Taylor-Wharton XL-55HP (with dual regulators) User Manual

Page 7

The PRESSURE BUILDING Valve This valve isolates the liquid in the bottom of the

container to the Dual Pressure Building/Economizer Regulator. This valve must be open

to build pressure inside the container.

The VENT Valve - This valve controls a line into the headspace of the container. It is used

during the fill process. The VENT valve acts as a fill point during the pump transfer, or to

vent the head space while liquid is filling the inner container during the pressure transfer fill

through the LIQUID Valve.

The Pressure Gauge - The pressure gauge displays the internal container pressure in

pounds-per-square-inch or in kiloPascals.

The Full View Contents Gauge The container contents gauge is a float type liquid

level sensor that indicates container liquid content through a magnetic coupling to a

yellow indicator band. This gauge is an indication of approximate container contents only

and should not be used for filling; liquid cylinders should be filled by weight.

Relief Devices These cylinders have a gas service relief valve and inner container

bursting disc with settings of 350 psig (24 bar/2412 kPa) and 525 psig (36 bar/3620 kPa)

respectively for the XL-45HP/50HP/55HP and 500 psig (34 bar/3447 kPa) and 750 psig

(52 bar/5171 kPa) for the XL-50VHP. Relief valves of 230 psig (16 bar/1586 kPa) and 22

psig (1.5 bar/152 kPa) are available if medium pressure operation is desired. Alternate

pressure building regulator and economizer settings are required if medium-pressure re-

lief valves are installed.

CAUTION:

When withdrawing

liquid gas from the

cylinder, the capacity

of the internal

vaporizer can be

exceeded. If gas is

withdrawn at rates

greater than the

vaporizer capacity,

liquid or very cold gas

will be discharged.

Severe damage to

external equipment

could result from the

extreme cold.

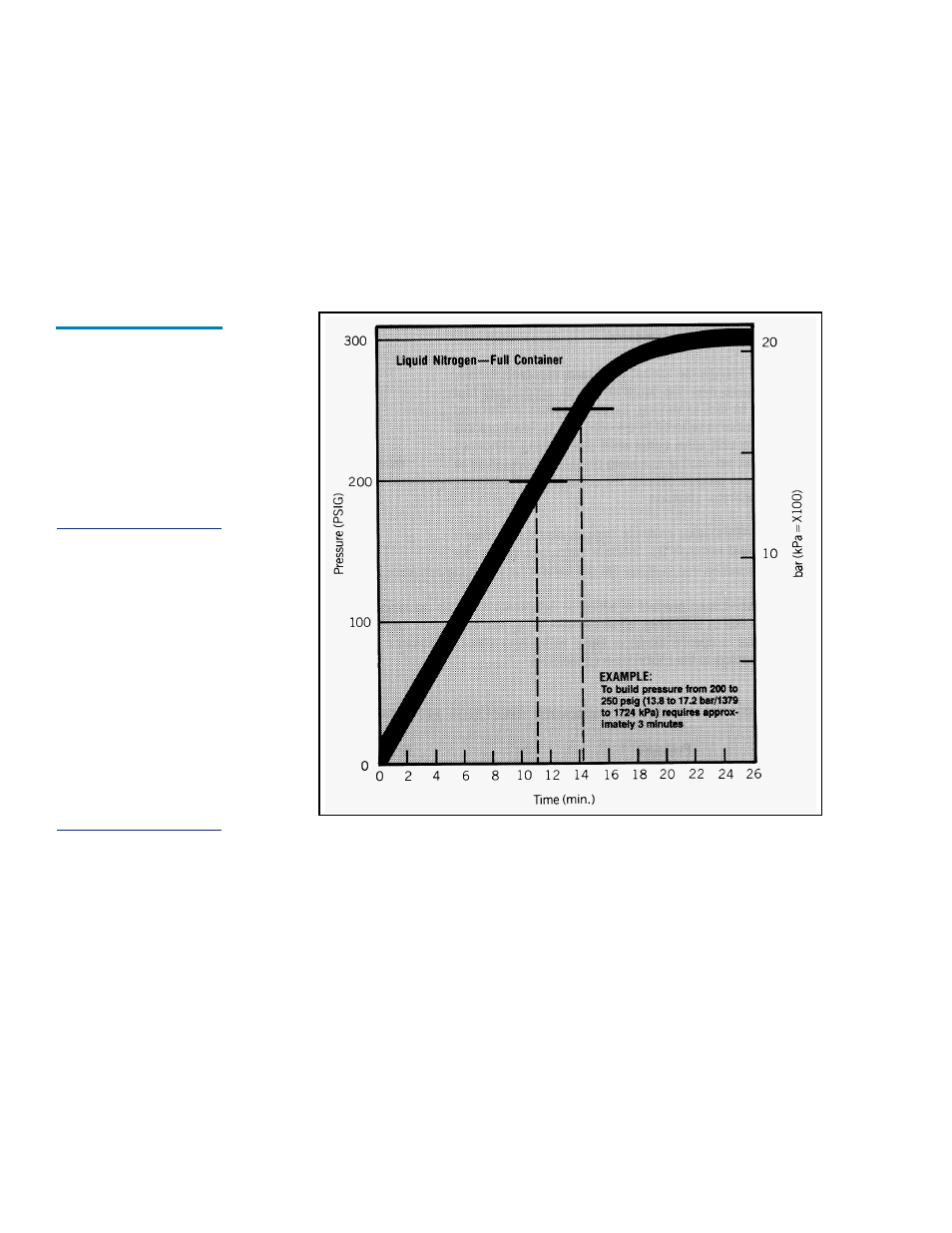

Pressure

Building Rates

Graph

7