP in CO

2

service,

the contents must be

transferred to another

container so that

container pressure

can be released.

12