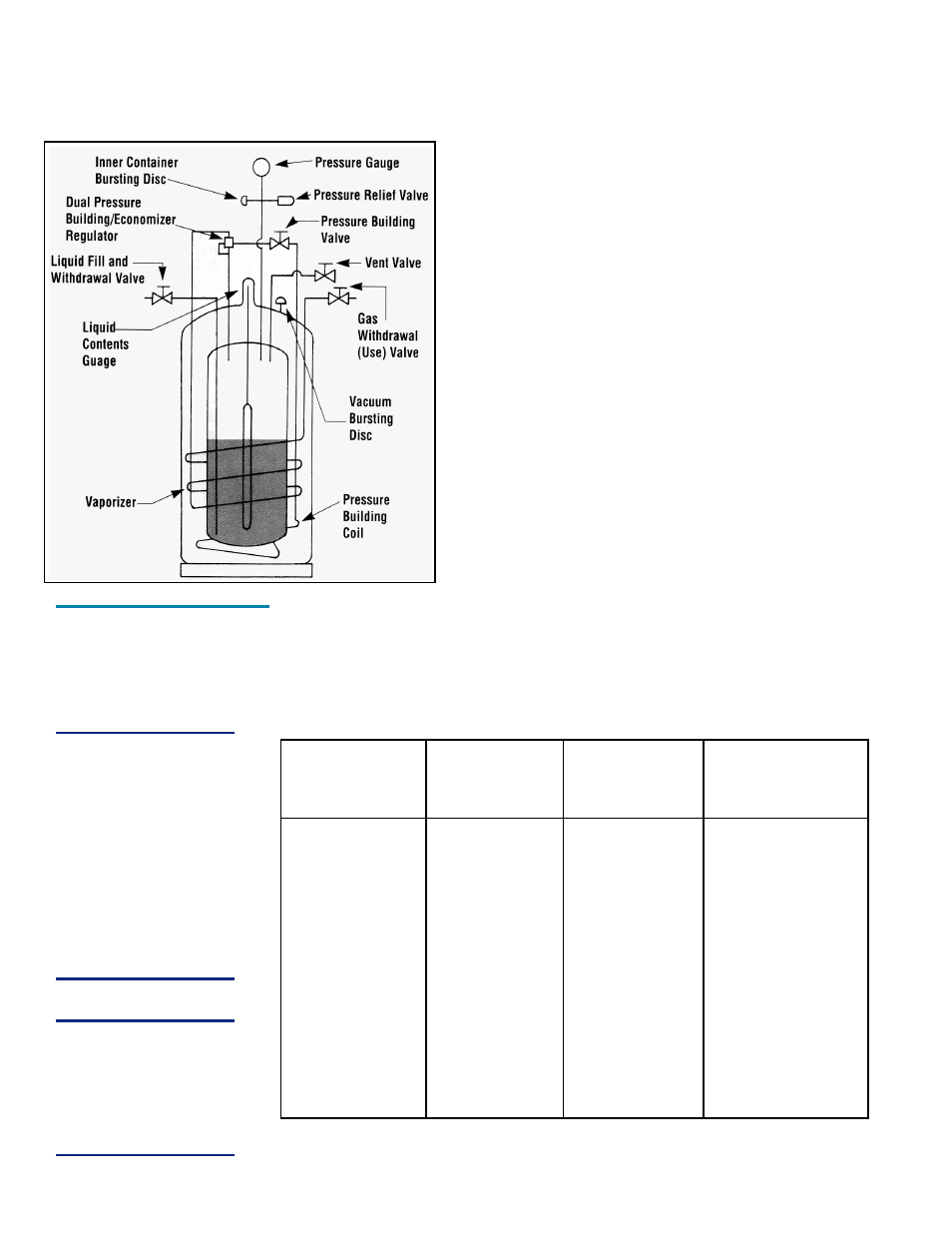

Taylor-Wharton XL-55HP (with dual regulators) User Manual

Page 6

inner container is vaporized in a heat exchanger which is inside

the outer casing. The expanding gas is fed into the upper sec-

tion of the container to build pressure. The resulting process will

drive either the liquid or gas delivery system.

Pressure Building is not normally required unless container pres-

sure drops below the gas output pressure desired. If, for ex-

ample, the container pressure gauge reads 250 psig (17.2 bar/

1724 kPa), and your gas pressure requirement is 270 psig (19

bar/1860 kPa), and the pressure building valve may be opened

to build container pressure to 300 psig (20.7 bar/2068 kPa).

Economizer An economizer circuit withdraws gas preferen-

tially from the head space over the liquid container gas that

would otherwise be lost to venting. Excess pressure in the head

space of the container is relieved by allowing gas to flow from

this area directly to the USE valve outlets while gas is being

withdrawn from the container; yet normal operating pressure is

preserved to ensure uninterrupted product delivery. The econo-

mizer is automatic and requires no operator attention.

The USE Valve This valve controls the gas outlet that allows

product withdrawal through the internal vaporizer. It has the re-

quired CGA connection that matches the gas service for which

the container is configured.

The LIQUID Valve Liquid product is added or withdrawn from the container through the

connection controlled by this valve. It has the CGA fitting that is required for liquid line

connections. The valve is opened for fill or liquid withdrawal after connecting a transfer

hose with compatible fittings to the LIQUID line connection.

RELIEF VALVES AND RECOMMENDED REGULATOR SETTINGS

Relief

Pressure

Normal

Valve

Building

Economizer

Operating

Setting

Setting

Setting

Range

22 psig

N/A

N/A

0-22 psig

1.5 bar

N/A

N/A

0-1.5 bar

152 kPa

N/A

N/A

0-152 kPa

230 psig

125 psig

145 psig

75-175 psig

16 bar

8.6 bar

10 bar

5-12 bar

1586 kPa

862 kPa

1000 kPa

517-1207 kPa

350 psig

300 psig

320 psig

200-350 psig

24 bar

20.7 bar

22 bar

13.8-24 kPa

2413 kPa

2068 kPa

2206 kPa

1379-2413 kPa

500 psig

400 psig

420 psig

300-600 psig

34 bar

28 bar

29 bar

20.7-41 bar

3447 kPa

2758 kPa

2896 kPa

2068-4137 kPa

XL-45HP/XL-50HP/

XL-55HP and XL-

50VHP Flow

Diagram

NOTE:

The economizer and

pressure building

functions are controlled

by a single dual action

regulator. The pressure

delta between the

pressure building

setpoint and the

economizer setpoint is

approximately 20 psig

(1.4 bar/138 kPa). This

delta cannot be altered.

WARNING:

Never use the Dual

Pressure Building/

Economizer Regulator

or Relief Valve for the

XL-50VHP on any other

container.

6